10

Engineering Data

Selection

The first consideration in any fan

selection is the amount of air to be

moved and the resistance to this air

movement. Air volume requirements are

established through specific codes or

accepted industry standards. Once the

air volume is known, system resistance

can be determined by summing up the

losses through the system components.

Duct layout, duct size, coils, filters,

dampers, and fan accessories all affect

system resistance. ASHRAE Guide and

Data Books and manufacturer’s data

on individual system components are

common sources of information available

to the system designer.

In most applications, several fans may

meet the required airflow and system

resistance conditions. An optimum fan

selection requires evaluation of alternative

fan types and fan sizes, as they relate

to initial cost, operating cost, available

space, and allowable sound levels. The

relative importance of these facts varies

with each system.

Two types of wheels are available:

1. Backward-inclined or airfoil wheels

turn at twice the speed of forward-

curved fans and feature:

•Higher operating efficiencies

•A non-overloading horsepower

curve which reaches a peak

near the middle of the normal

operation range

•Stronger wheel design allowing for

operation at higher static pressures

2. Forward-curved wheels typically

have lower performance capabilities

compared to the backward inclined

and contain:

•Overloading type wheel (meaning

that changes in performance

can result in significant brake

horsepower changes)

•Forward-curved wheels have lower

sound levels

Comprehensive air performance data for

these utility fans can be found in the fan

tables and fan curves section, starting on

page 15.

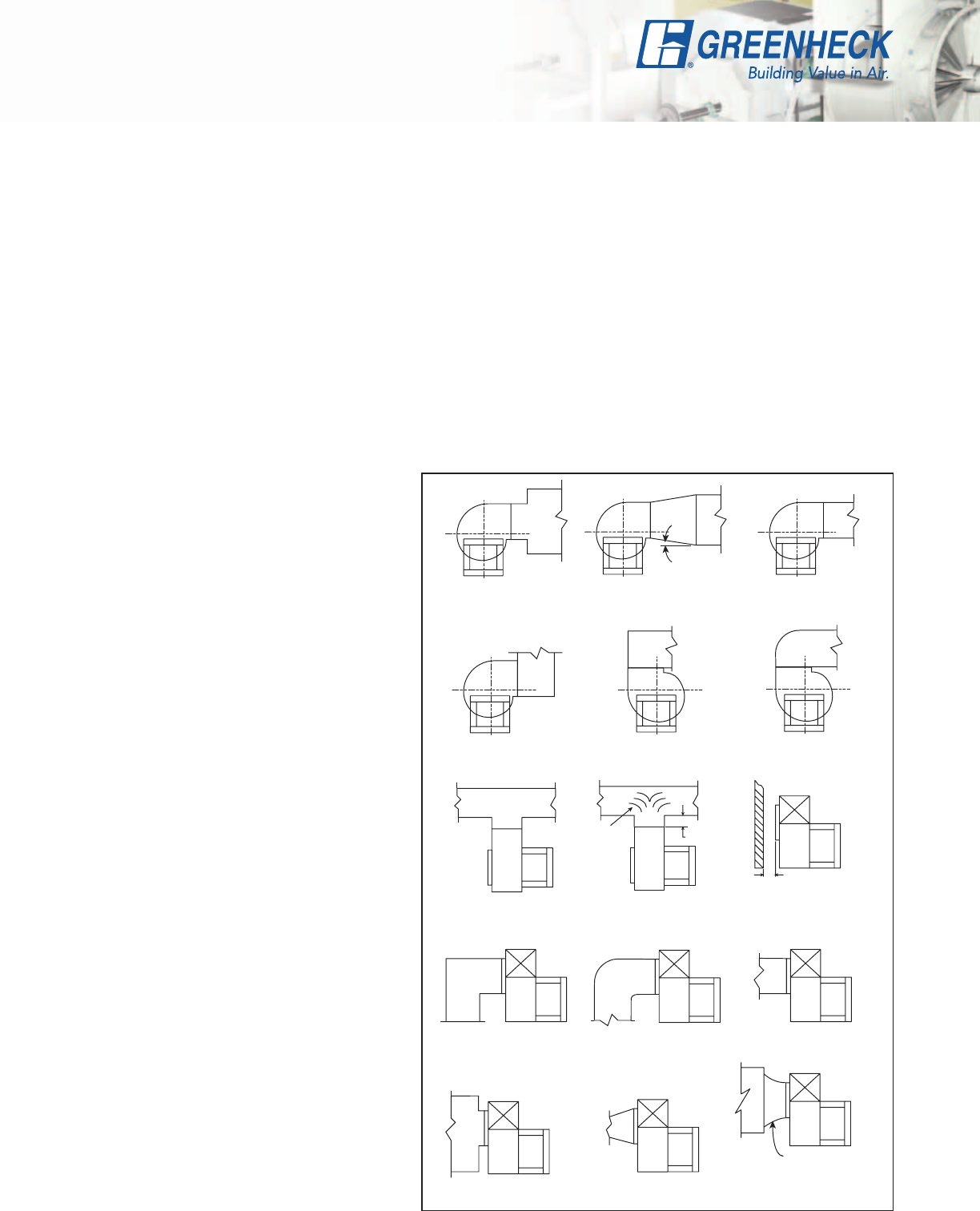

Effects of Installation on Performance

Fan ratings presented in the performance tables and curves

of this catalog are in accordance with AMCA Standard 210

“Laboratory Methods of Testing Fans for Aerodynamic

Performance Rating.” The AMCA test procedure utilizes an open

inlet and a straight outlet duct to assure maximum static regain.

Any installation with inlet or discharge configurations that deviate

from this standard may result in reduced fan performance.

Restricted or unstable flow at the fan inlet can cause pre rotation

of incoming air or uneven loading of the fan wheel yielding large

system losses and increased sound levels. Free discharge or

turbulent flow in the discharge ductwork will also result in

system effect losses.

The examples below show system layouts and inlet and

discharge configurations which can affect fan performance.

GOOD

POOR

POOR

FAIR

7

o

MAX.

POOR

FAIR

POOR

FAIR

One

Impeller

Dia.

GOOD

Should be at least

1/2 Impeller Dia.

FAIR

Not Greater than

60

o

Including Angle

POOR

POOR

FAIR

GOOD

POOR

Turning

Varies