Damper Maintenance

Dampers do not typically require maintenance as long as they are kept dry and clean. If cleaning is necessary,

use mild detergents or solvents. If lubrication is desired for components such as axle bearings, jackshaft

bearings and jamb seals, do not use oil-based lubricants or any other lubricants that attract contaminants such

as dust.

Dampers and their electric/pneumatic actuator(s) must be maintained, cycled, and tested in accordance with:

• The latest editions of NFPA 80, 90A, 92A, UL864, and local codes.

• Actuator manufacturer recommendations.

Copyright © 2006 Greenheck Fan Corporation

461868 FSDR-XXX Rev. 7 March 2006

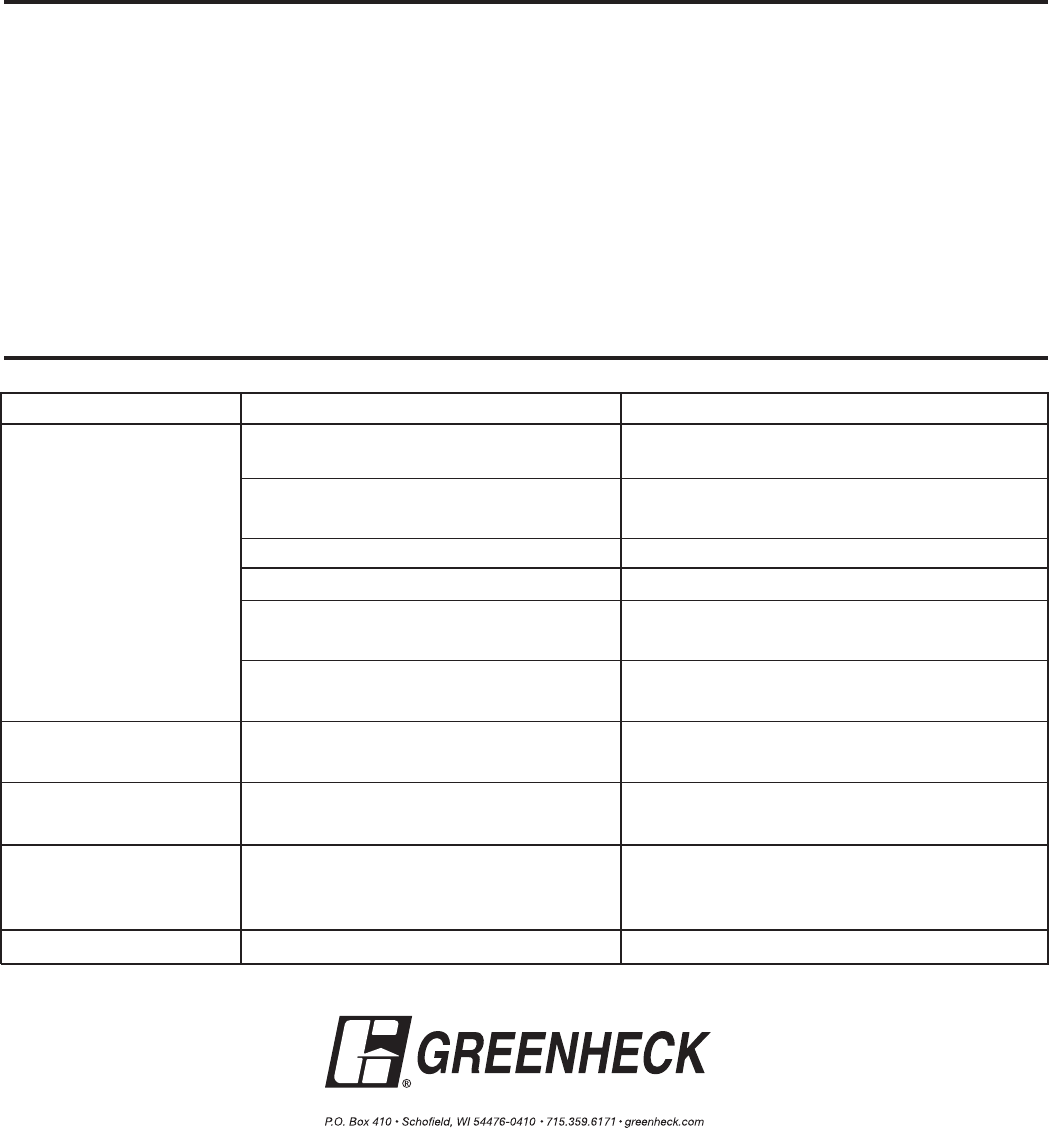

Symptom Possible Cause Corrective Action

Frame is out of round causing Adjust frame such that it is round

blades to bind on jamb seals

Actuator linkage loose Close damper, disconnect power, adjust

and tighten linkage

Defective motor Replace

Screws in damper linkage Locate screws and remove

Actuator linkage hitting wall or floor Damper installed too far into wall. Move

out to line designated on damper label.

Contaminants on damper Clean with a non-oil-based solvent

(see Damper Maintenance)

Damper does not

fully open and/or

fully close

Damper does not

operate

Actuator runs hot or

makes a humming

noise

Link separated

Heat Replace link

Actuator prohibited from reaching

end of stroke

Disconnect linkage from jackshaft,

open damper, power actuator to end of

spring, tighten linkage. Verify amp draw.

RRL, or TOR sensor

tripped

Heat

No power supplied to the actuator

Push reset button located on backside

of RRL or TOR.

Damper Trouble Shooting

The following is a possible cause and correction list for common concerns with the dampers.

Round duct connections to shall be attached with #8 sheet metal screws as follows:

• Ducts 22 in. dia. and smaller shall have three screws.

• Ducts larger than 22 in. dia. up to and including 24 in. dia. shall have five screws.

NOTE: All breakaway connections described may have duct sealant, PA2084T duct sealant adhesive manufactured by

Precision, DP1010 water base duct sealant manufactured by Design Polymetrics, or Grey Pookie applied in accordance

with SMACNA recommendations.

9. Round Duct Connections