14

EXTERNAL FILTER MAINTENANCE

Aluminum mesh 2 in. filters are located in the

supply weatherhood (if the weatherhood option

was purchased). Filters should be checked and

cleaned on a regular basis for best efficiency. The

frequency of cleaning depends upon the

cleanliness of the incoming air.

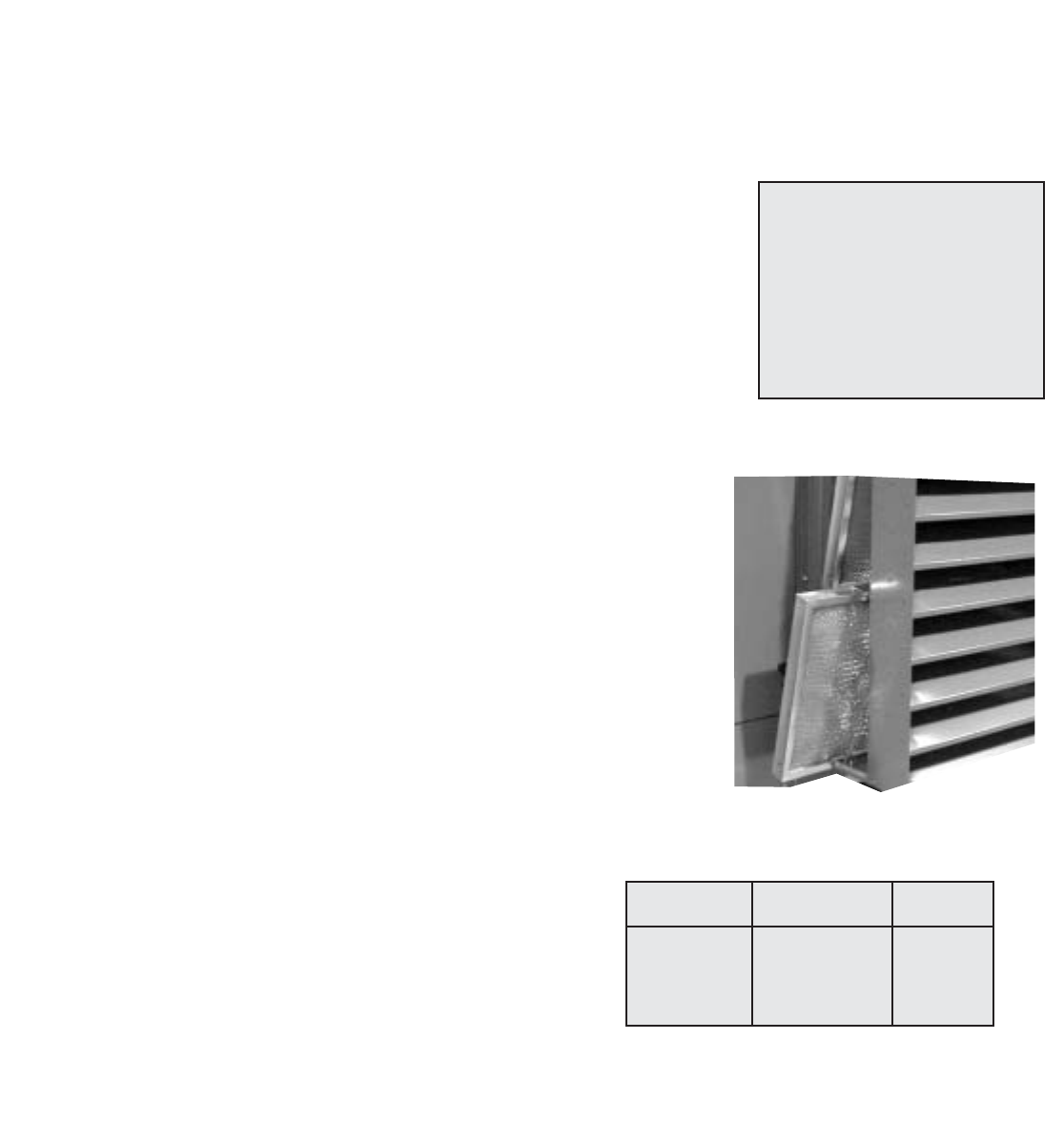

To remove these filters, remove bottom bolt in the

access door on the side of the weatherhood. Slide

the access door up and then pull out. Then, slide

the filters out (see FIGURE 19).

Clean filters by rinsing with a mild detergent in

warm water. After the filters are dry, an adhesive

spray available at most filter distributors may be

applied to increase filter efficiency.

INTERNAL FILTER MAINTENANCE

Opening the access doors labeled as “Filter

Access” provides access to the pleated 30%

filters (if the filter option was purchased). These

filters should be checked regularly, cleaned or

replaced as needed. See TABLE 7 for pleated filter

size and quantity for each unit.

FIGURE 19

Internal

Model

Filter Size

Quantity

ERH-20 20 x 20 2

ERH-45 20 x 25 3

ERH-55 16 x 25 6

ERH-90 20 x 20 8

VIBRATION

Excessive vibration maybe experienced during initial start-up. Left unchecked, excessive vibration can cause a

multitude of problems, including structural and/or component failure. The most common sources of vibration

are listed below.

Many of these conditions can be discovered by careful observation.

Refer to the troubleshooting section of this manual for corrective actions.

If observation cannot locate the source of vibration, a qualified

technician using vibration analysis equipment should be consulted. If the

problem is wheel unbalance, in-place balancing can be done providing

there is access to the fan wheel.

Generally, fan vibration and noise are transmitted to other parts of the

building by the ductwork. To eliminate this undesirable effect, the use of

heavy canvas connectors is recommended.

1. Wheel Unbalance

2. Drive Pulley Misalignment

3. Incorrect Belt Tension

4. Bearing Misalignment

5. Mechanical Looseness

6. Faulty Belts

7. Drive Component Unbalance

8. Poor Inlet/Outlet Conditions

9. Foundation Stiffness

TABLE 7