FAN FUNDAMENTAlS

130

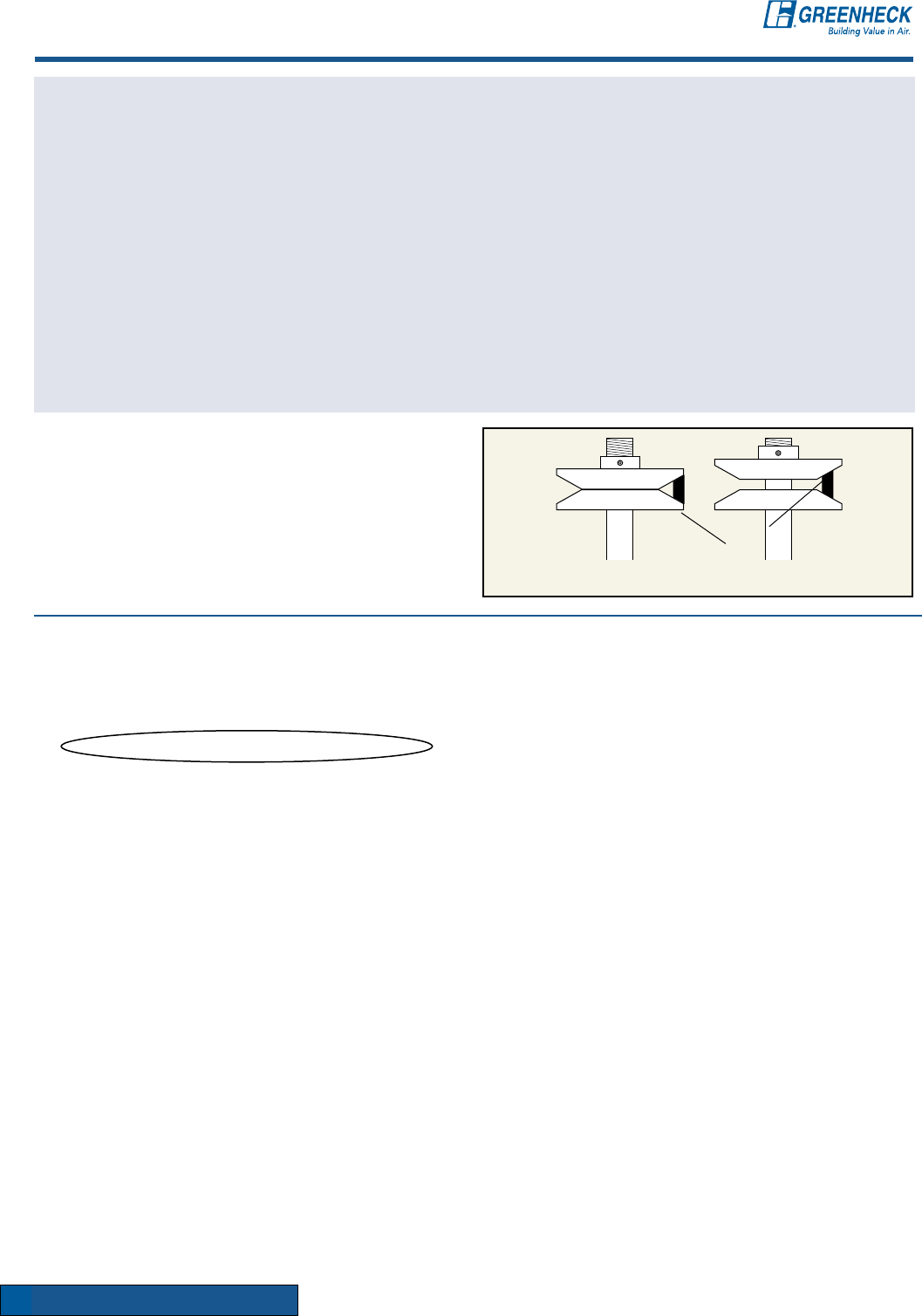

BELT DRIVE

One advantage of choosing a belt drive over a direct

drive is that it is capable of adjusting the fan rpm,

which enables the fan to move more air if necessary.

Motor pulleys are adjusted by loosening the set

screw and turning the top half of the pulley (see

illustrations at right). This causes the pulley diameter

to change, which results in changing the fan rpm.

Opening the pulley decreases fan rpm.

Closing the pulley increases fan rpm.

Belt

APPLICATIONS

Ventilating a building simply replaces stale or foul

air with clean, fresh air. Although the ventilation

process is required for many different applications,

the airflow fundamentals never change:

UNDESIRED AIR OUT, FRESH AIR IN

The key variables that do change depending on

applications are the fan model and the air volume

flow rate (cfm). Other considerations include the

resistance to airflow (static pressure or Ps) and

sound produced by the fan (Sones).

Occasionally, a customer will require a fan to perform

a particular function, yet does not know which model

to use or even what cfm is necessary. In this case,

some fan specification work must be done.

Fan specification is usually not a precise science

and can be done confidently when the fan

application is understood.

Based on the application, four parameters need to

be determined. They are:

Fan Model

Cubic Feet per Minute (cfm)

Static Pressure (Ps)

Loudness limit (sones)

MOTOR HORSEPOWER

The motor horsepower for direct drive fans is

always sized by Greenheck and does not require

further consideration. For belt drive models,

the catalog identifies which horsepower is

recommended. However, there are times when it

is wise to bump the horsepower one size. For

example, the hp recommended for the GB-180

at 810 rpm (2375 cfm @ .5” Ps) is 1/3 hp.

Although a 1/3 hp motor is recommended, it is

not necessarily a good motor selection for this

application. Our static pressure of 0.5 in. was only

an estimate. It may actually turn out to be .625 in.

If this is the case, we will need a 1/2 hp motor

because our fan will have to run at almost

810 rpm (refer to performance box - 2052 cfm at

0.625 in. Ps). Therefore, choosing a 1/2 hp motor

in this case is exercising good judgement.

The complete model designation for this

application is GB-180-5.

NOTE: The GB-180-5 has an rpm range of 700-940.

This means that if the static pressure is less than

estimated, say 0.25 in. Ps, the fan can be slowed down

to accommodate this condition.

The information that follows will help walk you

through this type of problem and enable you to

select the right fan for the job.

FAN MODEL

Fans all perform the basic function of moving air

from one space to another. But the great diversity of

fan applications creates the need for manufacturers

to develop many different models. Each model has

benefits for certain applications, providing the most

economical means of performing the air movement

function. The trick for most users is sorting through

all of the models available to find one that is

suitable for their needs.

PROPELLER vs. CENTRIFUGAL WHEEL

Propeller fans provide an economical method to

move large air volumes (5,000+ cfm) at low static

pressures (0.50 in. or less). Motors are typically

mounted in the airstream which limits applications to

relatively clean air at maximum temperatures of 110°F.

Centrifugal fans are more efficient at higher static

pressures and are quieter than propeller fans.

Many centrifugal fan models are designed with

motors mounted out of the airstream to ventilate

contaminated and high temperature air.

Introduction to FAN SELECTION