Repair

12 3A1450D

Repair

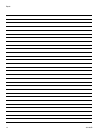

Disassembly

1. Relieve the pressure, see Pressure Relief Proce-

dure page 8.

2. Disconnect the hoses from the lower and plug the

ends to prevent fluid contamination.

3. See F

IG. 4. Remove the 2-piece shield (109) by

inserting a screwdriver straight into the slot, and

using it as a lever to release the tab. Repeat for all

tabs. Do not use the screwdriver to pry the shields

apart.

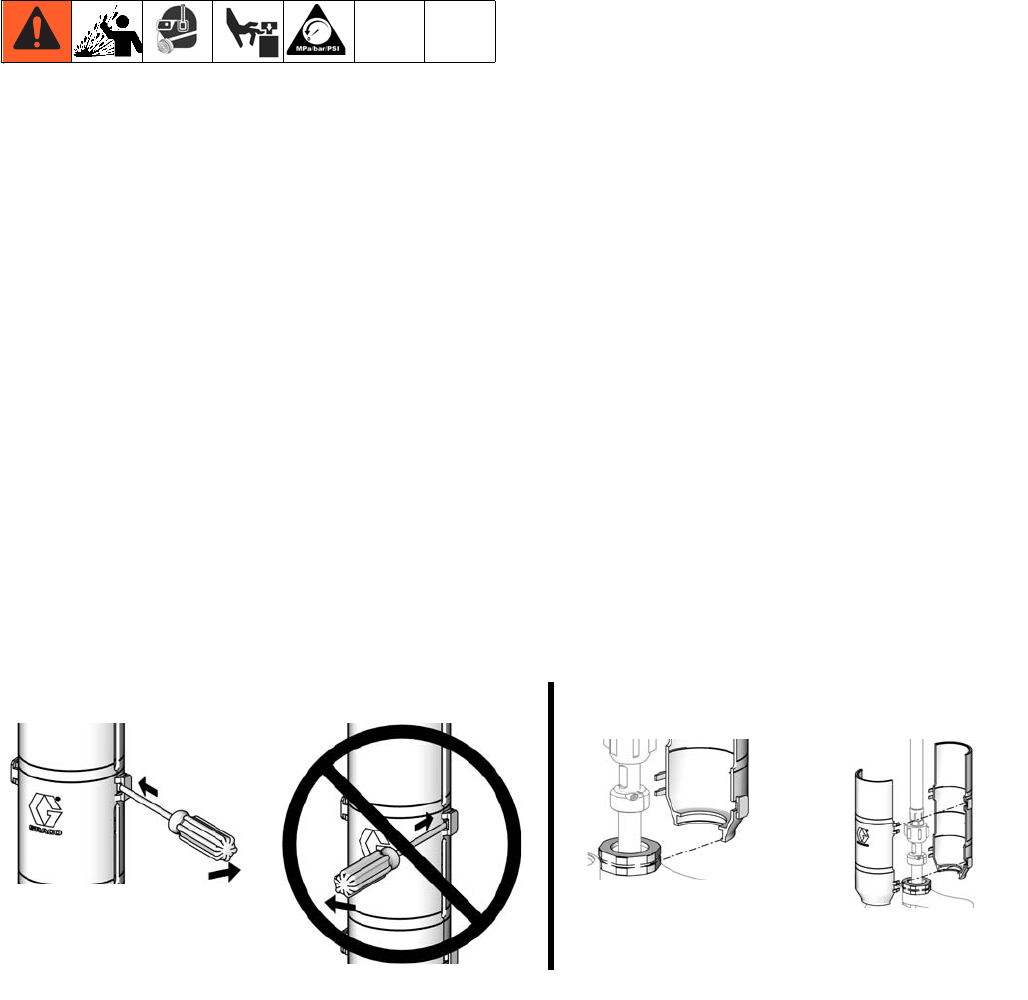

4. Loosen the coupling nut (110) and remove the col-

lars (111). Remove the coupling nut from the piston

rod (R). Unscrew the locknuts (105) from the tie

rods (104). Separate the motor (101) and lower

(102). See F

IG. 5.

5. To repair the air motor or lower, see the separate

manuals listed under Related Manuals on page 2.

Reassembly

NOTE: If the coupling adapter (108) and tie rods (104)

have been disassembled from the motor, see Reassem-

ble the Coupling Adapter and Tie Rods to the Motor

on page 13.

1. See F

IG. 5. Assemble the coupling nut (110) to the

piston rod (R).

2. Orient the lower (102) to the motor (101). Position

the lower on the tie rods (104). Lubricate the

threads of the tie rods. Screw the tie rod locknuts

(105) onto the tie rods. Tighten the locknuts and

torque to 50-55 ft-lb (68-75 N•m).

3. Insert the collars (111) into the coupling nut (110).

Tighten the coupling nut onto the coupling adapter

(108) and torque to 75-80 ft-lb (102-109 N•m).

4. See F

IG. 4. Install the shields (109) by engaging the

bottom lips with the groove in the wet-cup cap. Snap

the two shields together.

5. Flush and test the pump before reinstalling it in the

system. Connect hoses and flush the pump. While it

is pressurized, check for smooth operation and

leaks. Adjust or repair as necessary before reinstall-

ing in the system. Reconnect the pump ground wire

before operating.

FIG. 4. Disassembly and Reassembly of the Shields

ti15759a

Shield Disassembly

ti15770a

ti15757a

ti15758a

Shield Reassembly