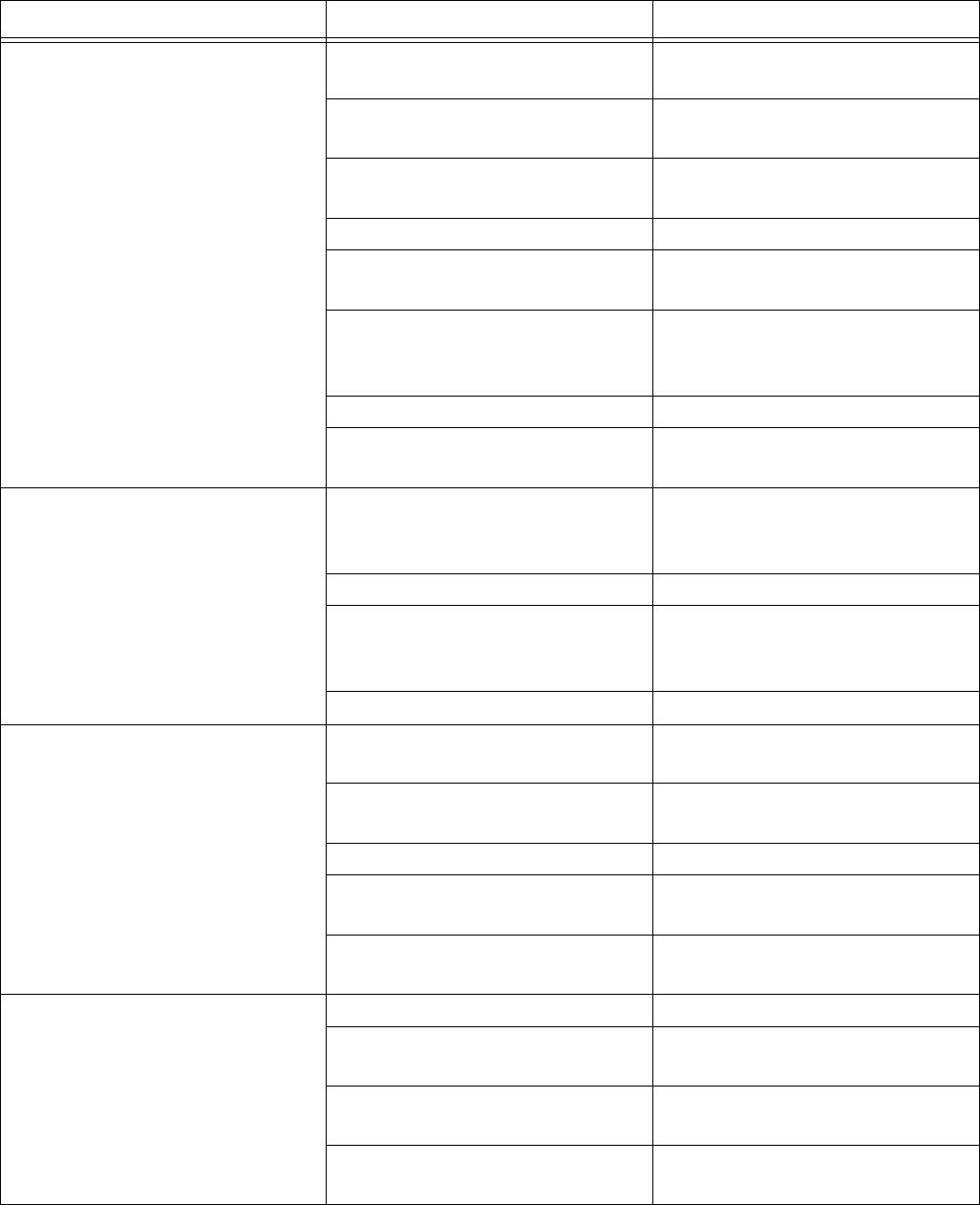

Troubleshooting

311305E 7

Unit pumps but output flow is

low.

Clogged inlet suction screen

(used oil).

Clean or replace.

Air leak in suction tube. Check to make sure all joints in

suction tube are sealed.

Suction tube too close to tank

bottom.

Suction tube must have a 2 in.

(51 mm) minimum clearance.

Tank empty. Refill tank.

Tank not vented. Tank must be vented to atmo-

sphere.

Worn or damaged gears. Remove cover and inspect

gears. Replace if worn or dam-

aged.

Damaged motor. Replace motor.

Clogged suction tube, hose, or

nozzle.

Inspect and clean.

Motor stalls when nozzle is

closed.

Bypass relief valve is stuck. Inspect relief valve, making

sure ball is free. Replace if

damaged.

Low supply voltage. Check supply voltage.

Gears damaged and binding. Inspect gears. Gears should

turn freely. Replace if dam-

aged.

Faulty motor. Replace motor.

Motor overheating. Gears binding. Check to make sure gears turn

freely on shaft.

Operating pump extended time

with nozzle closed.

Do not exceed 5 minutes of

operation with nozzle closed.

Clogged inlet suction screen. Clean or replace.

Clogged suction tube, hose, or

nozzle.

Inspect and clean if required.

Operating pump more than 30

minutes continuous duty.

Limit operation to 30 minutes

per hour.

Switch will not turn pump on. Blown fuse or circuit breaker. Check electrical supply.

Electrical problem. Check that supply voltage is

proper and getting to pump.

Defective switch. Check and replace motor (9) if

defective.

Damaged or defective motor. Check motor, replace if dam-

aged or defective.

Problem Cause Solution