8 308017

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE AND EXPLOSION

HAZARD on page 5.

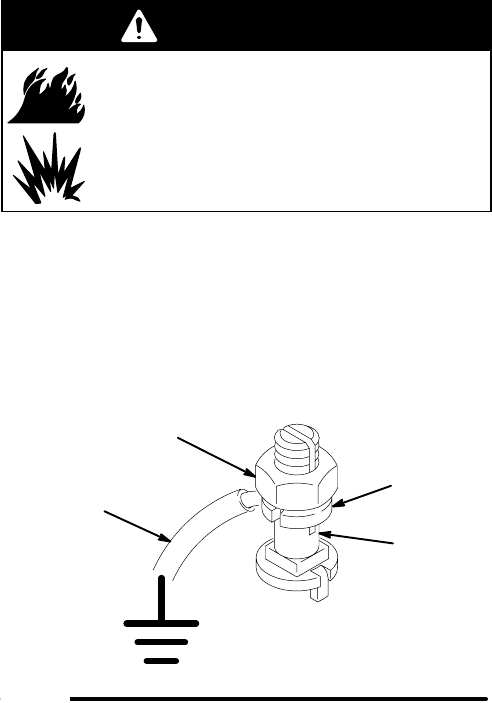

1. Pump: use a ground wire and clamp. See Fig. 2.

Loosen the grounding lug locknut (W) and washer

(X). Insert one end of a 1.5 mm@ (12 ga) minimum

ground wire (Y) into the slot in lug (Z) and tighten

the locknut securely. Connect the other end of the

wire to a true earth ground. Order Part No. 237569

Ground Wire and Clamp.

Fig. 2

W

X

Y

Z

0864

2. Air and fluid hoses: use only electrically conductive

hoses.

3. Air compressor: follow manufacturer’s recommen-

dations.

4. Spray gun/dispense valve: ground through connec-

tion to a properly grounded fluid hose and pump.

5. Fluid supply container: follow your local code.

6. Object being sprayed: follow your local code.

7. All solvent pails used when flushing: follow your

local code. Use only metal pails, which are con-

ductive, placed on a grounded surface. Do not

place the pail on a nonconductive surface, such as

paper or cardboard, which interrupts the grounding

continuity.

8. To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

gun/valve firmly to the side of a grounded metal

pail, then trigger the gun/valve.

Mounting Accessories

Mount the pump (A) to suit the type of installation

planned. Pump dimensions and the mounting hole

layout are shown on pages 46 and 47.

If you are mounting the pump on a ram (B), refer to the

manual supplied with the ram for installation and

operation instructions. The ram shown in Fig. 1 is a 19

liter (5 gal.) pail ram, used with a wiper plate (C). The

ram shown includes an air regulator (T). It also re-

quires an air supply hose (S) and an air manifold (D),

which divides the main air supply into separate lines

for the pump and the ram.

By using Pump Mounting Kit 222776, you can also

mount the pump on Floor Stand 222780, 200 liter (55

gal.) Ram 207279, or Inductor 222635.