308017 19

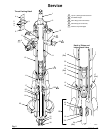

Service

Reassembly (Refer to Fig. 8)

1. Place a 13 mm (1/2 in.) diameter brass rod length-

wise in a vise. Install a new piston seal (15*) on

the piston seat. Apply thread sealant to the

threads of the piston seat. Place the piston guide

(14) securely on the brass rod. Using a 32 mm

crow’s-foot, screw the piston seat (16) into the

piston guide. Torque to 27–34 N.m (20–25 ft-lb).

2. If it was necessary to remove the priming piston

rod (24) from the piston (13), apply thread sealant

to the threads of the rod. Place the flats of the

piston (13) in a vise. Hold the flats of the rod with a

12 mm wrench, and screw the rod into the piston.

Torque to 45–53 N.m (33–39 ft-lb).

3. Use a vise with soft jaws to hold the displacement

rod (1) by its flats. Install the spacer (33, see the

following note) on the rod. Install the assembled

piston guide/seat on the piston (13). Apply thread

sealant to the threads of the displacement rod, and

screw the piston assembly onto the rod, using a 19

mm wrench on the flats of the piston. Torque to

120–130 N.m (88–95 ft-lb). There will be a small

gap between the top of the piston (13) and the

shoulder of the rod (1).

NOTE: The piston spacer (33) is not required when

pumping fluids with a viscosity greater than 1 million

centipoise.

4. Lubricate the threads of the bleeder valve plug

(35). The plug has two sets of threads. Be sure to

screw the plug completely into the valve body (43).

Torque the plug to 30–38

NSm (22–28 ft-lb).

NOTE: Some models include an outlet nipple (8) and

o-ring (9*). It is not ordinarily necessary to remove

these parts. However, if they were replaced because of

damage, lubricate the o-ring and place it on the nipple.

Screw the nipple into the outlet housing (10). Torque to

70–75 N.m (51–55 ft-lb).

5. Lubricate the o-rings (11*) and install them on the

cylinder (12). Apply thread lubricant to the top

threads of the cylinder. Using a 400 mm wrench on

the flats of the cylinder, screw it into the outlet

housing (10). Torque to 325–354 N.m (240–260

ft-lb).