308441 5

Installation

General Information

D The typical installation shown in Fig. 2 is only a

guide for selecting and installing system compo-

nents. Contact your Graco distributor for assistance

in planning a system to suit your needs.

D Always use Genuine Graco Parts and Accessories.

Refer to Product Data Sheet 305646.

D Reference numbers and letters in parentheses refer

to the callouts in the figures and the parts lists on

pages 25–24.

D Lift the pump by grasping the outlet manifold (1)

securely. See Fig. 3 on page 8.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

1. Read TOXIC FLUID HAZARD on page 4.

2. Use fluids and solvents which are compatible

with the equipment wetted parts. Refer to the

Technical Data section of all equipment manu-

als. Read the fluid and solvent manufacturer’s

warnings.

WARNING

Tightening Screws Before First Use

Before using the pump for the first time, check and

retorque all external fasteners. See Torque Se-

quence, page 28. After the first day of operation,

retorque the fasteners. Although pump use varies, a

general guideline is to retorque fasteners every two

months.

Grounding

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before

operating the pump, ground the system

as explained below. Also, read the sec-

tion FIRE AND EXPLOSION HAZARD,

on page 4.

WARNING

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equip-

ment. Ground all of this equipment:

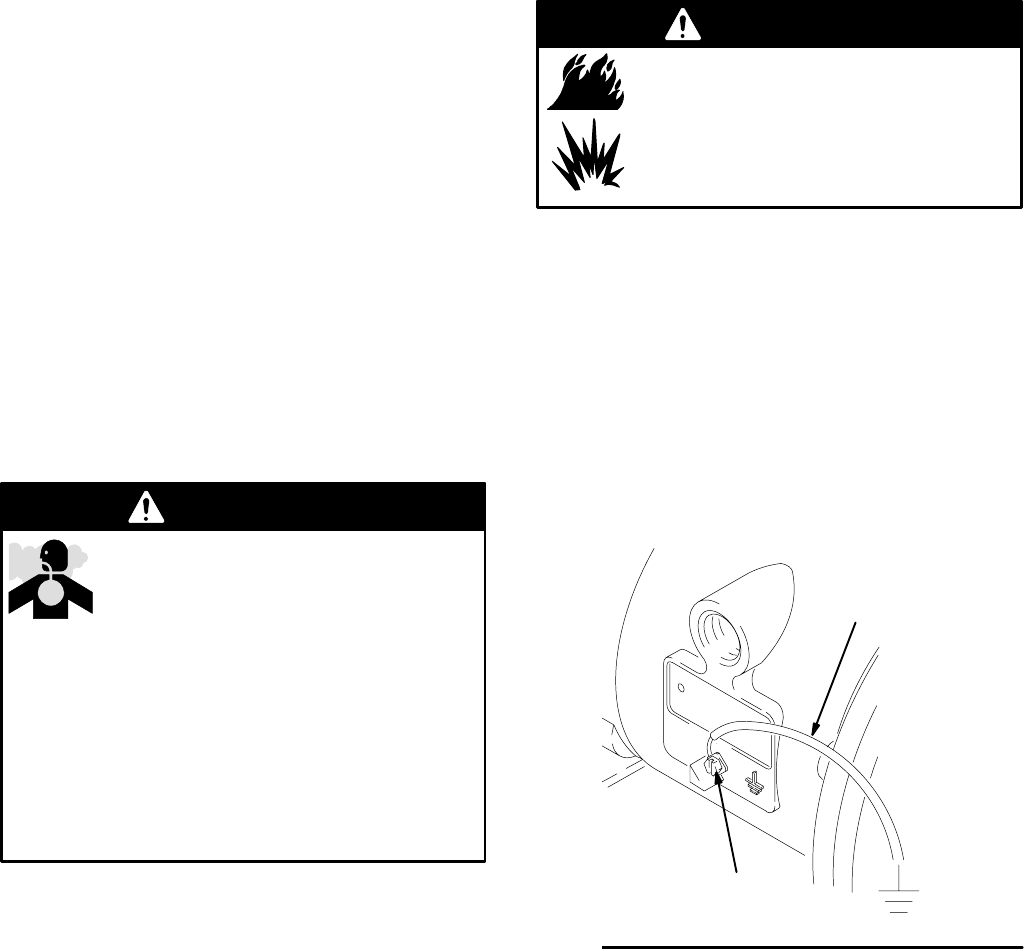

D Pump: Connect a ground wire and clamp as shown

in Fig. 1. Loosen the grounding screw (W). Insert

one end of a 12 ga (1.5 mm@) minimum ground wire

(Y) behind the grounding screw and tighten the

screw securely. Connect the clamp end of the

ground wire to a true earth ground. Order Part

No. 222011 Ground Wire and Clamp.

Fig. 1

Y

W

02646B

D Air and fluid hoses: Use only grounded hoses with

a maximum of 500 ft (150 m) combined hose

length to ensure grounding continuity.

D Air compressor: Follow the manufacturer’s recom-

mendations.

D All solvent pails used when flushing: Follow the

local code. Use only metal pails, which are conduc-

tive. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which inter-

rupts the grounding continuity.

D Fluid supply container: Follow the local code.