Repair

308391J 13

14. Align the tie rods (47) and bolts (23) and torque to

70 to 80 ft-lbs (95 to 108 N.m). Install eyelet (26)

Attach hoist to the eyelet.

15. Screw the top and bottom flare nuts on the hydraulic

tube (49), and install the tube.

16. Place the motor horizontally in a vise at the pump

adapter (42) and the bottom cylinder cap (43).

17. Apply thread sealant to the threads of the piston

(110) and install the piston, ball (103), and the seal

(107) with the lips facing up.

18. Remove the hydraulic motor from the vise.

19. Place the piston (110) flats in a vise.

20. Tighten the piston rod (44) with a wrench.

21. Remove the piston from the vise.

22. Place the pump horizontally in the vise.

23. Install the displacement pump with a strap wrench.

24. Remove the hydraulic motor from the bench vise.

25. Unplug all hydraulic connections and lines and con-

nect the hydraulic hoses. Connect the displacement

pump hoses.

26. Flush the displacement pump if possible. Relieve

the pressure (page 8)

Intake Valve

Refer to FIG. 5 for the following instructions.

1. Relieve the pressure, see page 8.

2. Unscrew the valve body (112). Remove the o-ring

(105), ball (104), and retainer (113).

3. Inspect the parts for wear or damage. If the ball is

nicked, replace it. Reassemble, using grease on the

male threads.

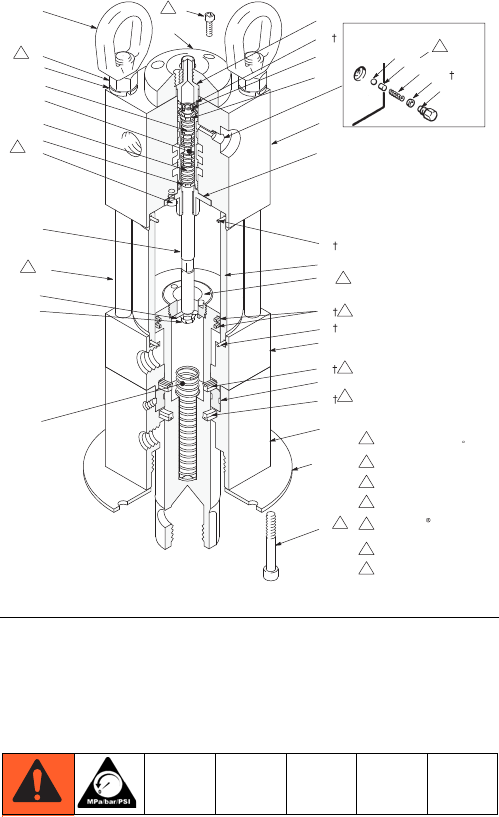

FIG. 4

26

5

22

33

18

16

41

50

12

15

12

17

42

47

25

Lips must face

up toward top of motor

Rings must be positioned

with joints opposed 180

38

31

30

7

41

Apply Loctite TL–242

thread sealant to threads

43

Torque to

70–80 ft–lb (95–108 N.m)

1

4

5

2

1

2

6

4

6

Concave surface faces ball

6

37

10

34

34 36

9

7

7

Torque to

120–130 ft–lb (163–176 N.m)

17

3

Lips must face down to-

ward bottom of pump

3

4

5

29

21

46

32

40

11

39

5

35

45

5