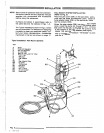

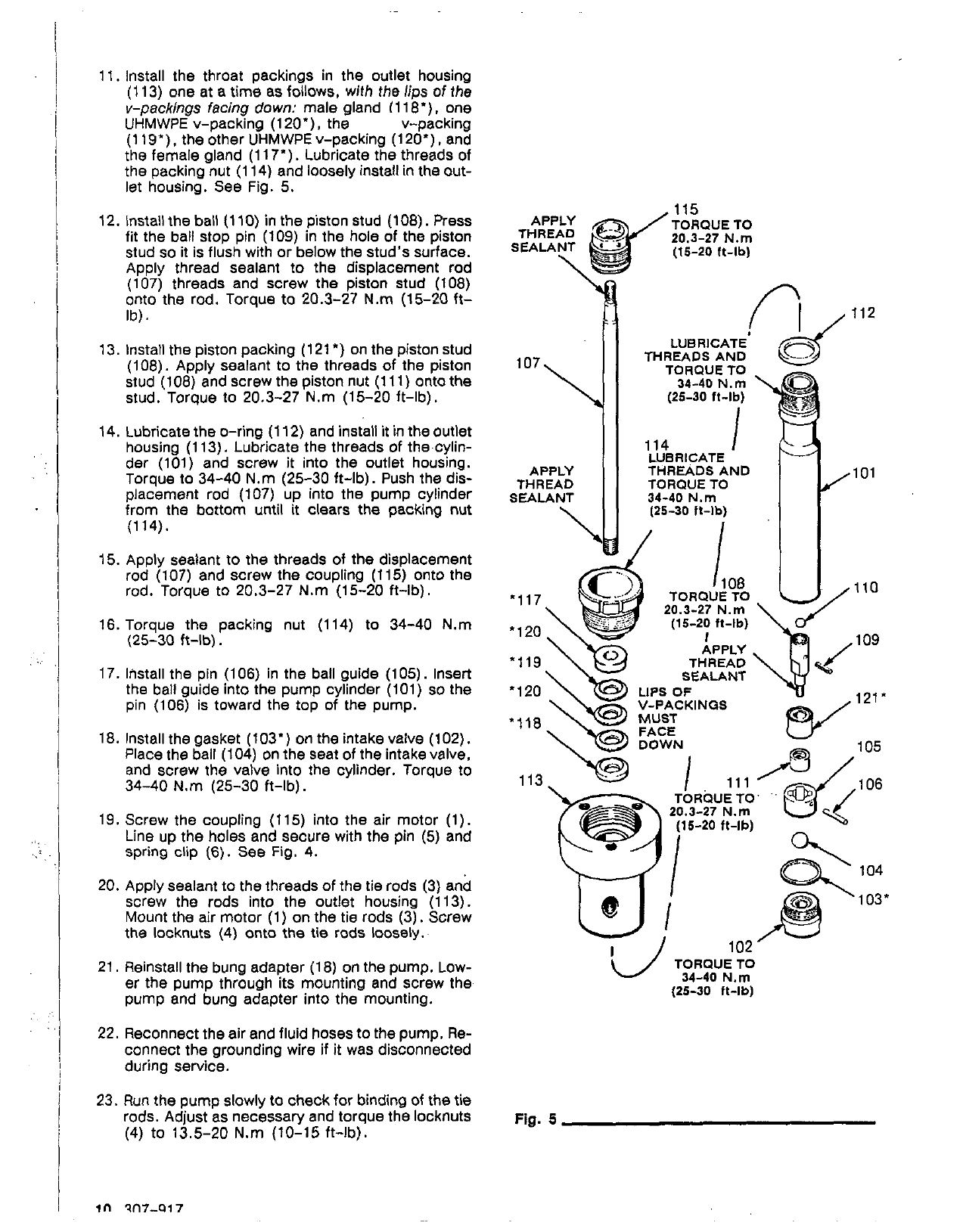

11. Install the throat packings in the outlet hOUSing

v-packings facing

down:

male gland (1

l8'),

one

(1 13) one at a

time

as follows,

with the

lips

of

the

UHMWPE v-packing (120'), the v-packing

the female gland (1 17'). Lubricate the threads of

(1 19"). the other UHMWPE v-packing (120'), and

the packing nut (1 14) and

loosely

install

in

the out-

let housing.

See

Fig. 5.

12. Install the ball (1 10) in the piston stud (108). Press

fit the ball stop pin (109) in the hole of the piston

stud

so

it is flush with or below the stud's surface.

Apply thread sealant to the displacement rod

(107) threads and screw the piston stud (108)

onto the rod. Torque to 20.3-27

N.m

(15-20 ft-

Ib).

13. Install the piston packing (1 21 *) on the piston stud

(108). Apply sealant to the threads

of

the piston

stud (108) and screw the piston nut (111) ontothe

stud. Torque to 20.3-27

N.m

(15-20 ft-lb).

14. Lubricate the O-ring (1 12) and install it in the outlet

der (101) and screw it into the outlet housing.

housing (1 13). Lubricate the threads

of

the.cylin-

Torque to 34-40

N.m

(25-30 ft-lb). Push the dis-

placement rod (107) up into the pump cylinder

from the bottom until

it

clears the packing nut

(114).

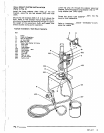

15. Apply sealant to the threads of the displacement

rod (107) and screw the coupling (115) onto the

rod. Torque to 20.3-27

N.m

(15-20 ft-lb).

16. Torque the packing nut (114) to 34-40

N.m

(25-30

ft-lb).

17. Install the pin (106) in the ball guide (105). Insert

the ball guide into the pump cylinder (101)

so

the

pin (106) is toward the top of the pump.

18. Install thegasket (103') on the intake valve

(102).

Place the ball (104) on the seat

of

the intakevalve,

and screw the valve into the cylinder. Torque to

34-40

N.m

(25-30 ft-lb).

19.

Screw the coupling (115) into the air motor (1).

Line up the holes and secure with the pin

(5)

and

spring clip (6).

See

Fig. 4.

20. Apply sealant to the threads of the tie rods (3) and

screw the rods into the outlet housing (1 13).

the locknuts

(4)

onto the tie rods loosely.

Mount the air motor (1) on the tie rods (3). Screw

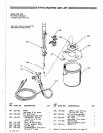

21. Reinstall the bung adapter (1

8)

on the pump. Low-

er the pump through its mounting and screw the

pump and bung adapter into the mounting.

22.

Reconnect the air and fluid hoses to the pump.

Re-

connect the QrOtJnding wire if it was disconnected

during service.

23. Run the pump slowly to check for binding of the

tie

rods. Adjust as necessary and torque the locknuts

(4)

to 13.5-20

N.m

(10-15 ft-lb).

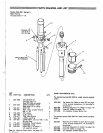

APPLY

THREAD

SEALANT

115

TORQUE

TO

20.3-27

N.m

(15-20

It-lb)

,101

,110

i/

TORQUE

TO

34-40

N.m

(25-30

ft-lb)

Fig.

5

PTFE