8 307674

Operation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying acci-

dentally. To reduce the risk of an injury from acci-

dental spray from the gun, splashing fluid, or

moving parts, follow the Pressure Relief Proce-

dure whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray nozzle.

1. Shut off the air supply to the pump.

2. Close the bleed-type master air valve (A, required

in your system).

3. Hold a metal part of the gun firmly to the side of a

grounded metal pail, and trigger the gun to relieve

pressure.

4. Open the drain valve (D, required in your system),

having a container ready to catch the drainage.

5. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray nozzle or hose is com-

pletely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the nozzle retaining ring or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the nozzle or hose.

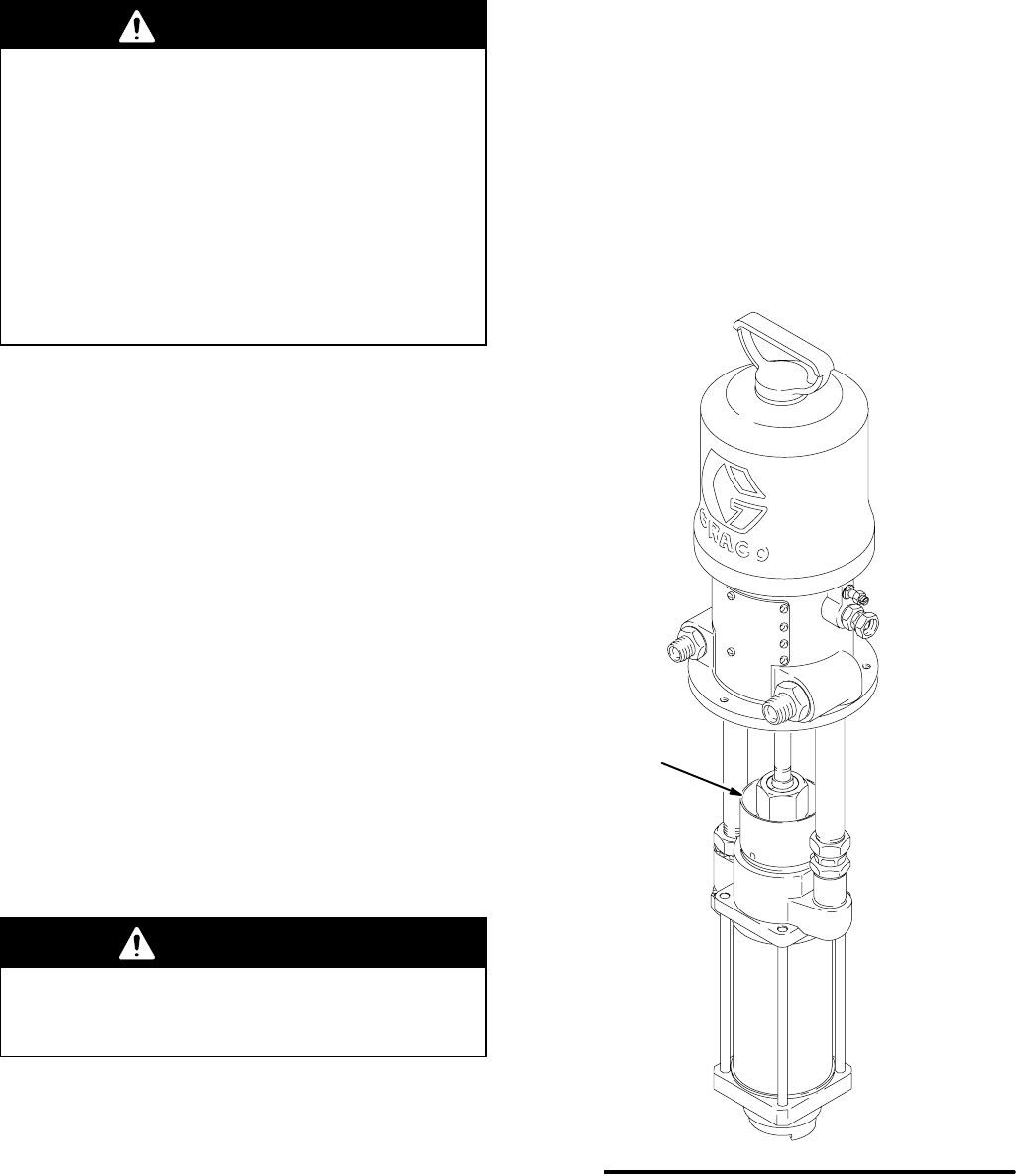

Packing Nut

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure at left.

Check the tightness of the packing nut/wet-cup (U)

periodically. The nut should be tight enough to prevent

leakage. Torque the nut to 20–24 ft-lb (27–33 N.m); do

not overtighten or you may damage the packings.

Relieve pressure before adjusting the nut. See Fig. 3.

If the pump is not immersed, fill the packing nut/wet-

cup 1/2 full with a compatible solvent. Keep the cup

filled at all times to help prevent the fluid you are

pumping from drying on the exposed displacement rod

and damaging the throat packings.

Flush the Pump Before First Use

The pump is tested with lightweight oil, which is left in

to protect the pump parts. If the fluid you are using

may be contaminated by the oil, flush it out with a

compatible solvent. See Flushing on page 10.

06110

Fig. 3

U

Model 218747 Shown