Installation

306642F 3

Installation

Grounding

In a low pressure air spray system, static sparking is

generally not a problem; however some simple precau-

tions should be taken to reduce the risk. Check your

local code for detailed grounding instructions for your

area and type of equipment. Ground all equipment.

Grounding reduces the risk of static and electric shock

by providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

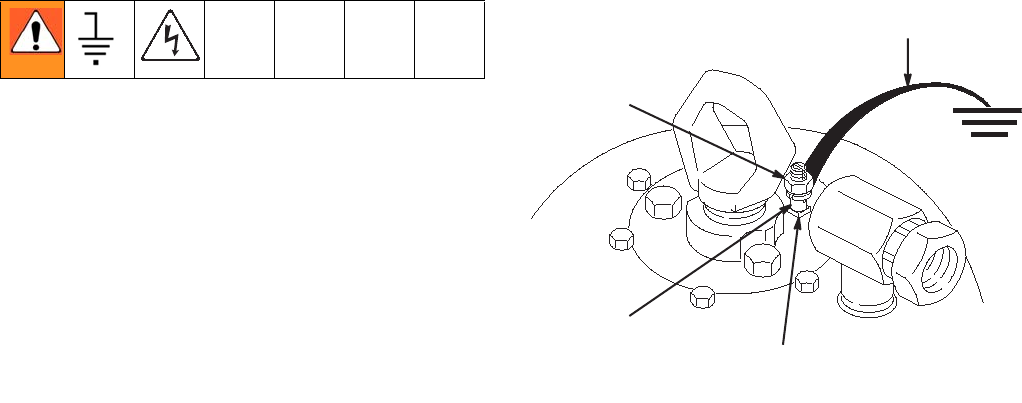

• Pump: (F

IG. 1) Use ground wire and clamp (sup-

plied). Loosen grounding lug locknut (a) and washer

(b). Insert one end of ground wire (c) into the slot in

the lug (d). Tighten locknut securely. Connect other

end of wire to a true earth ground.

F

IG. 1

• Air Compressor: according to manufacturer’s rec-

ommendations.

• Object being sprayed: according to local code.

• Fluid supply container: according to local code.

• All solvent pails used when flushing: according to

local code.

Only use conductive, metal pails. Do not place the

pail on a non-conductive surface such as paper or

cardboard, which interrupts the grounding continu-

ity.

• To maintain grounding continuity when flushing or

relieving pressure, always hold metal part of the dis-

penser firmly to the side of a grounded metal pail,

then squeeze trigger.

(a)

(b)

(d)

(c)