8

LP301A-5100 REPAIR INSTRUCTIONS

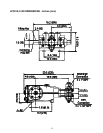

12) Check plunger surface (29B). If plunger pipe is worn out,

loosen tension screws (29C) with a 15mm socket and pull off

plunger pipe to the front. Clean front surface of plunger (29B)

thoroughly. Apply a small drop of locktite to tension screw. Put

a new crush washer (29D) onto tension screw. Put a thin coat

of glue (Loctite) on the ring (or ceramic plunger side) and

tighten screw to 265 in.-lbs.

29B 29D 29C

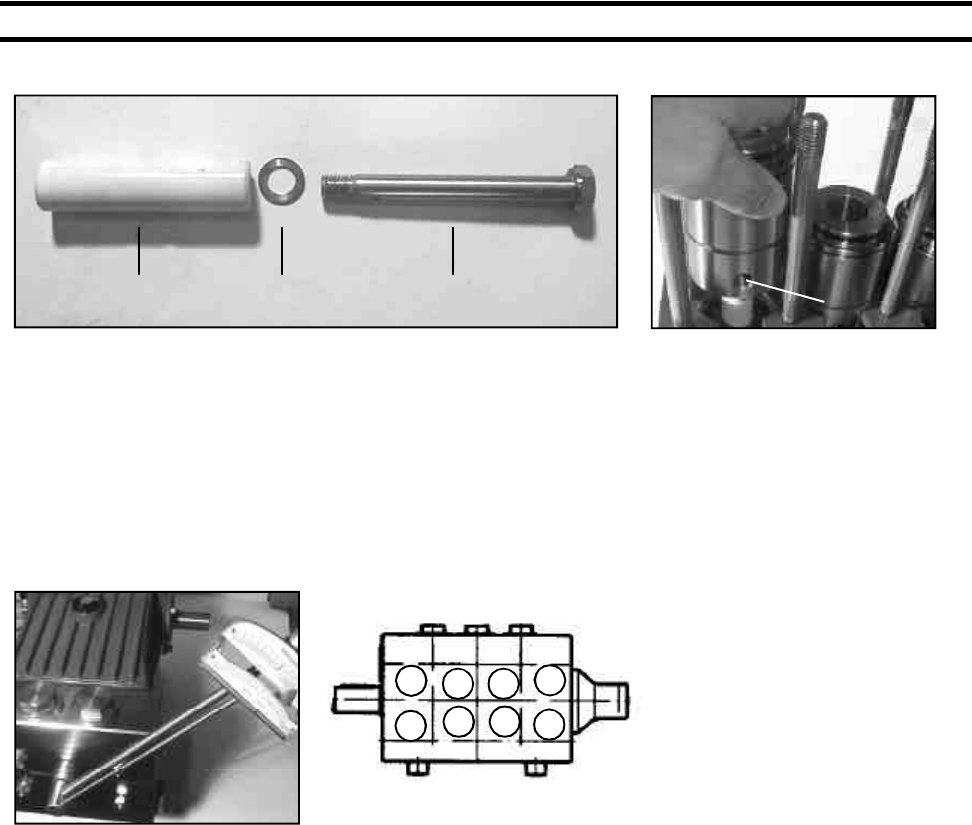

13) Replace complete seal sleeve

(35)/seal case (37) assembly

into crankcase (1). Make

sure that the weep hole

points downward. Note: To

replace the oil seals (31),

you will need to disas-

semble the gear end (see

instructions below).

Weep Hole

14) Place entire manifold/seal

sleeve assembly over the

studs and push firmly until

seated against the crankcase.

15) Tighten hex nuts (49A) in a

crosswise pattern (shown

above) to 59 ft.-lbs.

6

4 2

7

8

1 3

5