6

1) Loosen and remove tension

plugs (48) with a 36mm

socket wrench.

TO CHECK VALVES

NOTE: Always take time to lubricate all metal and non-metal parts with a light film of oil before reassembling. This step

will help ensure proper fit, at the same time protecting the pump non-metal parts (elastomers) from cutting and scoring.

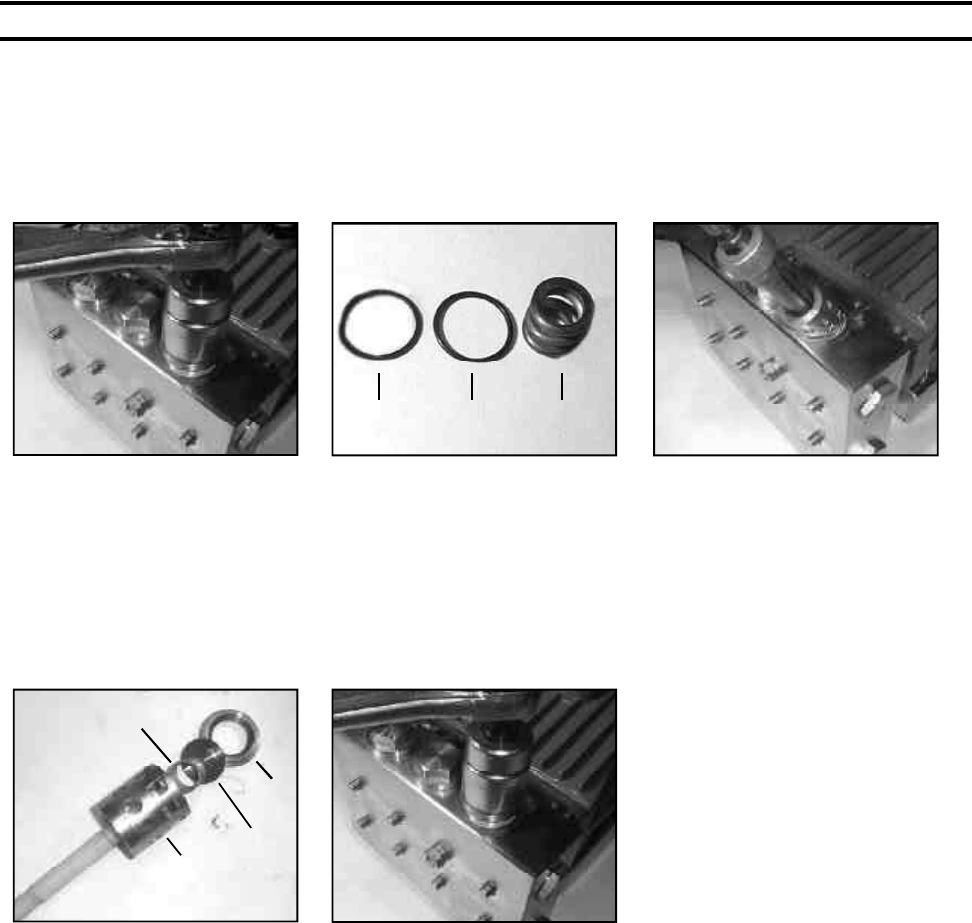

44B 44A 45

2) Remove the support ring

(44B), o-ring (44A) and ten-

sion spring (45).

3) Take out discharge valve as-

semblies (46) by pulling

them upwards out of the

valve casing (43) with a

snap-ring tongs or any other

pull-off device. Then re-

move inlet valves in the

same way.

4) Loosen valve seats (46A)

and valve spring (46C)

from spacer pipe (46D) by

lightly hitting the valve

plate (46B) with a plastic

stick. Check sealing surface

and replace worn parts.

Reassemble with new o-

rings (44A) if possible and

oil them before installing.

5) Tighten up tension plugs

(48) to 107 ft.-lbs.

46A

46D

46B

LP301A-5100 REPAIR INSTRUCTIONS

46C