8

38

8. Remove seal case (37) from

valve casing (43) and inspect

o-ring (38).

9. Check plunger surface (29B). If plunger pipe is worn out, loosen

tension screws (29C) and pull off plunger pipe to the front. Clean

front surface of plunger (25) thoroughly. Apply a thin coat of

Loctite to the tension screw threads (29C). Note: Care must be

taken that no glue gets between the plunger pipe (29B) and

the centering sleeve (29A). Add new copper ring (29D).

29B 29D 29C

10. Place new plunger pipe

(29B) carefully through the

oiled seals and push seal

sleeve (35) with plunger

pipe into the crankcase

guide. Note: Make sure

weep hole is facing down.

11. Tighten the tension screws

(29C) to 310 in.-lbs. The

plunger pipe (29B) should

not be strained by over

tightening of the tension

screw (29C) or through

damage to the front surface

of the plunger; otherwise, it

will probably break.

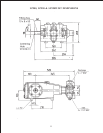

12. Place valve vasing (43)

over studs and push firmly

until seated against the

crankcase (1). Tighten the

hexagon nuts (49A) in a

crosswise pattern (shown

below) to 59 ft.-lbs.

4

1

2

3

6

8

7

5

LP200, LP250 & LP250W-MT - REPAIR INSTRUCTIONS