11

920-198-00

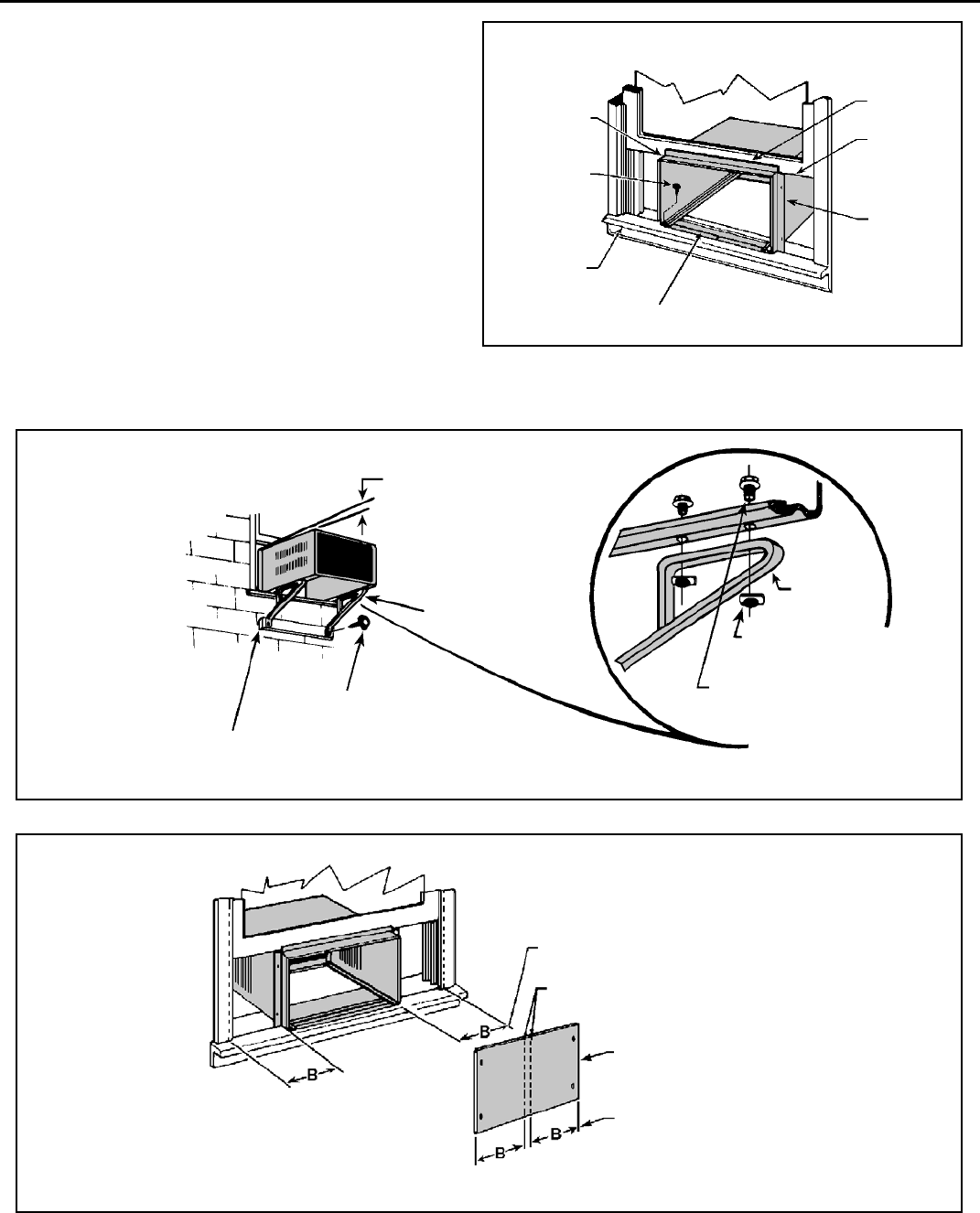

Figure D

⅜" DOWN SLOPE

SUPPORT BRACK ET

(ITEM #1)

#12A x 2" SCREW

(ITEM #4)

1" x 4" OR 2" x 4" SPACER SHOULD BE USED

BE TWEEN WALL AND BRACKET WHEN IN STALLED

ON ALUMINUM, ASBESTOS OR VINYL SIDING

SUPPORT

BRACKET

10 – 24 FLAT WELD

NUT (ITEM #3)

10 – 24 x 1" HEX HD.

SCREW (ITEM #2)

STEP 8 OUTSIDE SUPPORT MOUNTING – Assemble the support

brackets (Item #1) to the bottom rails of the cab i net with four

(4) 10-24 1" long screws (Item #2) and four (4) 10-24 fl at nuts

(Item #3). Adjust the support brackets to bring the bottom pads

in contact with the wall surface. (A 1" x 4" or 2" x 4" SPACER

SHOULD BE USED BETWEEN THE WALL AND THE

SUPPORT BRACKETS WHEN IN STALLED ON ALU MI NUM

OR VINYL SIDING). Drill

5

⁄

32

" dia. pilot holes and secure the

brack ets to the wall with two (2) #12A x 2" long screws (Item

#4). Adjust the support brackets to provide an ap prox i mate 3/8"

down slope toward the out side for drainage. (See Figure D).

Tighten all screws.

NOTE: The discharge air, return air, condenser air inlets and

outlets must be unobstructed to avoid recirculation of rejected

heated air.

The following illustrations show a standard frame con struc tion installation as well as some suggested ways of adapt ing the support bracket to thick walls and

large stone ledges.

CENTER

CABINET IN

WINDOW SIDE

TO SIDE.

DRILL (3)

5

⁄

32

"

PILOT HOLES

AND INSTALL

(3) #12A x

2" LONG

SCREWS

(ITEM #4)

WINDOW

SILL

LOCATE SILL PLATE GUIDE CHAN NEL

JUST BACK OF WIN DOW SILL

TOP

SUPPORT

ANGLE

PULL

WINDOW

SASH DOWN

BEHIND TOP

SUPPORT

ANGLE

SIDE

SUPPORT

ANGLE

Figure C

Figure E

MEASURE DISTANCE "B" TO INSIDE OF THE

CHANNEL ON EACH SIDE

CUT HERE AND DISCARD CENTER WASTE

MATERIAL.

WINGBOARD

SUBTRACT ⅛" FROM DIMENSION "B" AND

MEA SURE FROM THE EDGE OF THE WING-

BOARD (ITEM # 8), MARK, SCORE AND CUT

WITH APPROPPRIATE CUTTING TOOL

NOTE: It is not necessary to cut the wingboard for

vertical height; only horizontal WIDTH Dimension “B”.