5

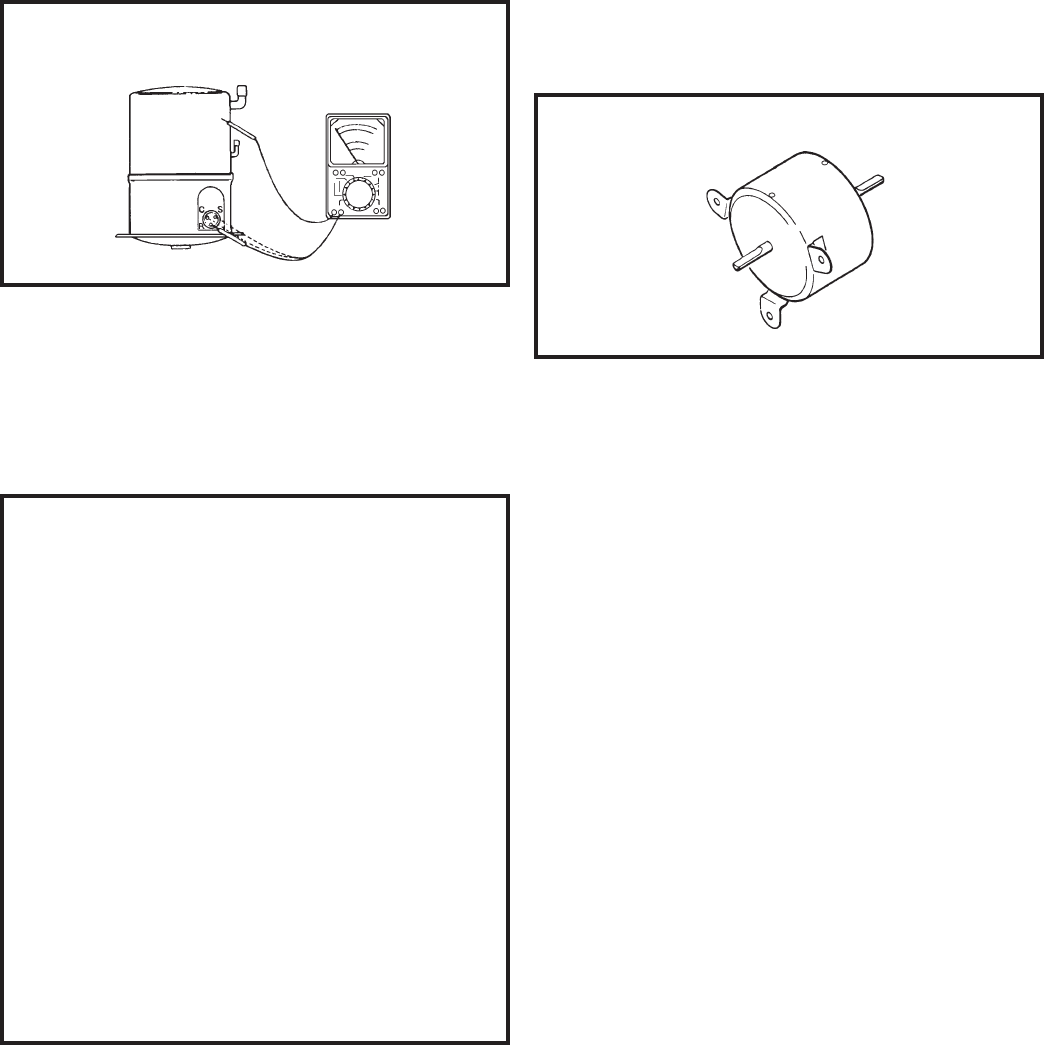

FAN MOTOR (Figure 4)

A 230 volt single phase permanent split capacitor

motor is used to drive the evaporator blower and

condenser fan. A running capacitor is wired

across the start and run terminals of the motor.

The motor is totally enclosed and is protected with

a line voltage overload located internally of the

motor. The motor shaft is stainless steel to resist

corrosion.

CHECKING COMPRESSOR EFFICIENCY

The reason for compressor inefficiency is

normally due to broken or damaged suction

and/or discharge valves, reducing the ability of

the compressor to pump refrigerant gas.

This condition can be checked as

follows:

1. Install a piercing valve on the suction and

discharge or liquid process tube.

2. Attach gages to the high and low sides of the

system.

3. Start the system and run a "cooling or

heating performance test."

If test shows:

A. Below normal high side pressure.

B. Above normal low side pressure.

C. Low temperature difference across the coil.

The compressor valves are faulty -

replace the compressor.

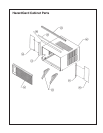

GROUND TEST

Use an ohmmeter set on its highest scale. Touch

one lead to the compressor body (clean point of

contact, as a good connection is a must) and the

other probe in turn to each compressor terminal.

(See Figure 3.) If a reading is obtained, the

compressor is grounded and must be replaced.

FIGURE 3 TYPICAL GROUND TEST

FAN MOTOR – TEST

Disconnect power to the unit.

1. Determine that the capacitor is serviceable.

2. Disconnect the black lead from the circuit

board.

3. Apply "live" test cord leads to the common

terminal of the capacitor and the black lead.

The motor should run at high speed.

FIGURE 4 FAN MOTOR