4

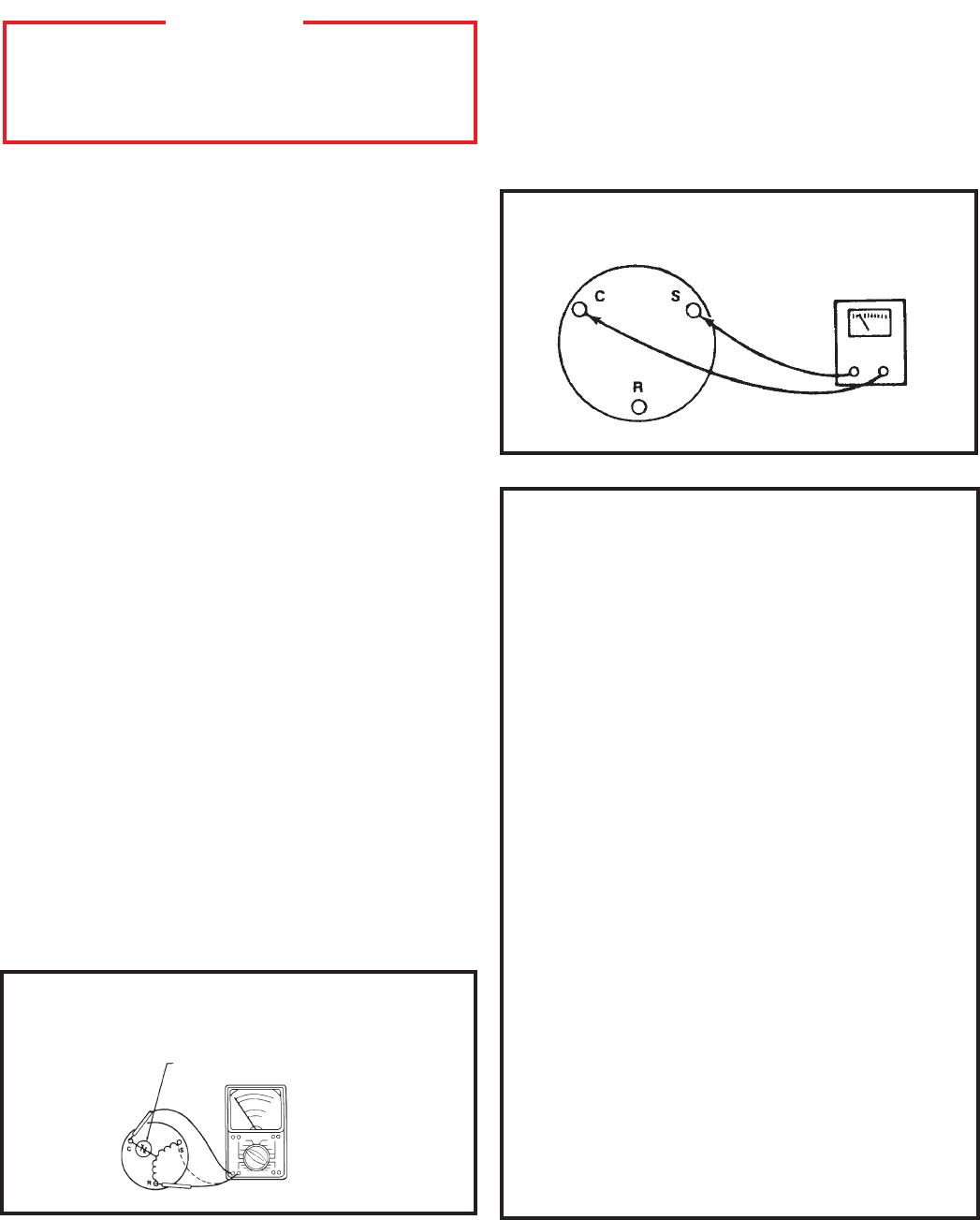

COMPRESSOR WINDING TEST

(See Figure 2.)

Remove the compressor terminal box cover and

disconnect the wires from the terminals. Using

an ohmmeter, check continuity across the

following:

DISCONNECT ELECTRICAL POWER TO

THE UNIT BEFORE SERVICING OR

TESTING

COMPONENT OPERATION AND TESTING

WARNING

COMPRESSORS

Compressors are single phase, 208/230 volt. All

compressor motors are permanent split capacitor

type, using only a running capacitor across the

start and run terminal.

All compressors are internally spring mounted and

externally mounted on rubber isolators.

Line Voltage Overload

The compressor is equipped with an internal line

voltage overload. This overload is embedded in

the windings of the motor to sense the motor

temperature. The overload will open and

disconnect the power to the motor due to high

temperatures caused by:

1. A locked rotor.

2. Excessive running amps.

3. High discharge temperature.

4. Low refrigerant charge.

FIGURE 1 INTERNAL OVERLOAD

LINE BREAK

INTERNAL OVERLOAD

OHMMETER

FIGURE 2 COMPRESSOR WINDING TEST

Testing Procedures

1. Terminal "C" and "S" - no continuity -

open winding - replace compressor.

2. Terminal "C" and "R" - no continuity -

open winding - replace compressor.

3. Terminal "R" and "S" - no continuity

open winding - replace compressor.

4. Terminal "C" and the shell of the

compressor – continuity – grounded

motor – replace compressor.

5. Should continuity exist between

terminals "R" and "S", but not between

terminals "C" and "S" and "C" and "R",

the internal overload may be open. If

the compressor is extremely hot, allow

it sufficient time to cool. It may require

as long as one hour for the compressor

to cool sufficiently for the internal

overload to close.