2

8. Make sure the shaft is clean.

9. Clean the face of the rotating part of the seal with a

soft cloth. Dip the assembly in a soap solution or clear

water and push onto the shaft, with the sealing face

fi rst, until the square rubber drive ring is completely on

the shaft shoulder.

10. Screw the impeller on the shaft until its hub is against

the shaft shoulder. This automatically positions all

seal parts properly.

11. Replace the motor on the case and base.

TROUBLESHOOTING

1. PUMP WON’T DELIVER ANY WATER

Review priming instructions. Make sure the pump and

suction line are full of water.

2. LOSS OF PRIME

a) Check the suction line and foot valve for leaks. The

entire suction side of the system must be totally

air tight.

b) Make sure the water level hasn’t dropped enough

to uncover the suction inlet. Suffi cient pipe would

be used to prevent this from happening.

3. LOW FLOW OR PRESSURE

a) Check suction piping for leaks.

b) Check the impeller for clogging. Remove all foreign

material if it is clogged.

4. NOISE

a) Make sure pump and piping are supported.

b) Make sure suction lift does not exceed 20 ft.(6mm)

c) Check disch. piping for excessive bends or elbows.

d) Check motor bearing for damage.

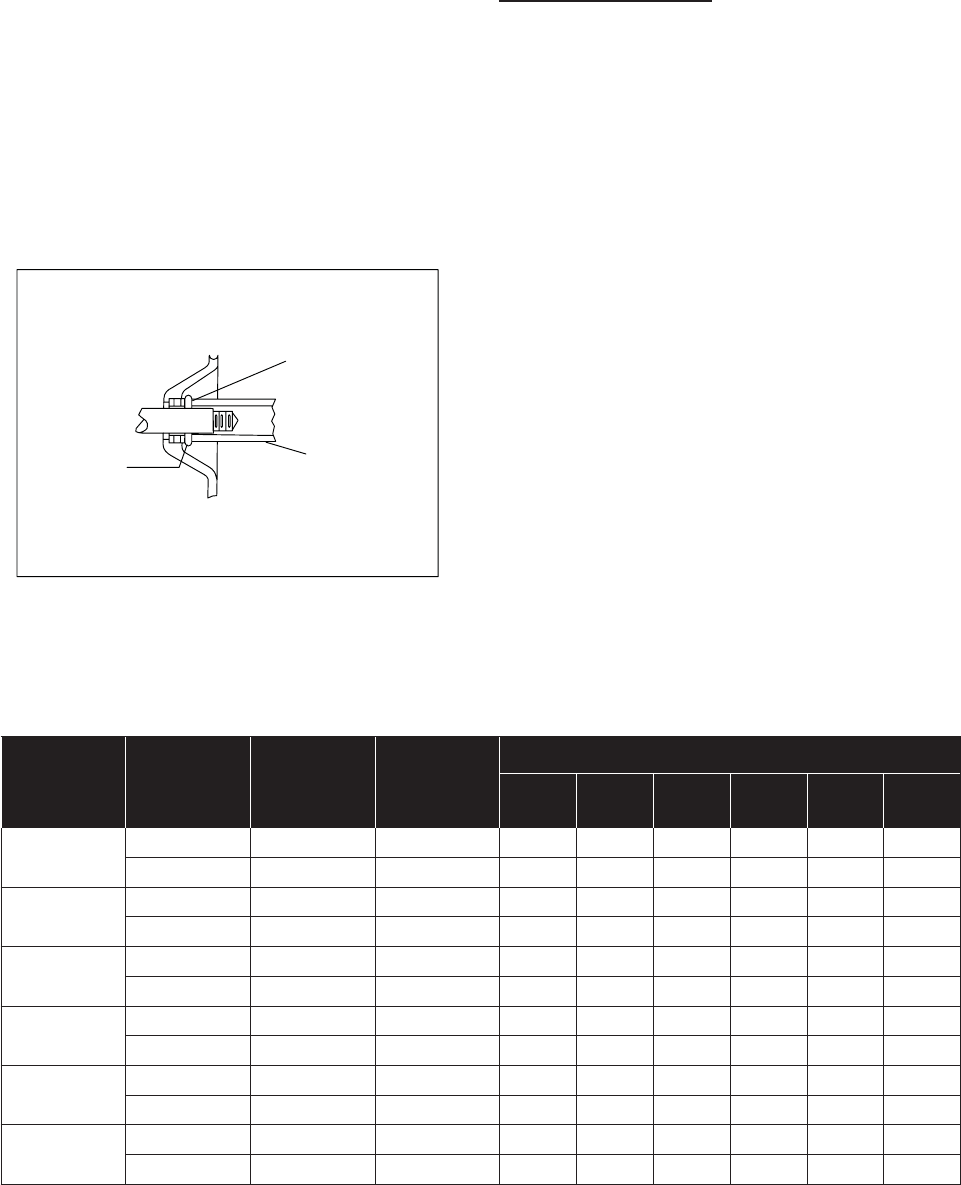

Figure 3

Cardboard

Washer

Polished surface

or seat

Pipe or Tool

HP Voltage

Branch

Max. Loads

Amperes

Fuse

Rating

Amperes

Maximum Length of Cable Size Shown

50’ 100’ 200’ 300’ 400’ 500’

1/2

115 8.6 15 14 14 10 8 8 8

230 4.3 15 14 14 14 14 14 12

3/4

115 13.2 20 12 12 8 6 6 4

230 6.6 15 14 14 14 12 12 10

1

115 16.2 25 12 10 8 6 4 2

230 8.1 15 14 14 14 12 10 10

1-1/2

115 20.8 30 10 10 8 6 4 2

230 10.4 15 14 14 12 12 10 8

2

115 21 30 10 10 6 6 4 2

230 10.5 15 14 14 12 12 10 8

2-1/2

115 23 35 1086422

230 11.2 15 14 14 12 12 10 8

Table 2 - Electrical Information