www.fmiproducts.com

55175G10

To install:

1. Remove gas line cover plate from appliance’s

outer surround at the location to be used.

2. Remove insulation from inside the gas line

conduit sleeve.

3. Run gas line through sleeve.

4. Prepare incoming black iron gas line with

Teon tape or pipe joint compound. (Check

local codes as to the use of Teon tape.)

CAUTION:Compoundsused

onthreadedjointsofgaspiping

shallberesistanttotheaction

of LiqueedPetroleum (LP or

propane)andshouldbeapplied

lightlytoensureexcesssealant

does not enter the gas line.

5. Connect incoming gas line to regulator. Secure

all joints tightly with wrench, but do not over

tighten. If a exible gas line is used, take care

not to kink the connector.

6. Re-pack insulation in and around the conduit

sleeve and exible gas line.

WARNING: All gas piping

andconnectionsmustbetested

forleaksaftertheinstallationis

completed.

After ensuring that the gas valve

ison,applyacommercialleak

detection solution to all con-

nectionsandjoints.Ifbubbles

appear,leaks canbedetected

and corrected.

Donotuseanopenameforleak

testing and do not operate any

applianceifaleakisdetected.

Typical Exterior Wall Gas

Shutoff Installation

Key

Extension

Shutoff

Valve

FIREPLACE

INSTALLATION

Continued

Figure 15 - Typical Exterior Wall Gas

Shut-Off Installation

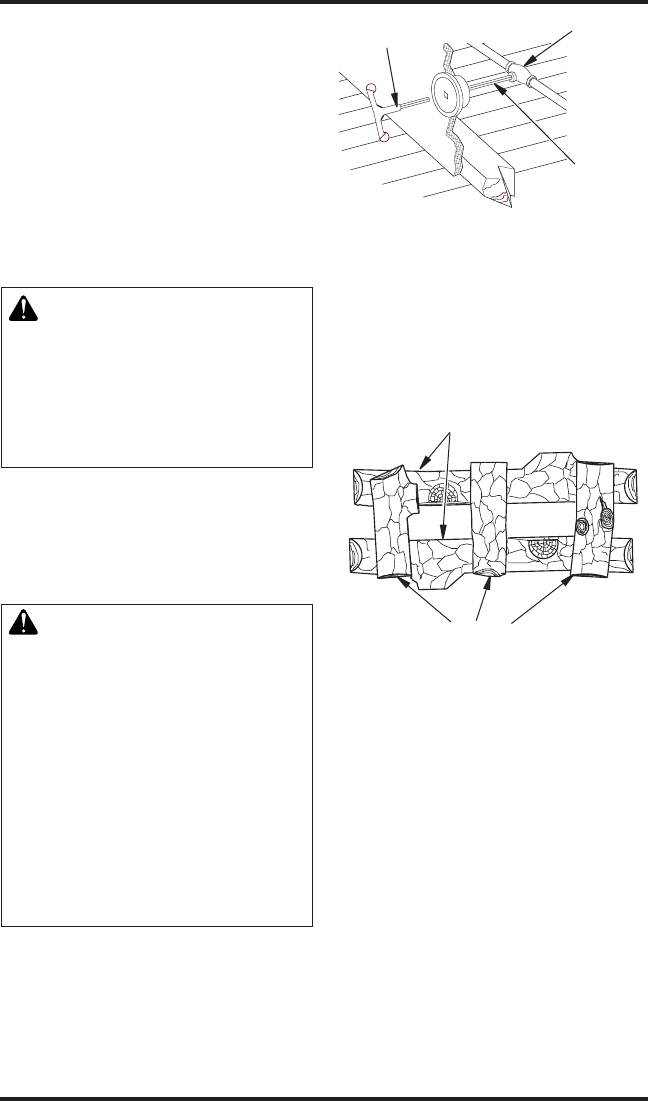

LOG SET PLACEMENT

Carefully remove log set from packaging. Place

the two bottom logs over grate and align with pins.

Place three loose logs, or twigs, onto alignment

pins on two bottom logs (see Figure 16).

Figure 16 - Log Placement

FIREPLACE FACING

Any non-combustible material may be used for

facing (glass, tile, brick, etc.) as long as the proper

clearances are adhered to and the replace open-

ings are not blocked or obstructed in any way. See

Clearances, page 6, and Figure 17 on page 11.

Use only heat-resistant, noncombustible mortar

or adhesive when securing facing material to the

front of the replace.

Bottom Logs

Top Logs (Twigs)