Type N201

2

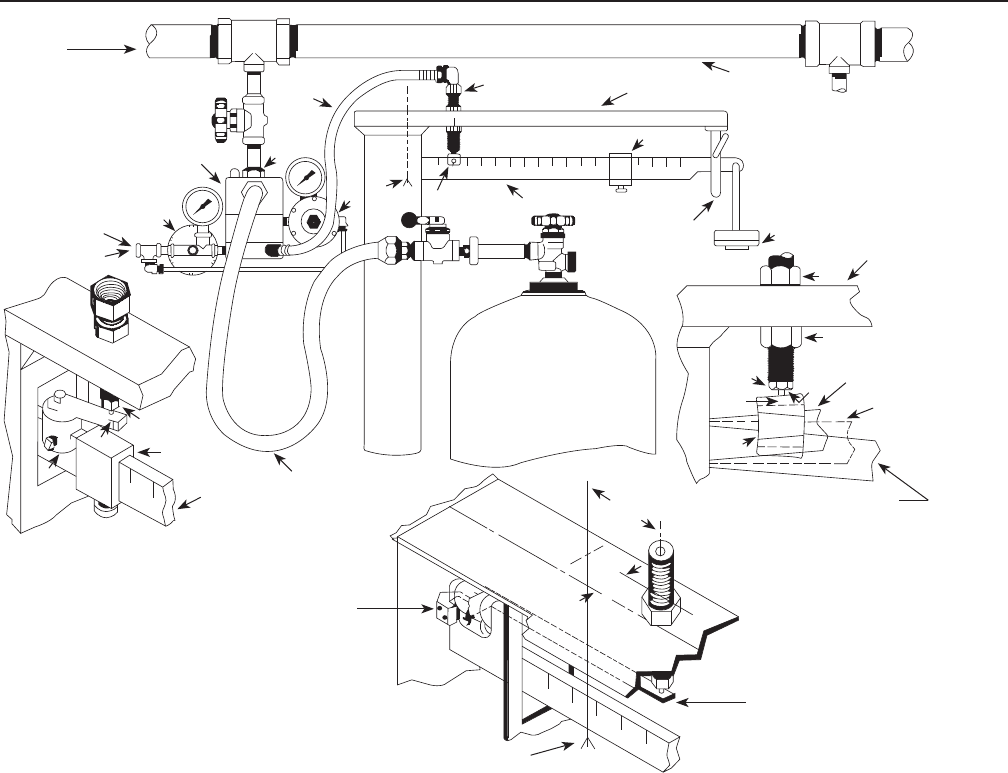

position (full cylinder). To correct this, try

raising the trip valve slightly and retighten

locknuts “D” and “E”. If raising the trip valve

does not correct the situation the 5/8-inch

(16 mm) hole on the scale frame will have to

be drilled closer to the pivot point.

3.A On installations where the slide weight “H” must be

moved to zero, alternate trip valve installation no. 1 can be

made. (This is usually necessary when both 20 pounds

(9 kg) and 100 pounds (45,4 kg) cylinders are to be filled.)

Follow steps 3 (a), (b), (c) and:

d. Place the beam button “J” on the scale beam close

enough to the pivot point to allow the slide weight to move to

zero, see drawing. If there is not enough room to permit this,

either the beam button must be ground down or the user

must make a special beam button.

e. Mount beam bar “K” on the beam button so that it extends

directly under the trip valve. The beam bar can be bent if

necessary and extra length can be cut off.

f. Make certain the beam barely contacts the trip valve

stem when the scale beam is in a level position.

3.B For Fairbanks Morse Type 1124A and 1280A scales,

alternate trip valve installation no. 2 must be made, see drawing.

a. Measure 3-inch (76,2 mm) from the pivot point as shown.

b. Measure 1 1/4-inch (31,75mm) from the scale frame

center line toward the back of the scale.

c. Drill a 5/8-inch (16 mm) hole through the scale frame

at this point.

d. Attach the beam bar “L” to the clamp “M” with two

screws, and attach the clamp to the rear of the scale beam

with two screws.

e. Remove locknut “D” and insert the trip valve through the

5/8-inch (16 mm) hole. Replace locknut.

f. Using locknut “D” and “E”, position trip valve so that

it barely contacts the beam bar ”L” with the scale in a

level position.

4. Connect supply pressure (air or gas) at point “P”.

Recommended supply pressure is at least 30 psig (2,1 bar),

since regulator 2 is set at 30 psig (2,1 bar) outlet pressure.

A 30 psig (2,1 bar) supply is sufficient for pump discharge

pressures up to 350 psig (24,1 bar). Regulator 1 is set at

3 psig (0,21 bar).

Figure 2. N201 Installation

L

PIVOT

POINT

M

F

BEAM

HORIZONTAL

(LEVEL)

BEAM IN RAISED

POSITION

D

E

STANDARD TRIP VALVE

INSTALLATION

MANIFOLD

SCALE FRAME

H

TRIP VALVE

2

PIVOT

POINT

C

I

P

H

K

J

TRIP VALVE

3

(76,2)

1 1/4

(31,8)

INCH

(mm)

TRIP

VALVE

J

J

BEAM WHEN CYLINDER

IS NOT FILLED

SCALE

FRAME

BEAM STOP

SCALE BEAM

FROM CHARGING PUMP

TRIP VALVE

HOSE

TYPE 201

FILLER VALVE

PILOT VAPOR

PRESSURE FROM

AIR COMPRESSOR

STORAGE TANK,

OR AUXILIARY

PROPANE CYLINDER

SCALE BEAM

FILLING HOSE

APPROX. 1/5

LENGTH OF

SCALE BEAM

ALTERNATE TRIP VALVE INSTALLATION # 2

(FOR TYPE 1124A AND 1280A FAIRBANKS MORSE SCALE)

ALTERNATIVE TRIP VALVE

INSTALLATION #1

A

B