Page | 11

FREESTANDING INSTALLATION

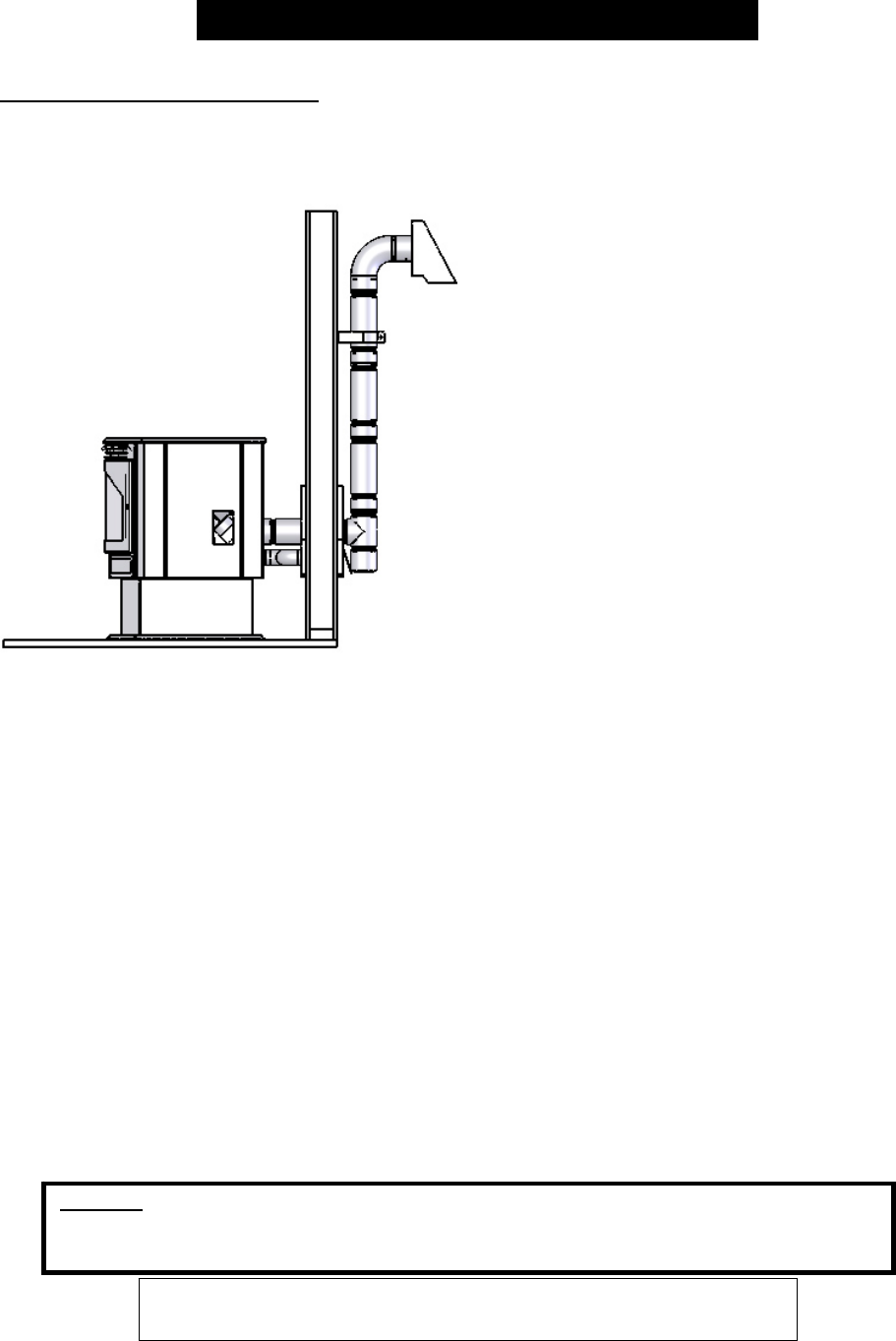

Approved Venting Method 1

: Through the Wall

Generally the simplest installation

method, venting through the wall using

our AC-3000 kit (or similar venting

system) is also the preferred venting

method. It minimizes horizontal pipe,

allows the stove to be installed close to the

wall and keeps the clean-out tee on the

outside of the house, for ease of cleaning.

When installing any venting system, Type

L or Type PL pipe must be used and all

clearances to combustibles (listed by the

pipe manufacturer) must be strictly

adhered to.

Use the pipe manufacturer’s approved

thimble for passing through a combustible

wall, and maintain at least the minimum

clearances to combustibles.

Use an appliance collar where the pellet

vent connects to the exhaust output of the

pellet stove and attach the appliance collar to the exhaust blower output using three sheet

metal screws.

Secure the pellet vent to the outside of the house using a wall strap just below the 90 degree

elbow.

Seal each pipe connection joint with high temperature RTV Silicone, to ensure the system is

leak free (Check with the specific venting system manufacturer’s instructions before doing

so).

If the pellet vent pipe being used is not a “Twist Lock” system, three (3) sheet metal screws

are required at each pipe joint.

Connect the pellet stove to outside combustion air using the kit included with your stove or

using an alternative method, as described in the “Outside Air” section, on page 15.

This installation type can be modified for basement (Basement installations should always

be performed by a professional installer) or other installations wherein the tee and vertical

section of the pipe would be inside the home and the venting system would simply pass

horizontally through the thimble and then terminate.

Please Note:

Installation diagrams are for reference purposes only and are not drawn to scale, nor meant to be used as plans for each individual

installation. Please follow all venting system requirements, maintain the required clearances to combustibles, and follow all local

codes.

For high altitude installations (above 4,000 ft.), the vent pipe should be

increased from 3-inch (3”) to four-inch (4”).