8

8”

Pre-Manufactured Flue System: In the past few years pre-manufactured flue systems have

become very popular, because this type system is easily installed and, when done correctly, is very

safe. There are many pre-manufactured flue systems on the market, and when making your choice it

should be U.L., B.O.C.A. or I.C.B.O. approved. Any of these systems are constructed of the proper

materials and meet the proper safety standards. Your local dealer normally handles an approved

brand of flue pipe. There are two very popular methods for installation of this type system.

The first, most popular and least expensive is through the ceiling and out the roof. This is the

most direct route and creates a good draw because it requires less pipe. It is less expensive because

insulated pipe is needed only from the ceiling to the roof and above -- single wall chimney connect, 24

gauge or thicker is used from the unit to the ceiling; maintain 10.5” clearance between single wall

chimney connector and any combustibles.

The second method for installing a pre-manufactured system is to exit through the wall and run the

system vertically up the outside of the structure. This method is more expensive because more

insulated pipe is required -- you must use insulated pipe through the wall and up the outside of the

structure. In either installation, proper clearances to combustibles should be maintained. Your flue

pipe manufacturer furnishes a wall thimble or ceiling support box and, when installed properly, the

correct clearances are achieved. If you are unable to install this type system your local dealer may be

able to recommend a qualified contractor for this installation. It is the customer’s responsibility to

ensure that his system is installed properly and is in good operating condition.

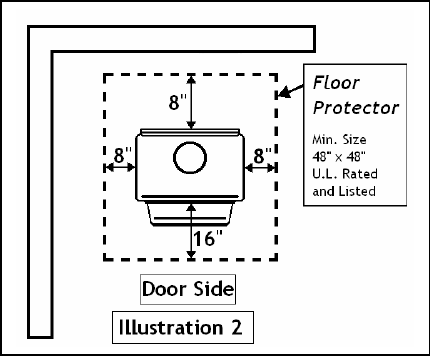

FLOOR AND WALL PROTECTION

1. Floor Protection

You will not need any floor protection if your

floor is constructed of a non-combustible material

such as brick or concrete. If your floor is

constructed with a combustible material such as

hardwood, carpet or linoleum, you must place

protection between the stove and the combustible

material.

There are many floor and wall board

manufacturers, and you should be very cautious in

choosing the proper protection. The type board you

choose should be U.L. rated and listed. After

examining the area you plan to place your stove and determining it requires a board, the next step

is to select the proper size. The stove you choose will determine the size board that is required.

The approved protector board should be large enough to provide a minimum of eight inches (8”)

behind the unit, eight inches (8”) on either side and sixteen inches (16”) in the front where the door

is located. Floor protection should also exist under the chimney connector, and should extend two

inches (50 mm) beyond each side of the chimney connector. This stove requires a minimum

standard floor protector size of 48” x 48”.

Installation on a Concrete Floor

An appliance mounted on a concrete floor does not require floor protection.

Carpeting and any other combustible material must not cover the Floor Protector.

If a combustible surface is applied to the concrete floor, a clearance must be maintained

equivalent to the area reserved for the floor protector.