12

Enerco | Compact Unit Heater Operating Instructions and Owner’s Manual

minimum of 5.0" w.c. for natural gas or 10.4" w.c. for LP/

propane

gas should be maintained for proper unit operation.

2. After line pressure has been checked and adjusted, check

manifold

pressure. Correct manifold pressure is shown on the

unit

rating plate. See figure 10 for gas pressure adjustment

screw

location. A natural gas to LP/propane gas changeover

kit

is required to convert unit. Refer to installation instructions

provided

with changeover kit for conversion procedure.

LIMIT CONTROL

The limit control switch is factory set and not field adjustable.

LOUVER VANE ADJUSTMENTS

Rotate louver vanes to direct airflow upward, downward, straight,

or

any combination of these directions. When unit is installed in an

inverted position, louvers may be positioned in the same manner.

COMBUSTION AIR PRESSURE SWITCH

This pressure switch checks for proper combustion air blower

ope

ration before allowing an ignition trial. The switch is factory

set and no field adjustment is necessary.

FLAME ROLLOUT SWITCH

The flame rollout switch(es) are located on the burner box top,

behin

d the ignition control board. This normally closed switch

opens

on a temperature rise. Check for adequate combustion air

before

manually resetting switch.

SERVICE

CAUTION Turn off gas and electrical power to unit before

performing

any maintenance or service operations on this unit.

Remember to follow lighting instructions when putting unit back

into

operation after service or maintenance.

If

any of the original wire as supplied with the appliance must be

replaced, it must be replaced with wiring material having a

tempe

rature rating of at least 105°C.

Do

not use this appliance if any part has been under water.

Immedi

ately call a qualified service technician to inspect the

appliance

and replace any gas control which has been under

water.

BURNERS

1. Periodically examine burner flames for proper appearance

during the heating season.

2. Before each heating season examine the burners for any

deposits

or blockage that may have occurred.

3. Clean burners as follows:

• Turn off both electrical and gas supplies to unit.

• Disconnect gas supply piping, high tension and sensor

leads.

Remove gas manifold. Remove burner tray.

• Clean burners as necessary. Make sure that burner

heads

line up properly to ensure flame crossover.

Che

ck spark gap on electrode and adjust if required. The

gap

should be between 0.110 inch and 0.140 inch

(2.

79mm to 3.56mm). The gap may be checked with

app

ropriately sized twist drills or feeler gauges.

• Reinstall burner tray, gas manifold, high tension and

sensor

leads. Reconnect gas supply piping.

• Restore electrical power and gas supply. Follow lighting

instructions

to light unit. Check burner flame.

FLUE PASSAGEWAY AND FLUE BOX

The flue passages and flue box should be inspected and cleaned

prior

to each heating season. The sequence of operation should be

as

follows:

1. Turn off both electrical and gas supply to unit.

2. Disconnect combustion air blower wiring.

3. Remove screws securing flue box to unit. Remove flue box. If

necessa

ry, remove blower assembly from flue box. Clean

fl

ue box with wire brush.

4. Remove turbulator retention bracket and turbulators. Clean

turbul

ators with wire brush.

5. Remove burners as described in section “BURNERS” section.

6. Clean tubes with a wire brush.

7. Reassemble unit. The combustion air and flue box gaskets

shoul

d also be replaced during reassembly.

8. Restore electrical power and gas supply. Follow lighting

instructions

to light unit. Check operation of unit.

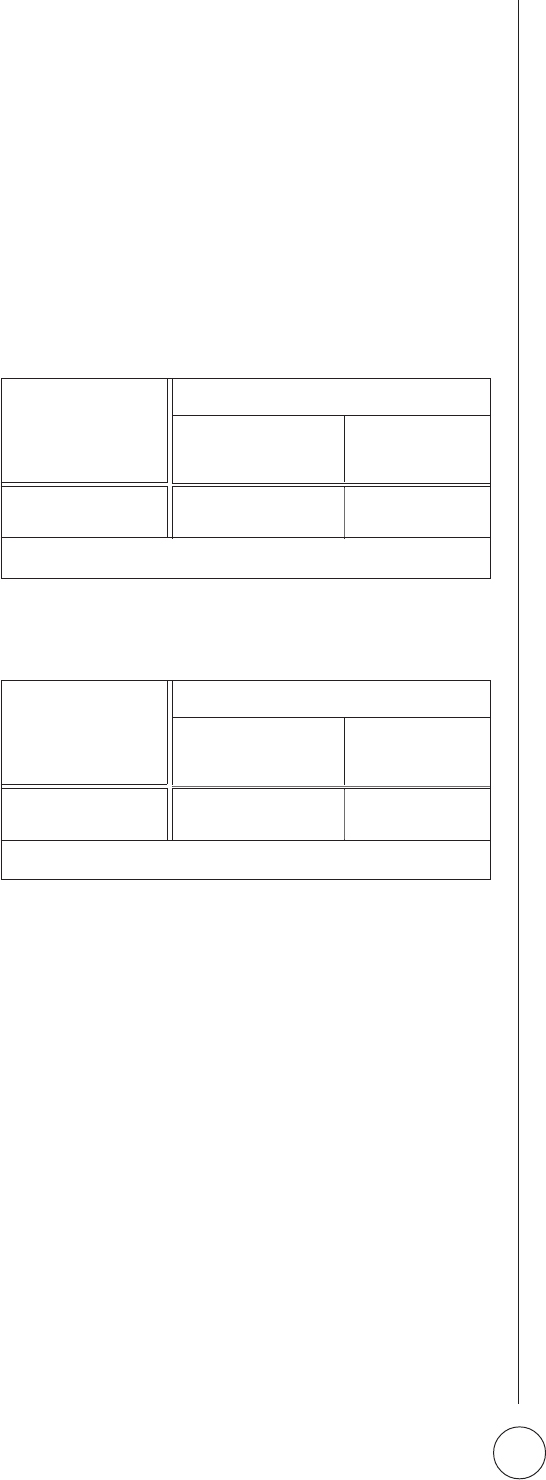

TABLE 4

NATURAL GAS MANIFOLD PRESSURES - IN.WC. (KPA)

TABLE 5

LP/P

ROPANE GAS MANIFOLD PRESSURES - IN.WC. (KPA)

ALTITUDE FT. (M)

45/75 10 (2.49)* 8.0 (1.99)

MHU

45/75 HSU45/75 0-2000 2 000-4500

(0-

610) (610-1370)

ALTITUDE FT. (M)

45/75 4.0 (0.99)* 3.6 (0.89)

MHU

45/75 HSU45/75 0-2000 2 000-4500

(0-

610) (610-1370)

*No adjustment required.

*No adjustment required.