11

Operating Instructions and Owner’s ManualEnerco | Compact Unit Heater

13. If appliance still will not operate, follow the instructions “TO

TURN

OFF GAS TO UNIT” and call your service technician or

gas

supplier.

TO TURN OFF GAS TO UNIT

1. Set thermostat to lowest level.

2. Turn off all electrical power to unit if service is to be

performed

.

3. Depress knob on gas valve; knob will snap to OFF.

HEATING SEQUENCE OF OPERATION

1. When the thermostat calls for heat, the combustion air

bl

ower starts immediately.

2. Combustion air pressure switch proves blower operation

be

fore allowing power to the ignition controller. This switch is

factory set and no adjustment is necessary.

3. After prepurge of approximately 30 seconds, the spark

ignition

is energized and the solenoid valves open in the gas

valve

.

4. The spark then ignites the gas, the ignition sensor proves the

flame

and the combustion process continues.

5. In the event that the flame is not detected after the first 10-

second

trial for ignition, the controller will repeat steps 3 and

4 an additional two times before locking out the gas valve.

Ignition

control will then automatically repeat steps 3, 4, and 5

after

60 minutes.

To interrupt the 60-minute lockout period, move thermostat

from “Heat” to “OFF” then back to “HEAT.” Heating

seq

uence then restarts at step 1.

6. The burners shall light without noticeable crossover delay.

There

shall be no flame lifting from the burner heads,

flashb

ack or burning within the burner. The flames shall be

predominantly

blue in color and shall be approximately

centered

in the tubes with no apparent impingement taking

place

.

7. The ignition control will energize the fan approximately 45

seconds

after ignition is established.

8. After the thermostat demand is satisfied the gas valve is

closed;

5 seconds after the demand is satisfied the

combustion

air blower is shut off.

9. The control center shall shut off the system fan approximately

150 seconds after the gas valve is denergized.

IGNITION CONTROL LED

The ignition control board contains a green LED which indicates the

following

:

TABLE 3

IGNITION CONTROL LED

GAS CONVERSION KIT OPTIONAL

ADJUSTMENTS

HIGH ALTITUDE

Units may be fired at full input up to 2000 ft. (610m) above sea

level. Above 2000 ft. (610m), manifold pressure must be adjusted

on

some units. Adjust pressure regulator to pressure shown in

table

4 for natural gas and table 5 for LP/propane gas.

GAS FLOW

To check for proper gas flow to the combustion chamber,

determine

the Btu input from the appliance rating plate. Divide this

input

rating by the Btu per cubic feet of available gas. Result is the

required number of cubic feet per hour. Determine the flow of gas

through

the gas meter for two minutes and multiply by 30 to get

the

hourly flow of gas.

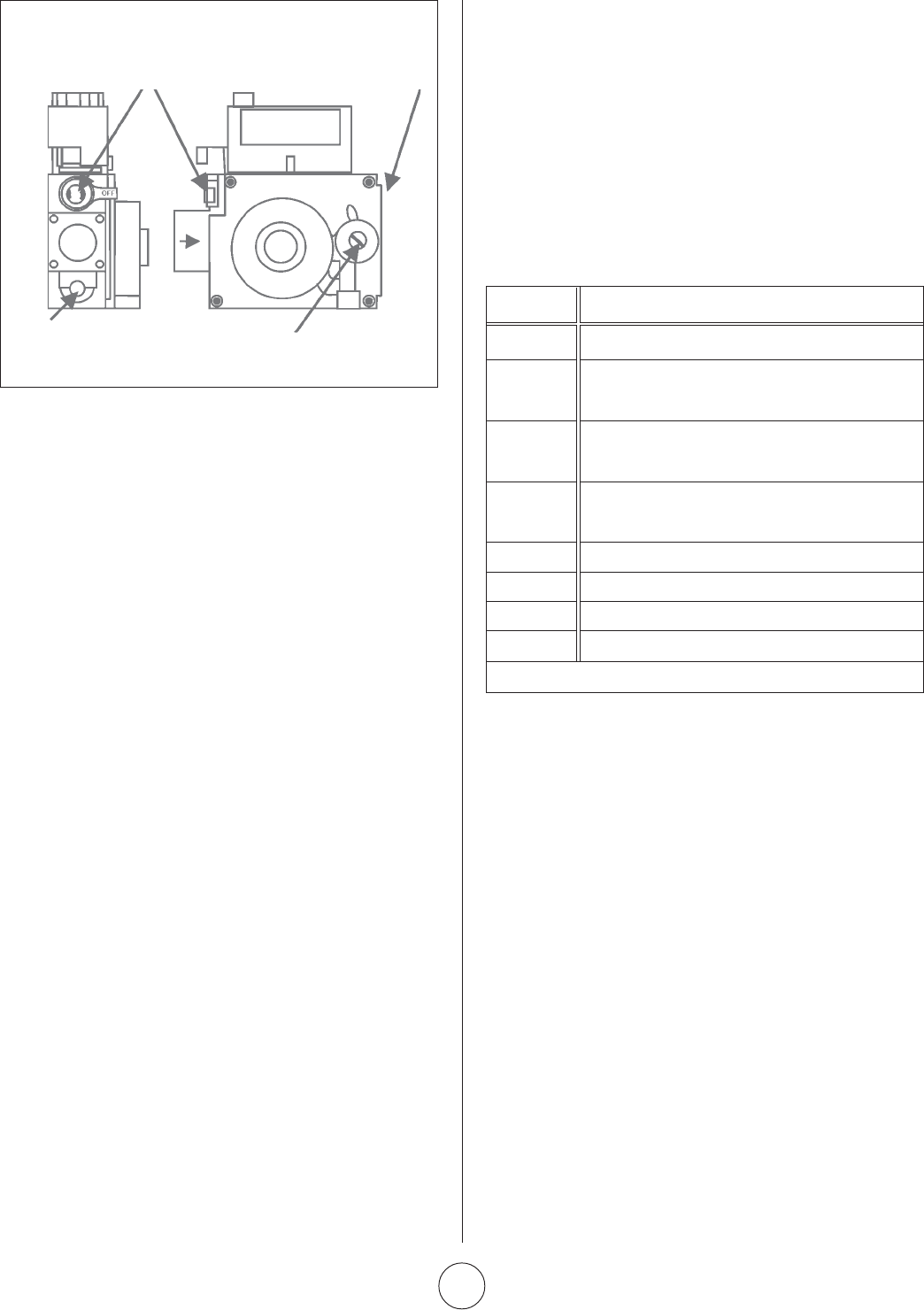

GAS PRESSURE

1. Check gas line pressure with unit firing at maximum rate. A

MANIFOLD

PRESSURE

TAP

INLET

PRESSURE TAP

ROBERTSHAW 2000DER GAS VALVE

GAS VALVE KNOB SHOWN

IN

OFF POSITION

MANIFOLD

PRESSURE ADJUSTMENT

SCREW

UNDER CAP

LED UNIT OPERATION

Slow Flash* Normal Operation - No call for heat

Fast Flash Normal Operation - Call for heat

Cur

rent signal at FLAME terminal 0.6 to 1.0 microamps

2 Flashes System lockout - failed to detect or sustain flame

Current

signal at FLAME terminal <0.6 microamps

3 Flashes Pressure switch failed closed before CAB is energized

or

failed open after CAB is energized

4 Flashes High limit or rollout switch open

5 Flashes Flame sensed and gas valve not energized

Steady

Off Loss of power

Steady On Ignition control failure

*When thermostat is placed in continuous fan mode LED will slowly flash.

FIGURE 10

Can be purchased at any Enerco / Mr. Heater dealer or direct from

the factory under the following numbers

45NG--TO-- LP-----60067 75NG--TO-- LP-----60069

45LP---TO--NG-----60066 75LP---TO--NG-----60071