21

Operating Instructions and Owner’s ManualEnerco | enerRadiant® XL Series Heater

SECTION 7

Operation & Maintenance

Sequence of Operation

1. Turn the thermostat up. When the thermostat calls for

heat, blower motor will energize.

2. When the motor approaches nominal running RPM,

the air proving switch closes and activates the ignition

module.

3. The ignition module then energizes the hot surface

igniter for a timed warm-up period (approximately 45

to 60 seconds.)

4. After the warm-up period, the gas valve is energized.

5. During the last part of the sequence, the igniter is de-

energized and is converted to a ame sensing rod.

6. If a ame is detected, the gas valve remains open.

When the call for heat is satised, and the system

control mechanism de-energizes the burner line

voltage supply, the gas valves are turned off.

7. If no ame is detected on a single-try module, the gas

valve is closed, and the module will lockout until it is

reset. Reset is accomplished by removing power from

the module for at least ve (5) seconds (thermostat

cycle required.)

8. If no ame is detected on a three-trial module, the

gas valve is closed, and a purge period begins. After

the purge, the module acts to power the igniter for a

second warm-up period, and a second trial for ignition

period. If ame is still not established, a third and

nal purge, warm-up, and trial cycle begins. After

three trials, the module will lockout until reset. Reset is

accomplished by removing power from the module for

at least ve (5) seconds (thermostat cycle required.)

9. On a three-trial module, if ame is established and

lost on the rst or second trial, the gas valve is turned

off, a purge, warm-up, and trial for ignition will occur

on a three-trial module, only three trials for ignition

are allowed per thermostat cycle.

Maintenance

For best performance, the following maintenance procedures should

be performed before each heating season:

1. Be sure gas and electrical supply to heater are off

before performing any service or maintenance.

2. Check condition of blower scroll and motor. Dirt and

dust may be blown out with compressed air, or a

vacuum cleaner may be used.

3. Check condition of burner. Carefully remove any dust

or debris from inside the burner box or burner cup.

4. Inspect the igniter. Replace igniter if there is excessive

carbon residue, erosion, breakage or other defects.

5. Check the inside of the ring tube with a ashlight. If

carbon or scale are present, scrape out the deposits

with a wire brush or rod, or metal plate attached to a

wooden pole.

6. Check to see that the burner observation window is

clean and free of cracks or holes. Clean or replace as

necessary.

7. Check the ue pipe for soot or dirt. After cleaning as

necessary, re-attach the ue pipe to the heater.

8. Outside surfaces of heater may be cleaned by wiping

with a damp cloth.

9. A qualied service agency should be contacted for

service other than routine maintenance.

10. Check vent terminal and fresh air inlet to see that they

have not been blocked during the non-heating season.

If either pipe is restricted, the air switch won’t close,

resulting in a no-heat situation.

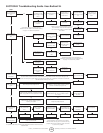

Troubleshooting

CAUTION: Before opening the Ener-Radiant XL

burner door for any type of service, be sure

the gas supply has been shut off at the heater

and the electrical cord from the burner box has

been unplugged.

Blower Motor 1. Is the thermostat calling for heat? Is there

Fails to Run: 115V at the burner receptacle?

2. Check blower side door for seal. Check door

switch. Replace if necessary/

3. Check blower for obstructions. Replace

blower if necessary.

Igniter 1. Check igniter for damage. Replace if

Does Not Glow: necessary.

2. Check voltage and resistance at igniter.

(Voltage should be 115V. Resistance should be

40-75 ohms.)

3. Check for obstructions to the air inlet and

outlet.

4. Check wiring and hose connections to the

air switch. Replace if necessary.

5. Check voltages at transformer primary and

secondary. Replace transformer or module if

necessary.

Valve Does Not Gas pressure downstream of gas control can

Come On: be measure by using a manometer and

connecting to pressure tap on control/

1. Check to see if manual valve heater is ON.

2. Check to see if manual valve knob on heater

gas control in ON.

3. Supply gas pressure can be checked at

1/8” NPT pressure tapping on heater external

manual valve.

4. Check to see if gas control is opening: no

manifold pressure indicates valve is closed.

If the valve is closed, either the gas valve or the

ignition module is faulty.

WARNING: Do not disconnect ground leads

inside heater. Do not interchange grounded

and ungrounded leads on transformer or

ignition module.

Burner Does Not 1. Check to see if gas lines were properly

Light: purged of air.

2. Check inlet and outlet gas pressure during

ignition period.

Natural inlet pressure should be 4.6”