Page 6 12425-7-0406

Note: No vent equipment supplied with furnace.

4" Oval (all parts purchase locally)

1. Type B-1 oval pipe

2. Single story type B-1 gas vents require a baseplate and one pair of

ceiling plate spacers.

3. Multi-story type B-1 gas vents require a baseplate, one pair of ceiling

plate spacers at the first floor ceiling and one pair of fire stop spacers

at each successive ceiling level.

Type B-W gas vent pipe is available for single story or

multi-story installations. Type B-W gas vent pipe is to be

used with the Listed base plate, ceiling plate spacers and fire

stop spacers.

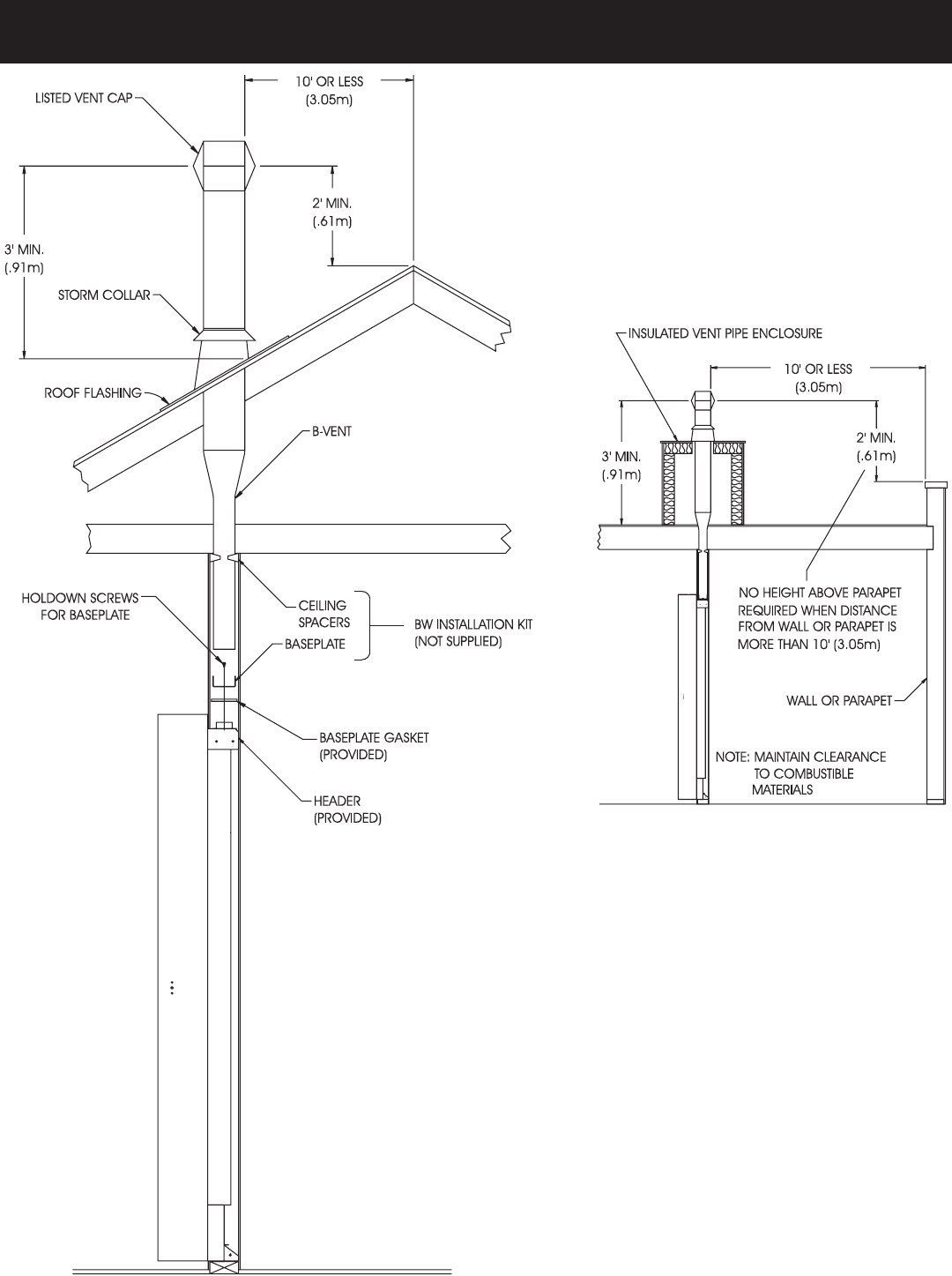

RECOMMENDED VENT CONFIGURATION

Insulated Vent Enclosure

Gravity vented wall furnaces installed in buildings with flat roofs can have

poor venting. The cold vent pipe will have a delay in proper venting and cause

the wall furnace to shut "off" by the vent safety switch. To prevent delayed

venting as well as condensation of flue products an insulated vent enclosure

is recommended.

Use Type B vent pipe and maintain at least a one inch (25mm) clearance to

combustibles.

Use metal thimble to protect vent pipe as it passes through combustibles.

Baseplate Gasket is factory installed on header. Baseplate attaches to header

with screws. B-vent snaps into and is attached to baseplate. Minimum height

of vent pipe must be six feet (1.8m) above header.

Stud space around gas vents must be free of obstructions and building paper.

Uninsulated Single-Wall Metal Pipe shall not be used outdoors in cold climates

for venting gas utilization equipment.

Attention: The main burner uses room air for combustion. As the gas/air

mixture is injected into the main burner, there is also the flow of dust and lint

particles into the main burner.

Dust and lint accumulation inside the main burner will result in a yellow main

burner flame and possible sooting inside the combustion chamber and vent pipe.

To clean main burner refer to Page 13, "Proper Main Burner Flame."