MOUNTING AND WIRINGMOUNTING AND WIRING

MOUNTING AND WIRINGMOUNTING AND WIRING

MOUNTING AND WIRING

This thermostat is configured from the factory to operate a heat/

cool, fossil fuel (gas, oil, etc.), forced air system. It is configured

correctly for any system that DOES NOT require the thermostat

to energize the fan on a call for heat. If you system is an electric

heat or heat-pump system that REQUIRES the thermostat to

turn on the fan on a call for heat, locate the ELEC/GAS switch

on the back of the thermostat (see fig. 1) and switch it to the

ELEC position. This will allow the thermostat to energize the fan

immediately on a call for heat. If you are unsure if the heating/

cooling system requires the thermostat to control the fan,

contact a qualified heating and air conditioning service person.

When the thermostat is configured for Heat Pump, the thermo-

stat will always power the circulator fan on a call for heat in the

HEAT mode. The ELEC/GAS switch must be set to match the

type of Auxiliary heat your system uses for proper operation in

the EMERgency mode.

All wiring diagrams are for typical systems only. Refer to

equipment manufacturers’ instructions for specific system wir-

ing information.

Electric/Gas Switch (Fan Option)Electric/Gas Switch (Fan Option)

Electric/Gas Switch (Fan Option)Electric/Gas Switch (Fan Option)

Electric/Gas Switch (Fan Option)

WARNING

!

Do not use on circuits exceeding specified voltage.Do not use on circuits exceeding specified voltage.

Do not use on circuits exceeding specified voltage.Do not use on circuits exceeding specified voltage.

Do not use on circuits exceeding specified voltage.

Higher voltage will damage control and could causeHigher voltage will damage control and could cause

Higher voltage will damage control and could causeHigher voltage will damage control and could cause

Higher voltage will damage control and could cause

shock or fire hazard.shock or fire hazard.

shock or fire hazard.shock or fire hazard.

shock or fire hazard.

Do not short out terminals on gas valve or primaryDo not short out terminals on gas valve or primary

Do not short out terminals on gas valve or primaryDo not short out terminals on gas valve or primary

Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring will damagecontrol to test. Short or incorrect wiring will damage

control to test. Short or incorrect wiring will damagecontrol to test. Short or incorrect wiring will damage

control to test. Short or incorrect wiring will damage

thermostat and could cause personal injury and/orthermostat and could cause personal injury and/or

thermostat and could cause personal injury and/orthermostat and could cause personal injury and/or

thermostat and could cause personal injury and/or

property damage.property damage.

property damage.property damage.

property damage.

Thermostat installation and all components of the

system shall conform to Class II circuits per the NEC

code.

Take care when securing and routing wires so they doTake care when securing and routing wires so they do

Take care when securing and routing wires so they doTake care when securing and routing wires so they do

Take care when securing and routing wires so they do

not short to adjacent terminals or rear of thermostat.not short to adjacent terminals or rear of thermostat.

not short to adjacent terminals or rear of thermostat.not short to adjacent terminals or rear of thermostat.

not short to adjacent terminals or rear of thermostat.

Personal injury and/or property damage may occur.Personal injury and/or property damage may occur.

Personal injury and/or property damage may occur.Personal injury and/or property damage may occur.

Personal injury and/or property damage may occur.

CAUTION

!

1. Remove the packing material from the thermostat. Gently

pull the cover straight off the base. Forcing or prying on

the thermostat will cause damage to the unit.

2. Connect wires beneath terminal screws on base using

appropriate wiring schematic (see figs. 2 through 4).

3. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

4. Move base out of the way. Drill mounting holes.

5. Fasten base loosely to wall, as shown in fig. 1, using two

mounting screws. Place a level against bottom of base,

adjust until level, and then tighten screws. (Leveling is for

appearance only and will not affect thermostat operation.)

If you are using existing mounting holes, or if holes drilled

are too large and do not allow you to tighten base snugly,

use plastic screw anchors to secure subbase.

6. Push excess wire into wall and plug hole with a fire-

resistant material (such as fiberglass insulation) to

prevent drafts from affecting thermostat operation.

Attach Thermostat Base to Wall

2 “AA” alkaline batteries are included in the thermostat at the

factory with a battery tag to prevent power drainage. You

must remove the battery tag to engage the batteries.

If “BATT” is displayed, the batteries are low and should be

replaced. For best results, replace all batteries with new

premium brand alkaline batteries such as Duracell

®

or

Energizer

®

. To replace batteries, press system button to

OFF, install the batteries along the top of the base (see Fig.

1). The batteries must be installed with the positive (+) end to

the left.

Battery Location

*The 24 volt neutral connection to terminal C on the thermostat is not required if you replace the batteries once a year with fresh “AA” alkaline batteries.

*The 24 volt neutral connection to terminal C on the thermostat is not required if you replace the batteries once a year with fresh “AA” alkaline batteries.

L

R

E/W1

24 VAC

120 VAC

Hot

SYSTEM

MONITOR

SWITCH

Neutral

THERMOSTAT

SYSTEM

G W2

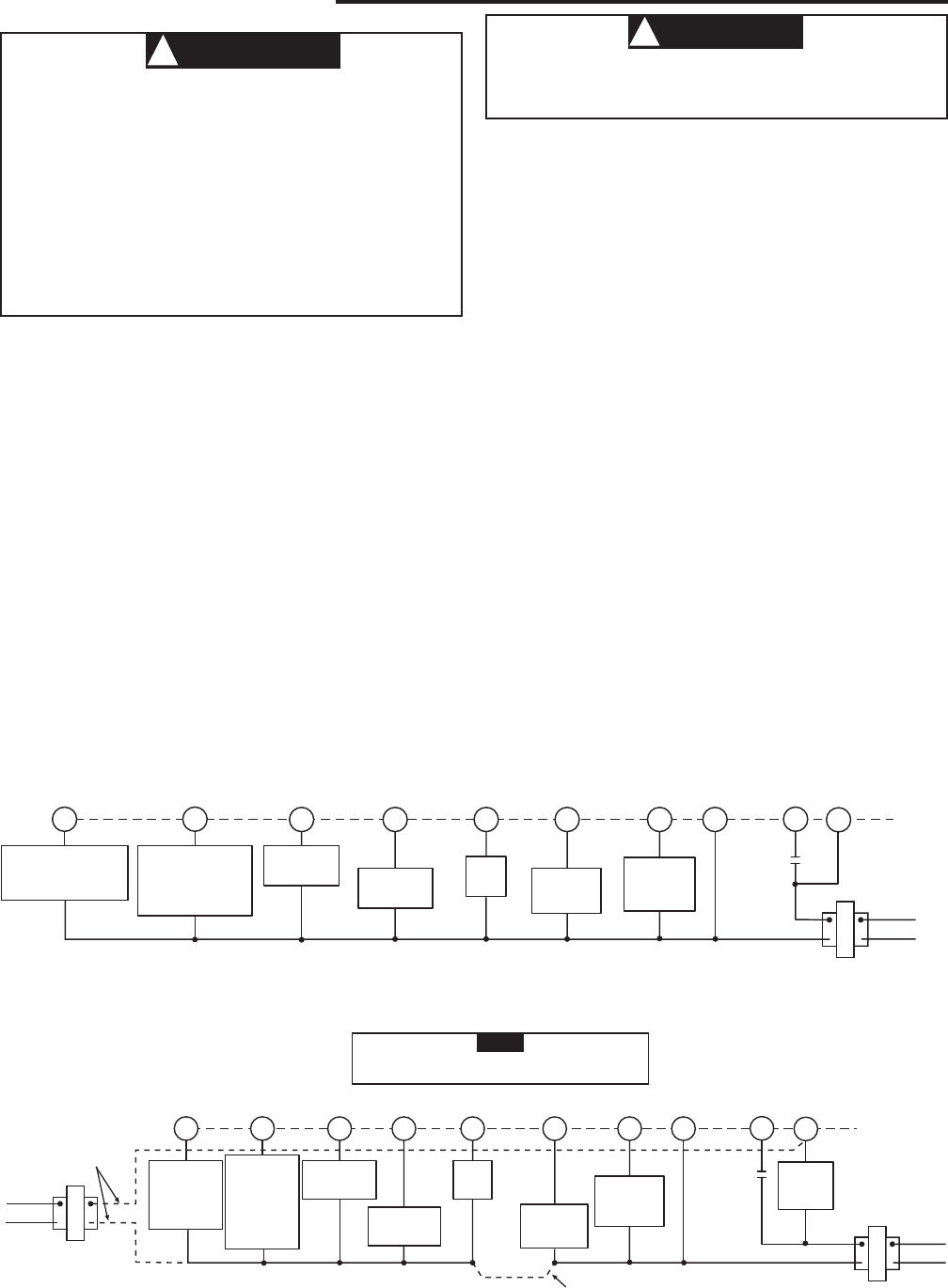

Figure 3. Typical wiring diagram for two transformer heat pump systems with NO safety circuits

TRANSFORMER

(Class II Current Limited)

2nd Stage

Compressor

CY1

Y2

Compressor

Contactor

Aux

Heat

Relay

Fan

Relay

Emergency

Heat

Relay

Limit or

Safety

Switches

TWO COMMONS MUST

BE JUMPERED TOGETHER!

HOT

NEUTRAL

120 VAC

24 VAC

CUT AND

TAPE OFF!

If safety circuits are in only one of the systems, remove

the transformer of the system with NO safety circuits.

NOTE

Reversing

Valve

Energized in

Heat, Off,

Emergency

Mode

B

Reversing

Valve

Energized in

Cool Mode

O

*

L

R

E/W1

24 VAC

120 VAC

Hot

SYSTEM

MONITOR

SWITCH

Neutral

THERMOSTAT

SYSTEM

G W2

Figure 2. Typical wiring diagram for single transformer heat pump systems

TRANSFORMER

(Class II Current Limited)

2nd Stage

Compressor

CY1

Y2

Compressor

Contactor

Aux

Heat

Relay

Fan

Relay

Emergency

Heat

Relay

Reversing Valve

Energized in Heat,

Off, Emergency

Mode

B

Reversing Valve

Energized in Cool

Mode

O

*