4. FAN SPEED SELECTION - At this point

the installer must choose between Normal/

High Fan or permanent High Fan option.

Option 1 - The heater is factory set at Normal

Fan. The fan will therefore:-

(a) Run at NORMAL when the boost option

is not selected.

(b) Run at NORMAL when the boost is

selected and the core is partially

depleted.

(c) Automatically switch to HIGH when the

boost is selected and the core is almost

fully depleted.

Option 2 - If a High Fan is permanently

required the installer must make the

following adjustment.

(a) Loosen the two screws securing the

wires to the resistor block.

(b) Move the right wire to the left of the block

and tighten both wires in the left

connection point of the resistor block

effectively taking the resistor out of

circuit.

See Fan/Boost Circuit Diagram

5. Ensure that any slack is pulled back

through each clamp and tighten the

clamping screws. Secure cables to base of

heater using ties provided in fixing kit.

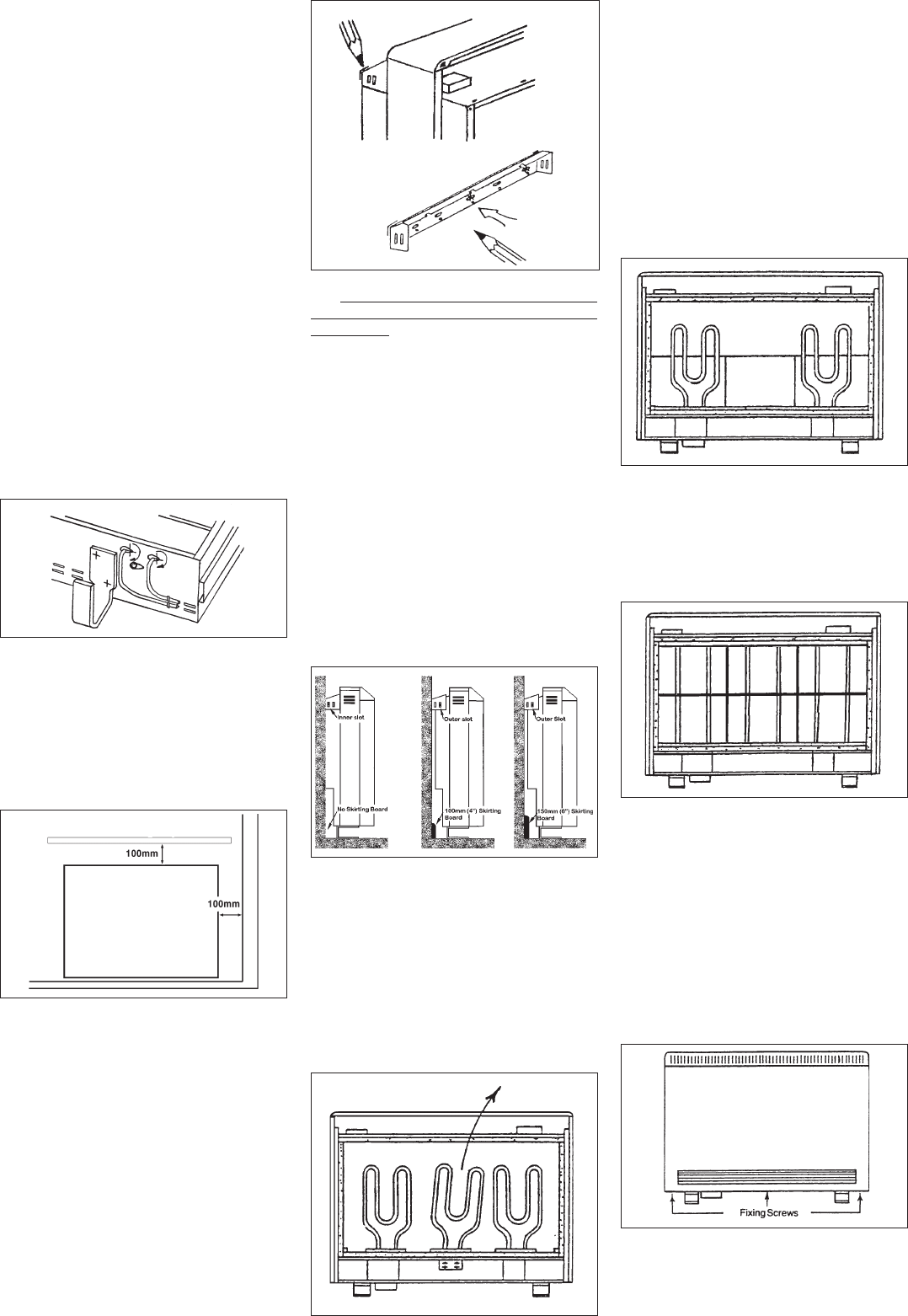

6. Place the heater on its feet, and in the

desired position against the wall - DO NOT

LIFT THE HEATER BY ITS TOP PANEL!

Ensure that the heater is based on a firm

level surface, at least 100mm from any end

wall, and at least 100mm below any shelf

or similar projection. Cut away the gripper

rod or carpet which would prevent the

heater sitting firmly on the floor.

7. Mark the position of the two outside

corners of the wall bracket with the heater

pushed tight against the wall. Remove the

wall bracket from the heater by removing

the screw at each end. Place the heater to

one side and reposition the bracket against

the wall using the corner marks for

alignment.

Four fixing positions must be chosen for

the FXL24N and three for the FXL18N. Mark

the positions for the fixing holes - two at the

extreme ends and others spaced evenly

between them. Remove the bracket from

the wall, drill the holes in the positions

marked, and insert suitable fixings

previously described. Secure the wall

bracket to the wall using the correct

fasteners.

8. THE FOLLOWING MUST BE APPLIED

WHEN FIXING THE HEATER TO THE WALL

BRACKET.

i) If no skirting board is present secure

the heater through the wall bracket slots

closest to the wall.

ii) If 100mm (4 in.) skirting is present

secure the heater through the outer

slots.

iii) If skirting taller that 150mm (6in.) is

present this must be reduced to 150mm

(6 in.) over the entire width of the heater

plus 25mm (1 in.) at each end.

Do not fully tighten these screws until the

bricks are loaded into the heater as some

settling of the heater may occur.

NOTE: NEVER REMOVE THESE SCREWS

WITHOUT FIRST UNLOADING THE

HEATER.

9. Remove one element to allow access

for the back rows of bricks. On the FXL24N

remove the element to the right of centre

and on the FXL18N remove the central

element.

Loosen the two screws securing the

element tails in the ceramic connector

block, and lift the element up and out of the

heater.

10. Carefully fit the bottom row of the

back layer of bricks placing the two end

bricks into position first. Ensure that the

recess in the bricks is toward the rear of

the heater with the narrow end to the

bottom. Repeat this with the top row of

the back layer of bricks but the narrow

end of the recess must be to the top.

Refit the element which had been removed

by feeding the tails down through the hole

in the base insulation and into the connector

block. Ensure the element is fully pushed

home, then securely tighten the two screws

in the block.

11. Fit the front layer of bricks with the

recess toward the front of the heater.

The complete core will comprise:

FXL18N : 3 x 4 brick columns

FXL24N : 4 x 4 brick columns

12. Replace the inner front, complete

with insulation, by locating its bottom edge

behind the front lip of the chassis and

inserting the retaining screws along the top

and sides.

Refit the three inner guards in their

respective locations.

Replace the outer front by hooking the

upper grille into its retaining slot on the top

panel, lower into position and replace the

three self tapping screws along the bottom

edge.

13. Finally, tighten the screws at each

end of the wall bracket. Ensure that all

screws have been tightened as this is

essential to maintain earth continuity.