www.desatech.com

116240-01E 21

7. Check to make sure that the power cord is com-

pletely clear of the blower wheel and that there

are no other foreign objects in blower wheel. Also

double check all wire leads and make sure wire

routing is not pinched or in a precarious position.

Correct accordingly.

8. Turn on power to duplex outlet if previously

turned off per the warning in column 1,

page 19.

9. Plug in blower power cord to duplex outlet.

10. The blower will only run when the speed control

knob is in the ON position and the thermal switch

senses temperature after the replace begins to

heat up. The blower speed can be adjusted by

rotating the control knob. To turn off, turn knob

fully counterclockwise until it clicks off. If the

blower is ON and has been running with the

replace operating, the blower will continue to

run for a short time after the replace has been

turned off. As the thermal switch cools down, the

blower shuts down automatically.

11. Peel off the backing paper and stick the sup-

plied wiring diagram decal on the rebox bot-

tom approximately 12" in front of the blower

(see Figure 27, page 20).

-

FIREPLACE

INSTALLATION

Continued

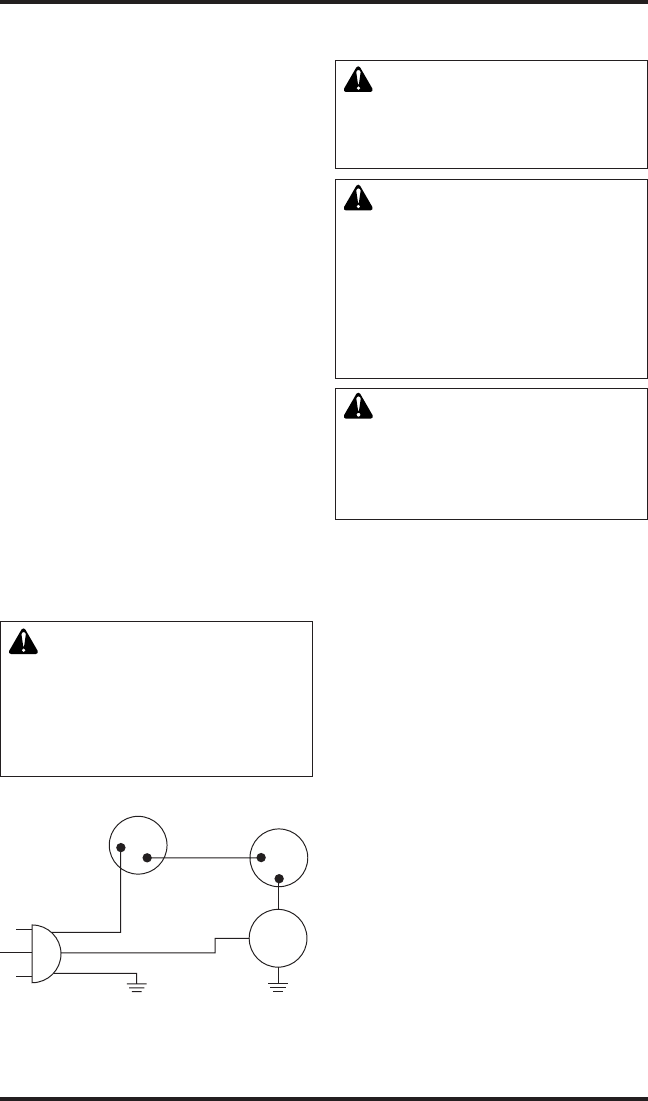

Figure 29 - Blower Wiring Diagram for

Thermostat-Controlled Models

Blue

Variable

Fan Switch

Fan Switch

(N.O.)

Green

White

On

110/115

V.A.C.

Blower

Motor

Black

Off

1

2

Black

INSTALLING GAS PIPING TO

FIREPLACE LOCATION

-

is commonly known as wellhead

Installation Items Needed

Before installing replace, make sure you have

the items listed below.

• external regulator (supplied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• test gauge connection *

• sediment trap

• tee joint

• pipe wrench

• approved exible gas line with gas connector

(if allowed by local codes)

* A CSA design-certified equipment shutoff

valve with 1/8" NPT tap is an acceptable alterna-

tive to test gauge connection. Purchase the CSA

design-certied equipment shutoff valve from

your retailer.

For propane/LP connection only, the installer must

supply an external regulator. The external regula-

tor will reduce incoming gas pressure. You must

reduce incoming gas pressure to between 11" and

14" of water. If you do not reduce incoming gas

pressure, replace regulator damage could occur.

Install external regulator with the vent pointing

down as shown in Figure 30, page 22. Pointing the

vent down protects it from freezing rain or sleet.