111826-01F

For more information, visit www.desatech.com

12

INSTALLATION

Continued

* Purchase the optional CSA design-cer ti fi ed equipment shutoff valve

from your dealer. See Accessories, page 27.

**Minimum inlet pressure for purpose of input adjustment.

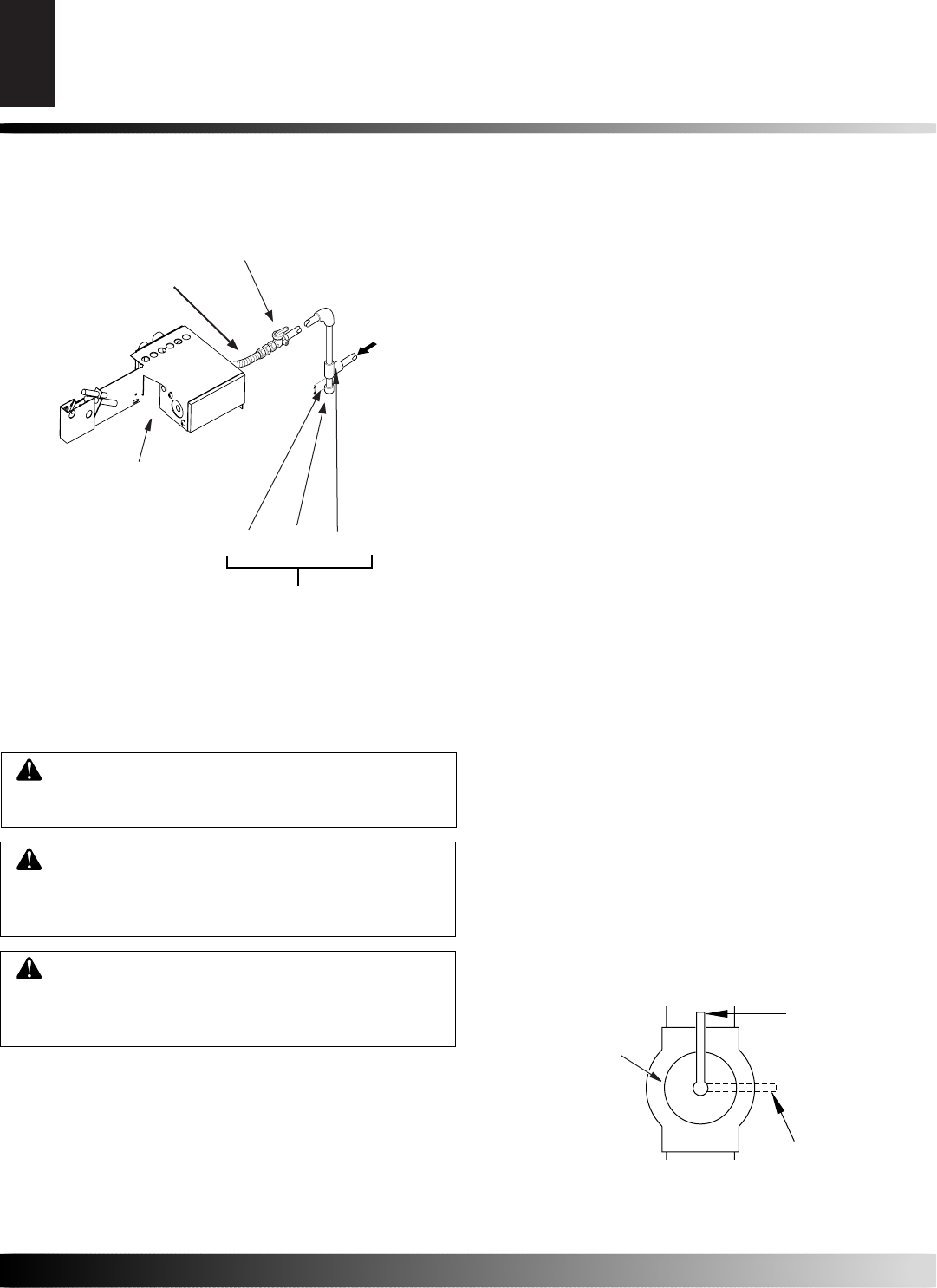

Figure 13 - Gas Connection (Remote-Ready Models Only)

Gas Control

Pipe Cap Tee

Nipple Joint

3" Minimum

Sediment Trap

PROPANE/LP

- From External

Regulator

(11" W.C.**

to 14" W.C.

Pressure)

NATURAL

- From Gas

Meter

(5" W.C.**

to 10.5" W.C.

Pressure)

CSA Design-Certifi ed Equipment

Shutoff Valve With 1/8" NPT Tap*

Approved Flexible

Gas Hose (if allowed

by local codes)

WARNING: Test all gas pip ing and connections

for leaks after in stall ing or serv ic ing. Cor rect all leaks

at once.

WARNING: Never use an open fl ame to check for

a leak. Apply a noncorrosive leak detection fl u id to

all joints. Bub bles form ing show a leak. Correct all

leaks at once.

CAUTION: Make sure ex ter nal regulator has been

installed between propane/LP supply and heat er. See

guidelines under Con nect ing to Gas Sup ply, page

11.

Pressure Testing gas Supply Piping system

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect appliance with its appliance main gas valve (control

valve) and equip ment shutoff valve from gas sup ply pip ing

sys tem. Pres sures in ex cess of 1/2 psig will dam age heat er

reg u la tor.

CHECKING GAS CONNECTIONS

INSTALLATION

Connecting To Gas Supply (Cont.)

Checking Gas Connections

Figure 14 - Equipment Shutoff Valve

ON

POSITION

OFF

POSITION

Equipment

Shutoff

Valve

2. Cap off open end of gas pipe where equip ment shutoff valve

was con nect ed.

3. Pressurize supply pip ing sys tem by ei ther opening pro pane/LP

sup ply tank valve for propane/LP gas or opening main gas valve

lo cat ed on or near gas meter for natural gas, or using com pressed

air.

4. Check all joints of gas supply pip ing system. Apply non cor ro sive

leak detection fl u id to all joints. Bubbles form ing show a leak.

5. Correct all leaks at once.

6. Reconnect heater and equipment shutoff valve to gas supply.

Check re con nect ed fi ttings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Fig ure 14).

2. Pressurize supply pip ing sys tem by ei ther opening pro pane/LP

sup ply tank valve for propane/LP gas or opening main gas valve

lo cat ed on or near gas meter for natural gas, or using com pressed

air.

3. Check all joints from gas meter to equip ment shutoff valve for

natural gas or pro pane/LP sup ply to equip ment shutoff valve for

propane/LP (see Figure 15, page 13). Ap ply non cor ro sive leak

detection fl u id to all joints. Bub bles form ing show a leak.

4. Correct all leaks at once.

Pressure Testing Heater Gas Connections

1. Open equipment shutoff valve (see Fig ure 14).

2. Open main gas valve located on or near gas meter for natural

gas or open pro pane/LP supply tank valve.

3. Make sure control knob of heater is in the OFF position.

4. Check all joints from equipment shutoff valve to gas control

(see Fig ures 15 and 16 page 13). Ap ply non cor ro sive leak

de tec tion fl u id to all joints. Bub bles form ing show a leak.

5. Correct all leaks at once.

6. Light heater (see Operating Heater, pages 14 through 16).

Check all other internal joints for leaks.

7. Turn off heater.

(OPEN)

(CLOSE)