NOTICE: A qualified heating contractor MUST inspect the heat exchanger in this

furnace at least once a year. If heavy deposits are found, immediate cleaning is

required.

All heat exchanger surfaces should be as clean as possible for the most efficient

operation of the furnace. The heat exchanger may require cleaning after every heating

season, as combustion of fuel oil tends to produce soot, particulate matter, and scale,

due to corrosion. These materials coat the inner walls of the heat exchanger. This

coating reduces the heat transfer effectiveness of the heat exchanger and can hinder

the flow of flue gases from the furnace.

NOTICE: Accumulation of heavy soot deposits over one heating season may

indicate the oil burner is out of adjustment.

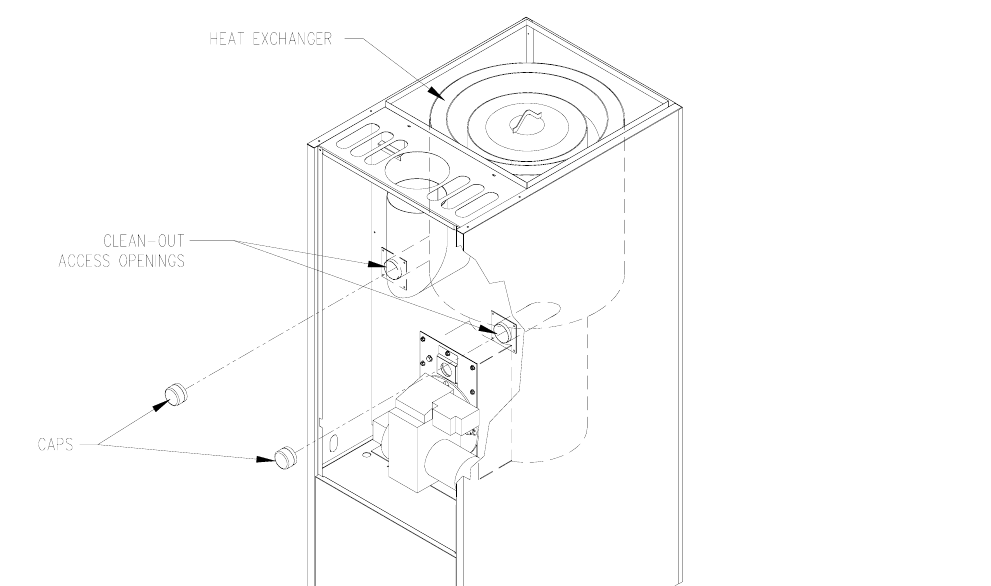

The heat exchanger may be inspected and cleaned through two (2) access, or cleanout,

ports located in the burner compartment, on highboy and lowboy models, or protruding

through the front casing panel, on the horizontal/counterflow model. Each cleanout port

consists of a 2-inch O.D. tube closed by a pressed-in cap, refer to Figure 9.

Figure 9: Location and Design of the Highboy Heat Exchanger Cleanout Ports

Using a screwdriver, or a large pair of adjustable jaw pliers, remove each cleanout port

cap. With the aid of a portable light source, peer into the heat exchanger. As much as

possible, loosen all material and deposits clinging to the heat exchanger walls using

wire brushes, or any suitable tool. Collect and remove this material by hand or with the

assistance of a vacuum cleaner and a nozzle-type attachment.

34