30

29

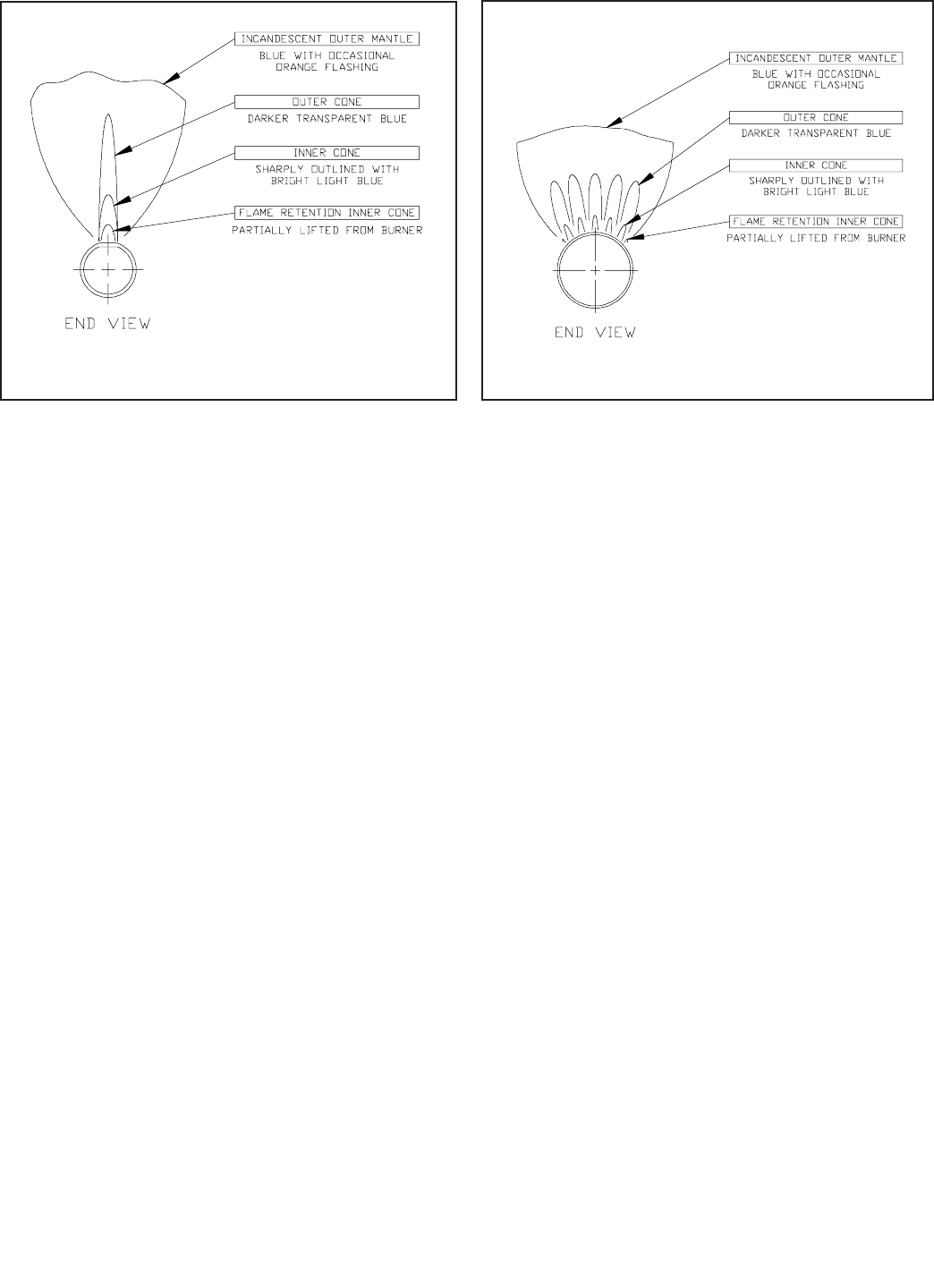

FIGURE 22a: MAIN BURNER FLAME - 1” BURNERS

FIGURE 22b: MAIN BURNER FLAME - 40mm

(“HIGH ALTITUDE”) BURNERS

17) Test thermostat operation while the boiler is running. Turn the thermostat to the lowest setting. For standing pilot boiler

models, pilot burner should remain lit but the main burners should stop firing. For intermittent ignition boiler models both pilot

burner and main burners should stop firing. Raise the thermostat back to the highest setting. The main burners (for standing

pilot boiler models) or pilot burner and main burners (for intermittent ignition boiler models) should relight.

18) Verify low water cutoff operation while the boiler is running. Slowly open drain valve and drain boiler until the water level

drops below low water cutoff line. Water still should be visible in the gauge glass when the low water cutoff shuts down the

main burners. For standing pilot boiler models, pilot burner should remain lit when the main burners stop firing. For

intermittent ignition boiler models both pilot burner and main burners should stop firing. Make sure pressure limit, thermostat

or other controls have not shut off the boiler. Upon test completion refill the boiler to the normal water level.

19) Check pressure limit control operation. When steam pressure is registered on pressure gauge, lower pressure limit setting

below gauge reading. For standing pilot boiler models, pilot burner should remain lit when the main burners stop firing. For

intermittent ignition boiler models, both pilot burner and main burners should stop firing. Raise pressure limit setting above

gauge reading. The main burners( for standing pilot boiler models) or pilot burner and main burners ( for intermittent ignition

boiler models) should relight.

20) After the boiler has operated for approximately 30 minutes, check the boiler and heating system piping for leaks. Repair any

leaks found at once.

21) Inspect the vent system for flue gas leaks. Repair any leaks found before leaving the boiler in operation.

22) Replacement of a steam boiler tends to break loose accumulated scale from the system. During the first week of operation,

blow down the #67 low water cut-off at least three times following the blow down instructions on the yellow sticker adjacent

to the low water cut-off.

23) After new boiler has been installed and put into continuous operation for several days, clean the boiler of oil, grease,

sludge, and other contaminants that may have been present in existing piping. This will prevent unsteady water line and

water carry over into supply main. The boiler boil-out should be done as follows:

a) Turn off gas supply to boiler per the appropriate Lighting and Operating instructions on page 25 - 28.

b) Drain water from boiler until about one inch of water is visible in gauge glass.

c) Run a hose or temporary piping from the boiler drain valve to a location where hot water can be safely discharged.

Drain approximately five gallons of water from the boiler and mix-in an appropriate amount of an approved boil-out

compound. Remove safety valve and refill the boiler with prepared solution through funnel inserted into elbow under

the safety valve. Run a hose or temporary piping from safety valve tapping to a location where hot water can be

safely discharged. DO NOT INSTALL ANY VALVES IN THIS LINE.

d) Light off the boiler per the appropriate instructions on page 25 - 28. Run boiler for several hours, boiling the water,

without generating steam pressure. Open the water feed valve sufficiently to allow a slight overflow of water through

the safety valve tapping drain line. Continue boiling until water coming out is clear.