17

Installation & Operation Manual

Vent, air piping and termination:

The Crest vent and air piping can be installed through the roof

or through a sidewall. Follow the procedures in this manual for

the method chosen. Refer to the information in this manual to

determine acceptable vent and air piping length.

Air contamination

Pool and laundry products and common household and hobby

products often contain fluorine or chlorine compounds. When

these chemicals pass through the boiler, they can form strong

acids. The acid can eat through the boiler wall, causing serious

damage and presenting a possible threat of flue gas spillage or

boiler water leakage into the building.

Please read the information given in Table 1A, page 9,

listing contaminants and areas likely to contain them. If

contaminating chemicals will be present near the location of the

boiler combustion air inlet, have your installer pipe the boiler

combustion air and vent to another location, per this manual.

If the boiler combustion air inlet is located

in a laundry room or pool facility, for

example, these areas will always contain

hazardous contaminants.

To prevent the potential of severe personal

injury or death, check for areas and products

listed in Table 1A, page 9 before installing

the boiler or air inlet piping.

If contaminants are found, you MUST:

• Remove products permanently.

—OR—

• Relocate air inlet and vent

terminations to other areas.

Removing from existing vent

Follow the instructions in Section 1, page 10 of this manual

when removing a boiler from an existing vent system.

Vent and air piping

Vent and air system:

Installation must comply with local

requirements and with the National Fuel

Gas Code, NFPA 54 / ANSI Z223.1 for U.S.

installations or CSA B149.1 for Canadian

installations.

You must also install air piping from outside to the boiler

air intake adapter. The resultant installation is direct vent

(sealed combustion).

You may use any of the vent/air piping methods covered in

this manual. Do not attempt to install the Crest using any

other means.

NOTICE

ƽ WARNING

ƽ WARNING

ƽ WARNING

When determining equivalent combustion air and vent

length, add 5 feet (1.5m) for each 90° elbow and 3 feet (.9 m)

for each 45° elbow.

EXAMPLE: 20 feet (6 m) of pipe + (4) 90° elbows + (3) 45°

elbows = 49 equivalent feet (15 m) of piping.

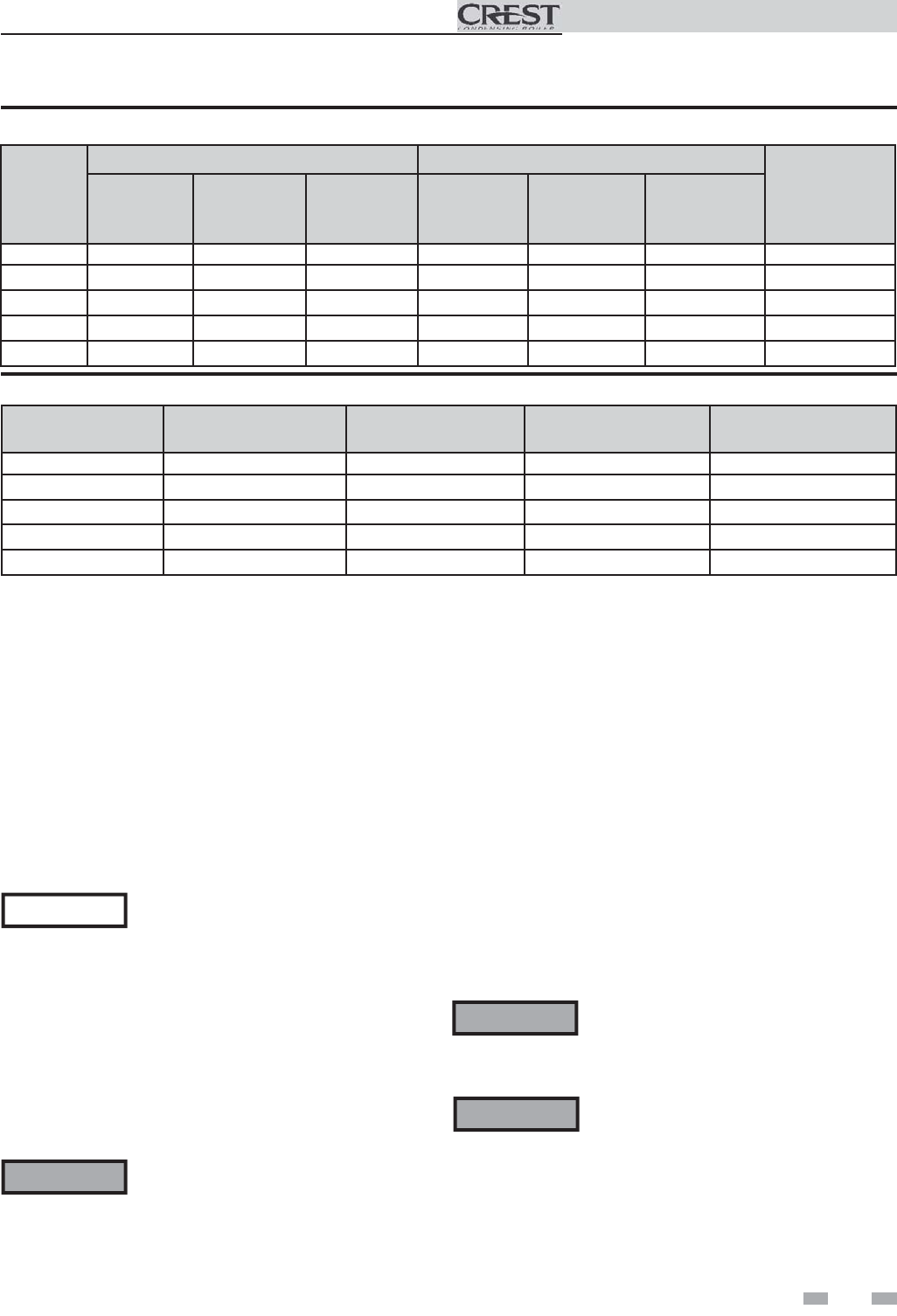

Model

AIR INLET VENT

Input

De-Rate per

25 feet of Vent

Air Intake

Diameter

Air Intake

Min. Length

Air Intake

Max. Length

Vent

Diameter

Vent

Min. Length

Vent

Max. Length

FB 1500 7" 12' 100' 7" 12' 100' 2%

FB 2000 8" 12' 100' 8" 12' 100' 2%

FB 2500 8" 12' 100' 9" 12' 100' 2%

FB 3000 10" 12' 100' 10" 12' 100' 2%

FB 3500 10" 12' 100' 10" 12' 100' 2%

Table 2B Direct Vent Minimum / Maximum Allowable Air / Vent Lengths

Model

Vent

Diameter

Vent

Min. Length

Vent

Max. Length

Input De-Rate per

25 feet of Vent

FB 1500 7" 12' 100' 1%

FB 2000 8" 12' 100' 1%

FB 2500 9" 12' 100' 1%

FB 3000 10" 12' 100' 1%

FB 3500 10" 12' 100' 1%

Table 2C Room Air Minimum / Maximum Allowable Air / Vent Lengths

2 General venting (continued)

DO NOT mix components from different

systems. The vent system could fail,

causing leakage of flue products into the

living space. Use only approved stainless

steel pipe and fittings.