SERVICE

MAINTAINING YOUR PUMP

Lubrication

It is not necessary to lubricate the pump or its motor• The motor

bearings are lubricated for life. The mechanical shaft seal in the

pump is water lubricated and selt:adjusting.

Draining for Winter

When the pump is to be disconnected from service, or is in dan-

ger of freezing, it must be drained. The pump has a draincock

which must be opened. Remove the priming plug to vent the

pump. Drain the pressure tank. Drain all piping to a point below

the freezing line.

To drain an air volume control (AVC), remove the tubing. Turn the

AVC upside down. This will permit any water to drain into tank.

Dis, assembly and Assembly of Pump

The Hydroglass* Pump is designed for ease in servicing and main-

tenance.

1. Disassemble pump as follows:

A Disconnect power.

B. Open faucet to relieve pressure.

C. Drain pump by opening draincock. Remove pressure switch

tubing from fitting on top of pump.

D. Remove clamp, Key No. lO, Page 11.

E. Remove pump base mounting bolts. Motor assembly and

back half assembly of pump can be pulled away from front

half.

F. Remove O-Rings.

2. Reassembly of pump.

A. Clean O-Rings and O_Ring grooves.

B. Lubricate O-Rings with petroleum jelly, and place in grooves•

C. Slide pump halves together.

D. Clean inside of clamp. Place clamp around pump halves.

Ahemately tighten clamp screw and tap clamp around out-

side with plastic mallet. This will insure proper seating of O-

; Ring and clamp.

E. Assemble base mounting bolts• Connect pressure switch tub

ing and close draincock.

F. prime pump and turn on power.

REMOVING MOTOR FOR SERVICE AND

REPLACING SHAFT SEAL

If it is necessary to remove motor, always replace the shaft seal. We

suggest you purchase this item, UIO9_A, and have it on hand for

future use.

NOTICE: The seal consists of two parts, a rotating member and a

ceramic seat. The surfaces of the seal are easily damaged. Read in-

structions carefully.

Remove motor as follows:

1. Disassemble pump per instructions above.

2. Remove diffuser and impeller as follows (Key Nos. 7 and 8, Page

10.

A. Remove ,_rews holding diffuser.

B. Loosen two screws and remove motor canopy.

C. If motor has capacitor, partially unscrew capacitor clamp and

move capacitor to one side•

e _

[AWARNINGJ Risk of electrical shock Do not touch ca-

pacitor terminals with body or any metal object.

D. Hold motor shaft with a 7/16" wrench on the shaft flats.

E. Turn impeller counterclockwise when facing it.

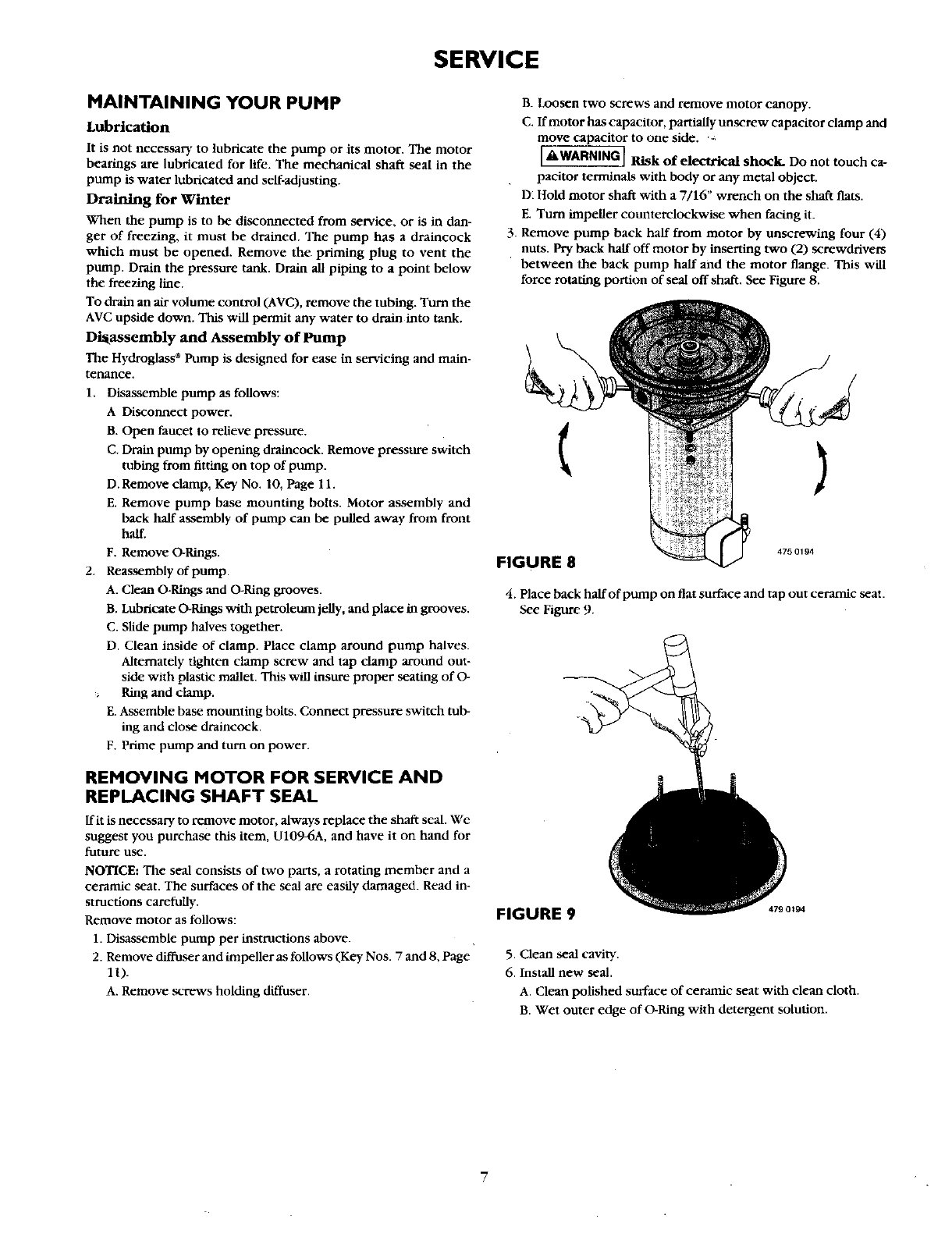

3. Remove pump back half from motor by unscrewing four (4)

nuts. Pry back half off motor by inserting two (2) screwdrivers

between the back pump half and the motor flange. This will

force rotating portion of seal off shaft. See Figure 8.

(

)

FIGURE 8

4750194

4. Place back half of pump on flat surface and tap out ceramic seat.

See Figure 9.

5. Clean seal cavity.

6. Install new seal.

A. Clean polished surface of ceramic seat with clean cloth•

B. Wet outer edge of O-Ring with detergent solution.