ELECTRICAL

,_ Disconnect power before working on pump, motor, pressure switch, or wiring.

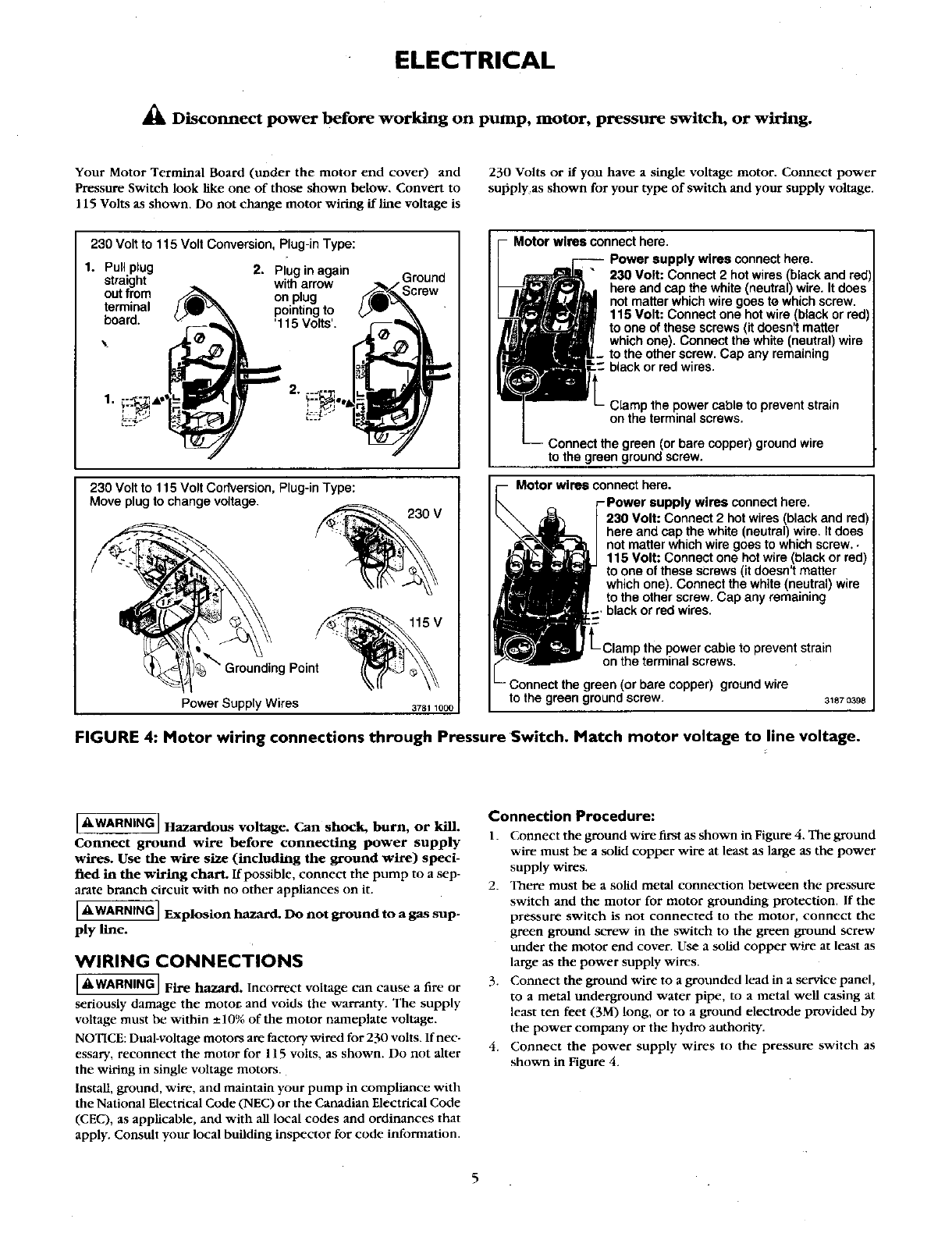

Your Motor Terminal Board (under the motor end cover) and 230 Volts or if you have a single voltage motor. Connect power

Pressure Switch look like one of those shown below. Convert to supply as shown for your type of switch and your supply voltage.

115 Volts as shown. Do not change motor wiring if line voltage is

230 Voltto 115 Volt Conversion, Plug-inType:

1. Pull plug 2. Plug in again

straight witharrow

out from on plug

terminal pointing to

board. '115 Volts'.

Motor wires connect here.

r wires connecthet:e.

230 Volt: Connect 2 hot wires (blackand red)

here and capthe white (neutral)wire. Itdons

not matter which wiregoes to whichscrew,

115 Volt: Connectone hot wire (block or red)

to one ofthese screws(it doesn'tmatter

which one), Connect the white (neutral)wire

- to the otherscrew,Cap any remaining

230 Volt to 115 Volt Conversion, Plug-in Type:

Move plug to change voltage.

Clamp the power cable to prevent strain

on the terminalscrews.

Connect the green (or bare copper) ground wire

to the green ground screw.

Motor wires connecthere,

-Power supply wires connect here.

230 Volt: Connect 2 hot wires (blackand red)

hereand cap the white (neutral)wire, It does

not matterwhich wire goesto whichscrew..

115 Volt: Connectone hot wire (blackor red)

to one ofthese screws(it doesn'tmatter

which one). Connect thewhite (neutral) wire

to the otherscrew,Cap any remaining

blackor red wires,

prevent strain

on the terminal screws,

- Connect the green (or bare copper) ground wire

to the green ground screw. 31870398

FIGURE 4: Motor wiring connections through Pressure Switch, Match motor voltage to line voltage.

[AWARNIN_ Hazardous voltage. Can shock, burn, or kill.

Connect ground wire before connecting power supply

wires. Use the wire size (including the ground wire) speci-

fied in the wiring chart, if possible, connect the pump to a sep-

arate branchcircuit with no other appliances on it.

LAWARNING] Explosion hazard. Do not ground to agas sup-

ply line.

WIRING CONNECTIONS

[AWARNINGI Fire hazard. Incorrect voltage can cause a fire or

m

seriously damage the motor and voids the warranty. The supply

voltage must be within ± 101o of the motor nameplate voltage.

NOTICE: Dual-voltage motors are factory wired for 230 volts, if nec-

essary, reconnect the motor for 115 volts, as shown. Do not alter

the wiring in single voltage motors.

Install, ground, wire, and maintain your pump in compliance with

the National Electrical Code (NEC) or the Canadian Electrical Code

(CEC), as applicable, and with all local codes and ordinances that

apply. Consult your local building inspector for code information.

Connection Procedure:

l. Connect the ground wire first as shown in Figure 4. The ground

wire must be a solid copper wire at least as large as the power

supply wires.

2. There must be a solid metal connection between the pressure

switch and the motor for motor grounding protection. If the

pressure switch is not connected to the motor, connect the

green grotmd screw in the switch to the green ground screw

under the motor end cover. Use a solid copper wire at least as

large as the power supply wires.

3. Connect the ground wire to a grounded lead in a service panel,

to a metal underground water pipe, to a metal well casing at

least ten feet (3M) long, or to a ground electrode provided by

the power company or the hydro authority.

4. Connect the power supply wires to the pressure switch as

shown in Figure 4.

5