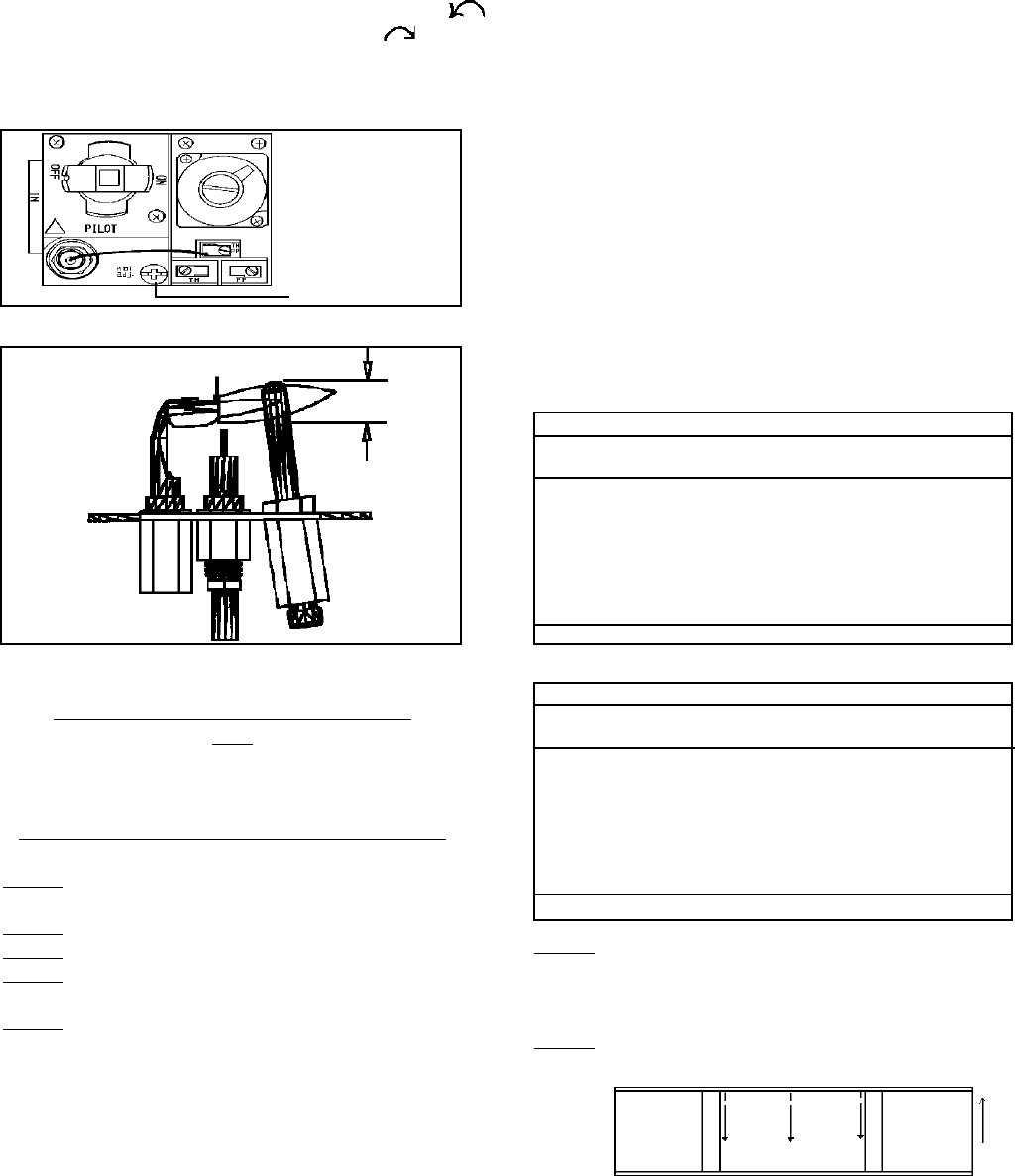

PILOT ADJUSTMENT

The pilot flame can be observed by opening the pilot lighting

hole cover. The pilot flame should surround the top 3/8 to ½

inch of the thermocouple (see Figure 2). If the flame needs

adjusting, first locate the pilot adjustment screw cap and remove.

Adjustment screw is underneath (see Figure 1). To increase the

flame, turn the pilot adjustment screw counterclockwise .

To decrease the flame, turn the screw clockwise . NOTE:

The pilot is unregulated. If incoming line pressure is more than

7” w.c. Natural Gas or 11” w.c. for L.P. Gas, the pilot flame size

should be decreased.

PILOT FLAME

ADJUST-

MENT

Pilot flame

should

envelop

3/8 to 1/2

inch on the

tip of the

generator.

FIGURE 2

RADIANTS AND GLASS PANELS

FOR ALL VCR MODELS

(See Figure 9 – Replacement Parts Section)

INSTALL GLASS AND RADIANTS AS FOLLOWS:

STEP 1. Remove three screws from under top of opening in

bezel frame assembly.

STEP 2. Pull top of bezel down and lay aside.

STEP 3. Remove glass from bottom pad in shipping carton.

STEP 4. Remove carton containing radiants from cavity of

combustion chamber.

STEP 5. Remove radiants from carton and install by tilting

backwards and lifting at the same time into opening. Place

the radiants on the burner radiants supports. The radiants

must be straight. Never operate heater if any radiant is

tilted to front or rear.

Continued

STEP 6. Install glass panels by inserting top edge into upper

retainer and lower into bottom support, and slide glass into

position. Do not allow a crack between the two glass panels.

Never operate heater with either glass missing or cracked.

STEP 7. Re-install bezel by placing bezel tabs over lower front

and swing bezel into position and secure with three screws.

MAIN BURNER ORIFICE

This appliance was shipped from the factory with an orifice

sized to give the correct gas input using the gas for which the

heater was equipped. There may be local conditions, such as

variation in gas pressure or BTU content of the gas, which

may be cause for a change in the orifice. The gas company

supplying the fuel or the installing contractor should check

the gas input rate.

If the rate exceeds the “BTUH INPUT” on the rating plate by

5%, the orifice should be replaced with a smaller orifice by a

qualified technician to reduce the input to the rating plate

value.

The input rate may need to be adjusted for elevation. See the

following charts to determine the correct orifice size for your

Model Number and elevation. These orifice sizes are based

on a heating value of 1020 for Natural Gas and 2500 for L.P.

Gas.

CAUTION: As elevation increases, derating is necessary for

the safe and proper operation of this heater. Do not increase

the Btu input rate by increasing the orifice size or gas

pressure. Allow for elevation derating when sizing gas heating

equipment.

SPECIFIC ELEVATIONS

Model 0 to 2,000- 4,000 - 6,000 - 8,000’

No. 2,000’ 4,000’ 6,000’ 8,000’ 10,000’

VC201 45 47 48 49 50

VC351 35 37 38 40 42

VC501 30 31 31 32 35

VC701 25 27 28 29 30

VCR351 35 37 38 40 42

VCR501 30 31 31 32 35

VCR701 25 27 28 29 30

ORDER KIT #49820 45-1 HIGH ALTITUDE KIT

SPECIFIC ELEVATIONS

Model 0 to 2,000- 4,000 - 6,000 - 8,000’

No. 2,000’ 4,000’ 6,000’ 8,000’ 10,000’

VC202 1.3mm 55 56 56 57

VC352 1.65mm 53 53 54 54

VC502 47 49 49 50 51

VC702 41 42 43 44 46

VCR352 1.65mm 53 53 54 54

VCR502 47 49 49 50 51

VCR702 41 42 43 44 46

ORDER KIT #49820 45-1 HIGH ALTITUDE KIT

NATURAL GAS

L.P. GAS

Page 8

3/8 TO

1/2 INCH

Pilot Adj. Screw

FIGURE 1