6

PYROMASTER® UVHB10 Vent-Free Heaters

20004232

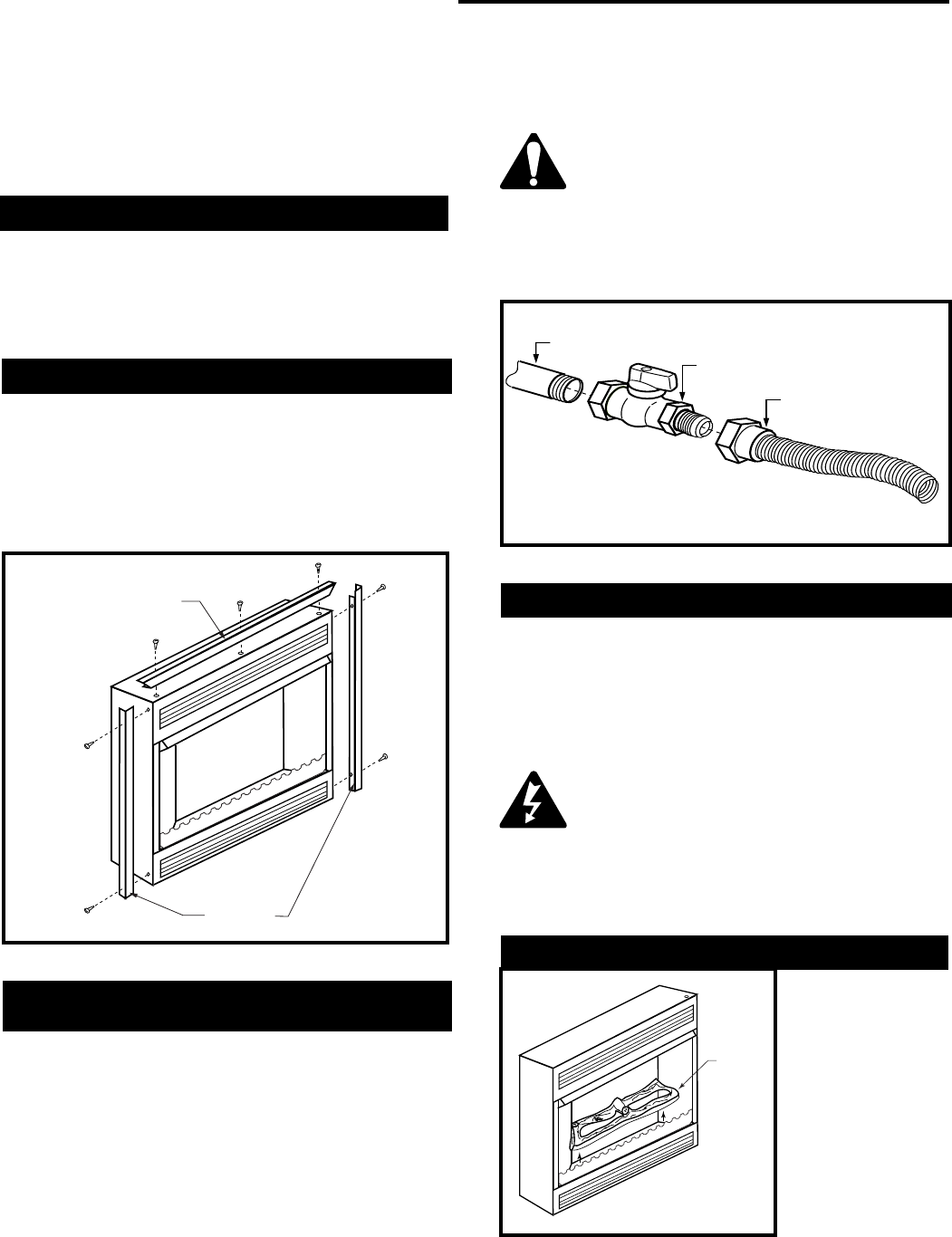

Fig. 8 Typical gas supply installation.

FP297A

1/2" Gas Supply

1/2" NPT x 1/2" Flare Shut-Off

Valve

3/8" Flex Line

(From Valve)

10. Mount the fan on-off control (Rheostat) to the base

with the studs provided and secure with two (2) nuts.

11. Feed the plug through the 4” x 5” hole on the left

side of the heater and plug into a wall receptacle.

12. Reassemble unit by following Steps 1- 3 in reverse

order.

Fan Operation

The FK24 fan has a heat sensor that will not allow the

fan to come on until heater reaches a preset tempera-

ture, approximately 100-120° F. Once the heater

reaches temperature use the speed control knob to turn

fan on and off to adjust fan speed.

Installing Brass Trim

1. Remove brass trim (3 pieces) from carton. Remove

the protective coating from each piece.

2. Using the (2) screws provided, attach the side

pieces to the heater. (Fig. 7)

3. Mount the top trim to the heater. Be sure to overlap

top trim to the front side of the side trim pieces.

Fig. 7 Install brass trim.

FP1115

Brass Trim (Top)

Brass Trim

(Sides)

Final Assembly

Final assembly is accomplished by lifting the mantel

cabinet overtop of the heater behind the brass trim

pieces.

NOTE: The mantel is designed to fit flush to the wall as

a freestanding unit. If desired, it may be secured to the

wall with nails or screws (not provided).

When installed, the heater must be electri-

cally connected and grounded in accor-

dance with local codes or, in the absence of

local codes:

U.S. INSTALLATIONS: FOLLOW LOCAL CODES

AND THE NATIONAL ELECTRICAL CODE, ANSI/

NFPA NO. 70.

Run Gas Line from Its

Source to the Heater

If gas piping from the source to the heater location has

not been accomplished, install the required pipe.

Consult local plumbing code to assure proper pipe size.

The gas pipeline can be brought in through the right

side of the heater.

NOTE: The gas line connection can be made with

properly tinned 3/8" copper tubing, 1/2" rigid pipe or an

approved flex connector, then reduced to 3/8" to the

heater. Because some municipalities have some

additional local codes, it is always best to consult your

local authority. Consult the current National Fuel Gas

Code, ANSI Z223.1

Always check for gas leaks using a 50/50

soap and water solution. Apply water/soap

solution with a brush -

do not over apply.

NEVER!

test with an open flame.

The gas control is equipped with a captured

screw type pressure test point, therefore it is not

necessary to provide a 1/8" test point up stream of the

control.

UVHB10 Logset

The UVHB10 is

shipped with the

one piece log in

position. However,

if the log needs to

be removed, let

the log cool, it

may be hot, lift it

straight up . (Fig. 9)

Logset

FP1213

Fig. 9 Remove logset by lifting up. Be

sure logset is cool before handling.