2

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

Important Notices About Safe Burner Operation

Storage Store the burner inside. Exposure to the elements can damage the burner.

Qualifications Adjustment, maintenance, and troubleshooting of the mechanical parts of this

unit should be done by people with good mechanical aptitude and experience

with combustion equipment.

Replacement Parts Order replacement parts from Eclipse only. Any customer-supplied valves or

switches should carry UL, FM, CSA, and/or CGA approval where applicable.

Operator Training The best safety precaution is an alert and competent operator. Thoroughly in-

struct new operators so they demonstrate an adequate understanding of the

equipment and its operation. Regular retraining must be scheduled to maintain a

high degree of proficiency. The operator must have easy access to this Informa-

tion Guide at all times.

1.0 Burner Operating Parameters & Requirements

Applications Eclipse Air Heat Burners are line type burners ideal for generating large vol-

umes of clean, hot air. Applications include ovens, dryers, fume incinerators, and

similar industrial equipment.

The “AH” models feature an integral combustion air blower mounted on the back

of the burner’s steel case. By supplying the correct air volume and pressure to

the burner, the blower allows stable operation over a wide range of duct veloci-

ties without installing a profile plate around the burner.

Capacities & Supply Pressures

See Figure 2.

Burner Environment Weather Protection: Protect burners from the weather.

Combustion Air: Must be free of contaminants. Eclipse strongly recommends

use of a combustion air filter to remove airborne particles. If corrosive fumes or

materials are present in the air, supply the blower with fresh, clean air from an

uncontaminated area of the plant.

Room Openings: If the burner is mounted on the side of the duct, provide at

least one square inch of opening to the outdoors for every 4000 Btu/hr (1.2 kW)

of burner firing rate. This will admit fresh combustion air.

Access: Provide access to the burner for inspection and maintenance.

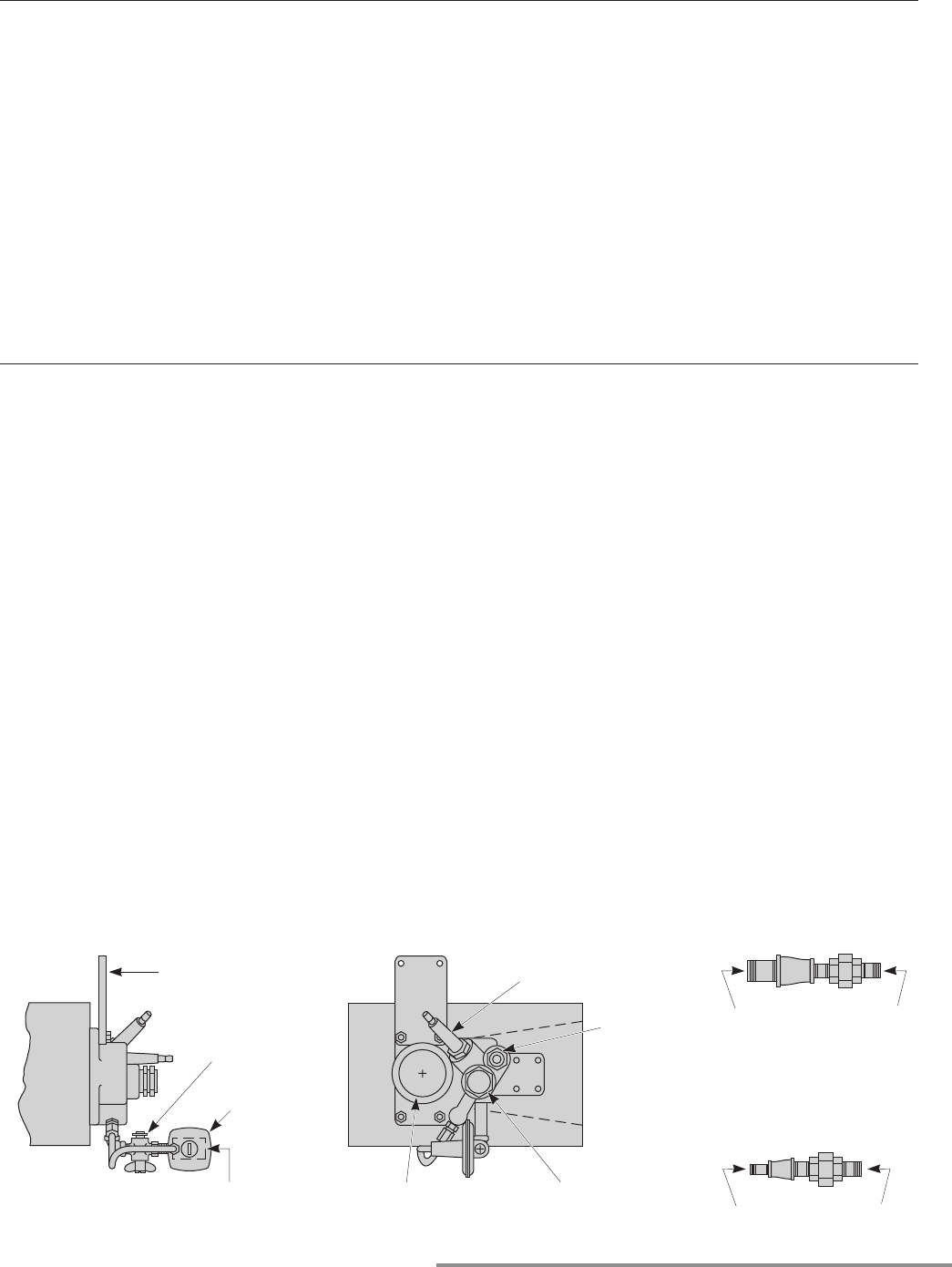

Figure 1–Ignition, Flame Monitoring, and Pilot Components

Scanner

Connection

1/2" N.P.T.

Mount In Place

of Peepsight

3/4"N.P.T.

Scanner Adaptor 109559

For Sizes 440 through 800 AH

Scanner Adaptor 109000

For Sizes through 400 AH

Peepsight

#10509

3/4" N.P.T.

Flame Rod

#13093-3

Spark

Plug

#13047

Main Gas Inlet

2" N.P.T.

Pilot Cock

#12659

Pilot

Regulator

#15027

Mounting

Bracket

Pilot Gas Inlet

1/4" N.P.T.

Scanner

Connection

1/2" N.P.T.

Mount In Place

of Flame Rod

1/4"N.P.T.