12

C

AR

VRT

R

C

V

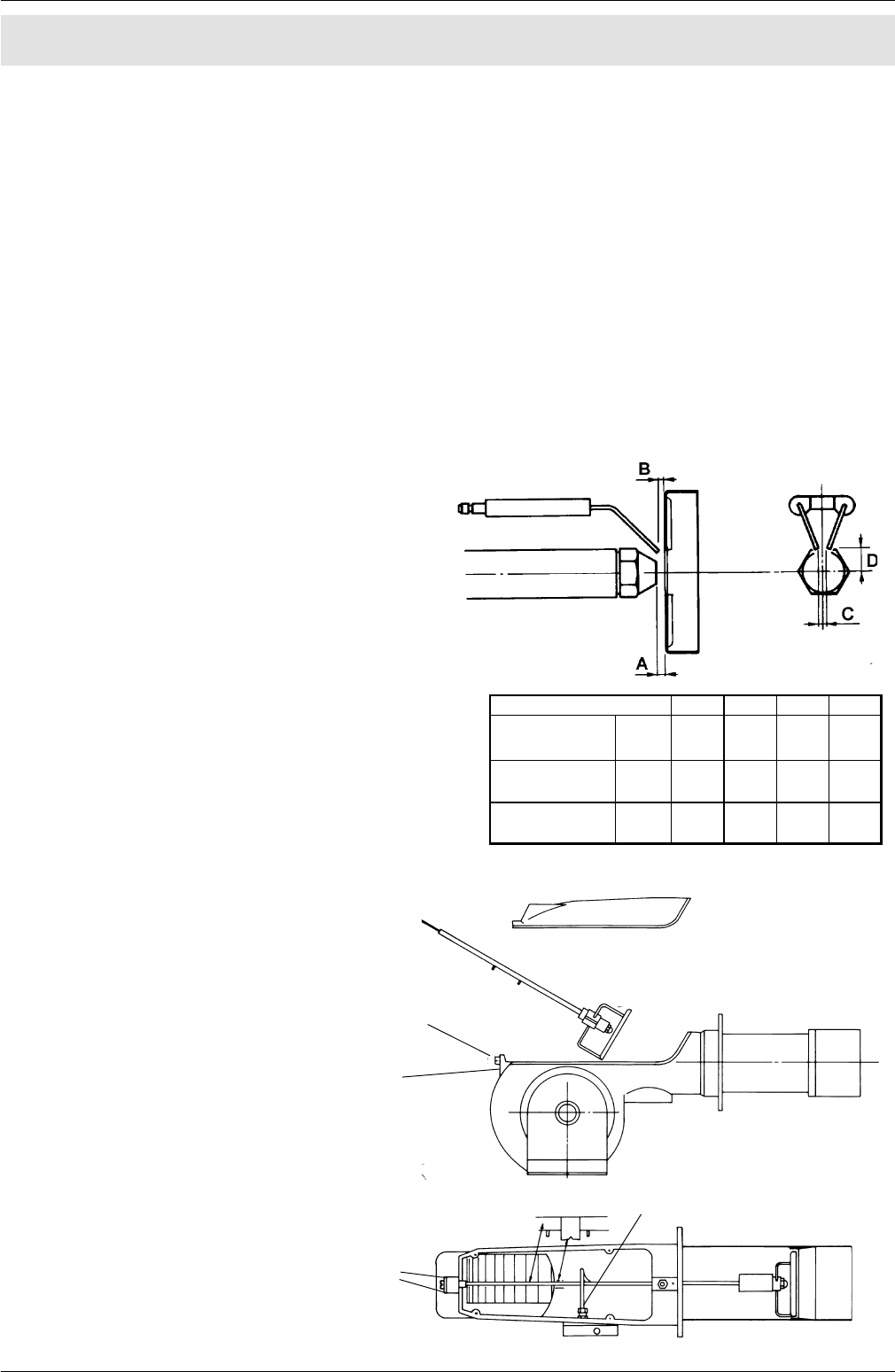

Fig. 13

Fig. 13a

ABCD

60°6446

45°10546

60°8446

45°12546

60°8446

45°12546

G18 SP

PG28SP

PG30TN

PART III: MAINTENANCE

At least once a year carry out the following maintenance procedures.

If servicing is on a seasonal basis, it is recommended at the end of the season; routine sevice should be carried out every

months.

Note: Any operation on the burner must be carried out with the main electricity switched off.

PERIODICAL SERVICING

- Clean and examine the oil filter cartridge and replace it if necessary;

- Examine the condition of the oil flexìble pipeworks and check for possible leaks;

- Clean and examine the filter inside the oil pump;

- Dismantle, examine and clean the combustion head. When reassembling respect the measures reported in table 3.

- Examine the ignition electrodes and their ceramic insulators, adjust and replace if necessary (fig. 13);

- Dismantle and clean the oil nozzle (important: use solvents for cleaning and not metal utensils).

At the end of the maintenence procedures replace the burner, light it and check the shape of the flame:if in doubt replace the

nozzle(s);

where the burner is used intensively it is recommended to replace the nozzles at the beginning of the operating season;

- Examine and carefully clean the flame detector photoelectric cell and replace if necessary. If in doubt light the burner and

then check the detector circuit as shown in Fig. 14.

Correct position of electrodes and combustion

head (G18SP)

Prepare a stable surface where lying the burner

during maintenance.

To gain access to the combustion head and to the

nozzles, loose the screw which lock the blast tube

and remove it from the part that remains fixed to

the boiler.

To guarantee a good ignition, respect the

measures indicated in table 3.

Be sure to lock the screw that fix the electrodes

group, before reassembly the burner.

Removal of the combustion head

(PG25SP - PG30TN)

- Remove the cap C;

- Take out the photoresistance from its housing;

- Unscrew the floating pipe-fitting E from the oil

pipe, using 2 spanners, to avoid to loose the pipe-

firrings from the distribution block;

- Remove the screws V and unscrew the screw

VRT until the threaded rod AR is free;

Remove the complete assembly as shown in

figure 13a.

Note: To re-assemble reverse the order of

procedures descibed above.

MAINTENANCE

Table 3