5

WIRING AND WIRING DIAGRAMS

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accor-

dance with the National Electrical Code, NFPA 70.

ELECTRIC SHOCK HAZARD. Any installation involving

electric heaters must be performed by a qualified

person and must be effectively grounded in accor-

dance with the National Electrical Code to eliminate

shock hazard.

1. Loosen and remove bolts securing the main terminal enclosure

cover on side of unit. Connect heater to line supply wires at the

box lugs located on the contactor according the voltage and fre-

quency specified on the nameplate (see Figure 9). Refer to the

appropriate wiring diagram which also appears on the inside

cover of this enclosure (see Table B and diagrams on page 6).

EXPLOSION HAZARD. Cover joints must be clean

before replacing cover. Do not use any gasket materi-

al on joint surfaces.

2. Use copper conductors only for supply wires. Refer to name-

plate and Table B for size and rating required.

3. Connect supply line ground conductor to the box lug provided

on the base plate below contactor input lugs.

4. The fan motor is factory wired at the same voltage, and phase as

the heating elements. All motors are thermally protected and con-

nected to the main supply contactor. On three phase units, it is

necessary to verify that the fan rotation is correct. Air stream

discharge must be out front of unit. After connecting unit to line

and closing all covers tightly, energize unit momentarily. If air

does not exit front louvers, reverse any two supply leads at the

box lugs on the contactor or at the supply disconnect.

5. Either of two 1 NPT rigid conduit openings with integral stops

may be used for connection to supply line. (See Figure 9 and 10

for locations) Use only NEC approval hazardous locations means

of wiring such as mineral insulated cable and fittings or rigid con-

duit and seal fittings located as required by installation codes.

EXPLOSION HAZARD. All unused conduit openings

must be fitted with plugs that are U.L. recognized for

use in hazardous locations.

6. Heaters may be provided with a built-in control switch and/or

thermostat. If not, they should be controlled by an externally

mounted disconnect switch and/or separately mounted thermostat

as shown in the appropriate wiring diagram on page 6. In case of

malfunction, the personnel in the area should be aware of location

of heater disconnect.

7. Installation must include appropriate over current protection

devices (fusing or circuit breakers) as required by the National

Electric Code in the supply line to the unit. Refer to nameplate for

proper current ratings.

8. To operate heaters from an externally mounted hazardous location

thermostat, a terminal block is provided for connection (Figures 9

and 10). Remove the factory installed jumper across T2 and T3 on

the terminal strip. Wire the thermostat contact leads to these ter-

minals. The built in control transformer supplies the unit with

either 24V or 120V for internal unit operation. This voltage will

appear across the thermostat contacts when they are open. The

minimum thermostat contact rating should be 1 amp @ 120 VAC.

Refer to nameplate for control voltage of unit. The 1/2 NPT con-

duit wiring entry on top of the terminal enclosure should be used

to wire the thermostat to the heater (Figure 10).

9. Protection against overheating is provided by a manual reset limit

control located within the heat exchanger wiring compartment.

(Figure 9) Activation of the control will open the control circuit

and energize the pilot lamp (if supplied). If normal airflow is

restricted, or stopped, the unit will be cycled off by the manual

reset cutout. The manual reset limit control is also designed to

shut down the unit completely if the fluid level is low or other

heater malfunction occurs.

Manual reset limit control must never be bypassed in

the control circuit. If the limit actuates, shut down

unit and investigate cause of abnormal operation. Do

not reenergize until the problem has been corrected.

Users should install adequate back-up controls and

safety devices with their electric heating equipment.

If the back-up controls are to be located in the haz-

ardous area, they must be approved for use in the

class of location. Where the consequences of failure

may be severe, back-up controls are essential.

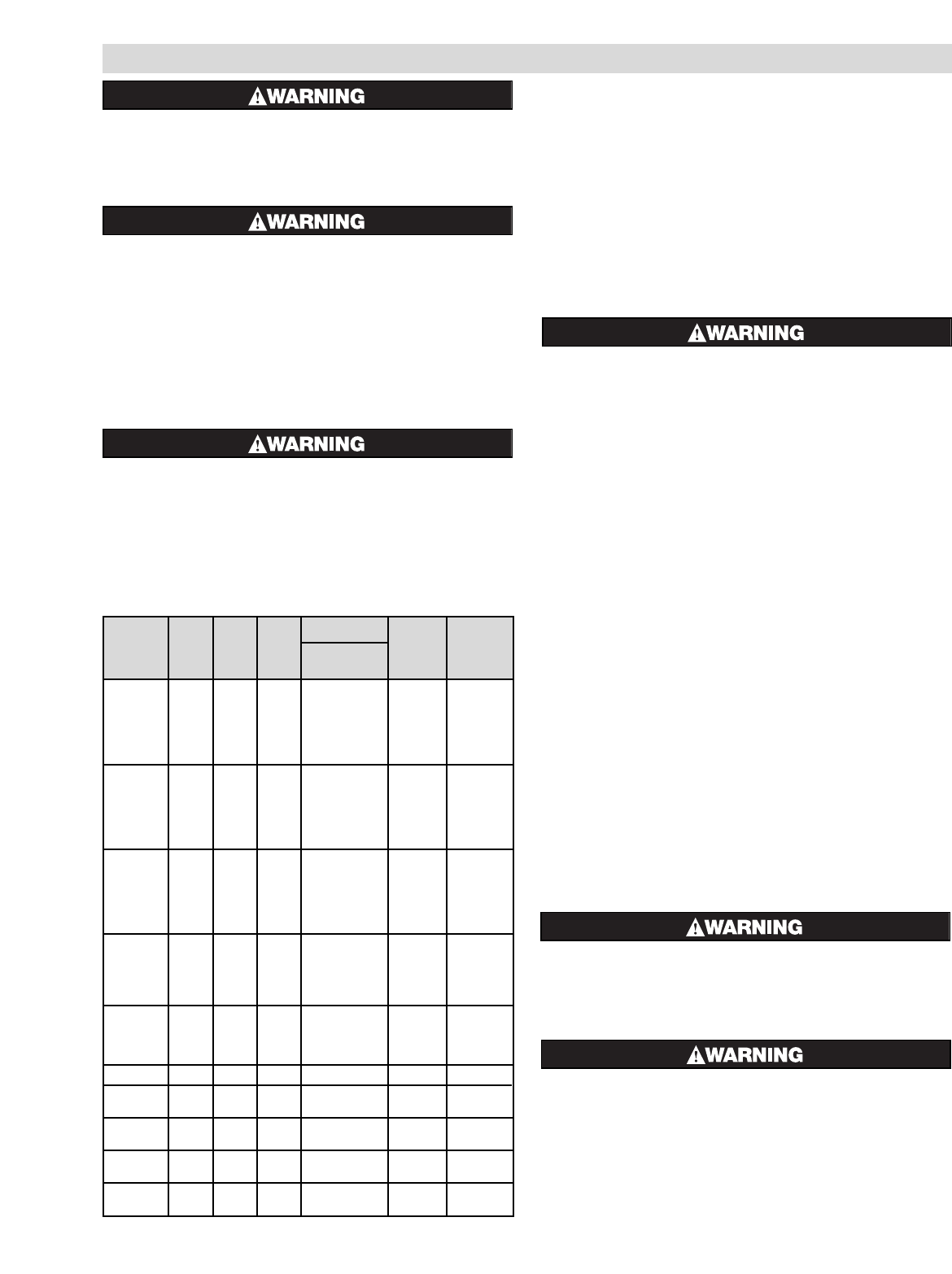

Supply Wire

90˚C Size Max Fuse Wiring

Model kW Phase Volts (ga) Amps Diagram #

CXH-A-03 3 1 208 10 25 I

CXH-A-03 3 3 208 12 15 II

CXH-A-03 3 1 240 10 20 I

CXH-A-03 3 3 240 12 15 II

CXH-A-03 3 3 480 12 15 II

CXH-A-03 3 3 575 12 15 II

CXH-A-05 5 1 208 8 35 I

CXH-A-05 5 3 208 10 20 II

CXH-A-05 5 1 240 8 30 I

CXH-A-05 5 3 240 10 20 II

CXH-A-05 5 3 480 12 15 II

CXH-A-05 5 3 575 12 15 II

CXH-A-07 7.5 1 208 6 50 I

CXH-A-07 7.5 3 208 8 30 II

CXH-A-07 7.5 1 240 6 45 I

CXH-A-07 7.5 3 240 8 25 II

CXH-A-07 7.5 3 480 12 15 II

CXH-A-07 7.5 3 575 12 15 II

CXH-A-10 10 3 208 8 40 II

CXH-A-10 10 1 240 4 60 I

CXH-A-10 10 3 240 8 35 II

CXH-A-10 10 3 480 10 20 II

CXH-A-10 10 3 575 12 15 II

CXH-A-15 15 3 208 4 60 II

CXH-A-15 15 3 240 6 50 II

CXH-A-15 15 3 480 8 25 II

CXH-A-15 15 3 575 10 20 II

CXH-A-18 18 3 240 4 60 II

CXH-A-20 20 3 480 8 35 II

CXH-A-20 20 3 575 8 30 II

CXH-A-25 25 3 480 8 40 II

CXH-A-25 25 3 575 8 35 II

CXH-A-30 30 3 480 6 50 II

CXH-A-30 30 3 575 8 40 II

CXH-A-35 35 3 480 4 60 II

CXH-A-35 35 3 575 6 50 II

Table B – Supply Wiring Requirements