Chromalox

®

DIVISION

4

SECTION

MTO-LT

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

MAINTENANCE INSTRUCTIONS

PD441-1

MARCH, 1999

(Supersedes PD441)

161-303567-001

© 2010 Chromalox, Inc.

Type MTO-LT

Pipe Insert Immersion Heater

GENERAL

WARNING: Calculate and allow for thermal expansion.

Pipe insert will expand upon heating. The rear end of the

pipe insert must remain free from the tank wall. Heating

elements will also expand upon heating and must not

extend to the end of the pipe insert.

Chromalox type MTO-LT screwplug immersion heater is designed

for insertion into a 2” or larger pipe.

WARNING: It is the responsibility of the purchaser of the heater to make

the ultimate choice of pipe material based upon his knowledge of the

chemical composition of the corrosive solution, character of the material

entering the solution and controls which he maintains on the process.

Chromalox cannot warrant any electric immersion heater against failure,

if such failure is the result of corrosion due to improper material selec-

tion by the user.

1. Heater Construction Characteristics:

A. High quality resistance wire held in place by compacted

Magnesium Oxide Refractory enclosed in an Incoloy® sheath.

B. Low to High Watt densities.

C. Explosion Resistant/Liquid-Tight E-2 terminal enclosures

are standard.

WARNING: Users should install adequate controls and

safety devices with their electric heating equipment.

Where the consequences of failure may be severe, back-

up controls are essential. Although the safety of the

installation is the responsibility of the user, Chromalox

will assist in identifying equipment options.

INSTALLATION

WARNING: Hazard of Shock. Disconnect all power

before installing heater.

1. Before installing, check your type MTO-LT pipe insert heater

for any damage that may have occurred during shipment.

2. Check to insure that the line voltage is the same as that stamped

on the nameplate.

3. Do not bend the heating elements. If bending is necessary,

consult factory.

4. IMPORTANT: Mount heater in the tank so that the liquid level

will always be above the effective heated portion of the heater (see

Figure 1). If the heater is not properly submerged, it may overheat

and damage the heating elements and create a possible fire hazard

due to excessive sheath temperatures.

5. Where work will pass over or near equipment, additional protec-

tion such as a metal guard may be needed.

Note: Locate Heater as low as possible for maximum liquid storage capacity. Heat

does not move downward.

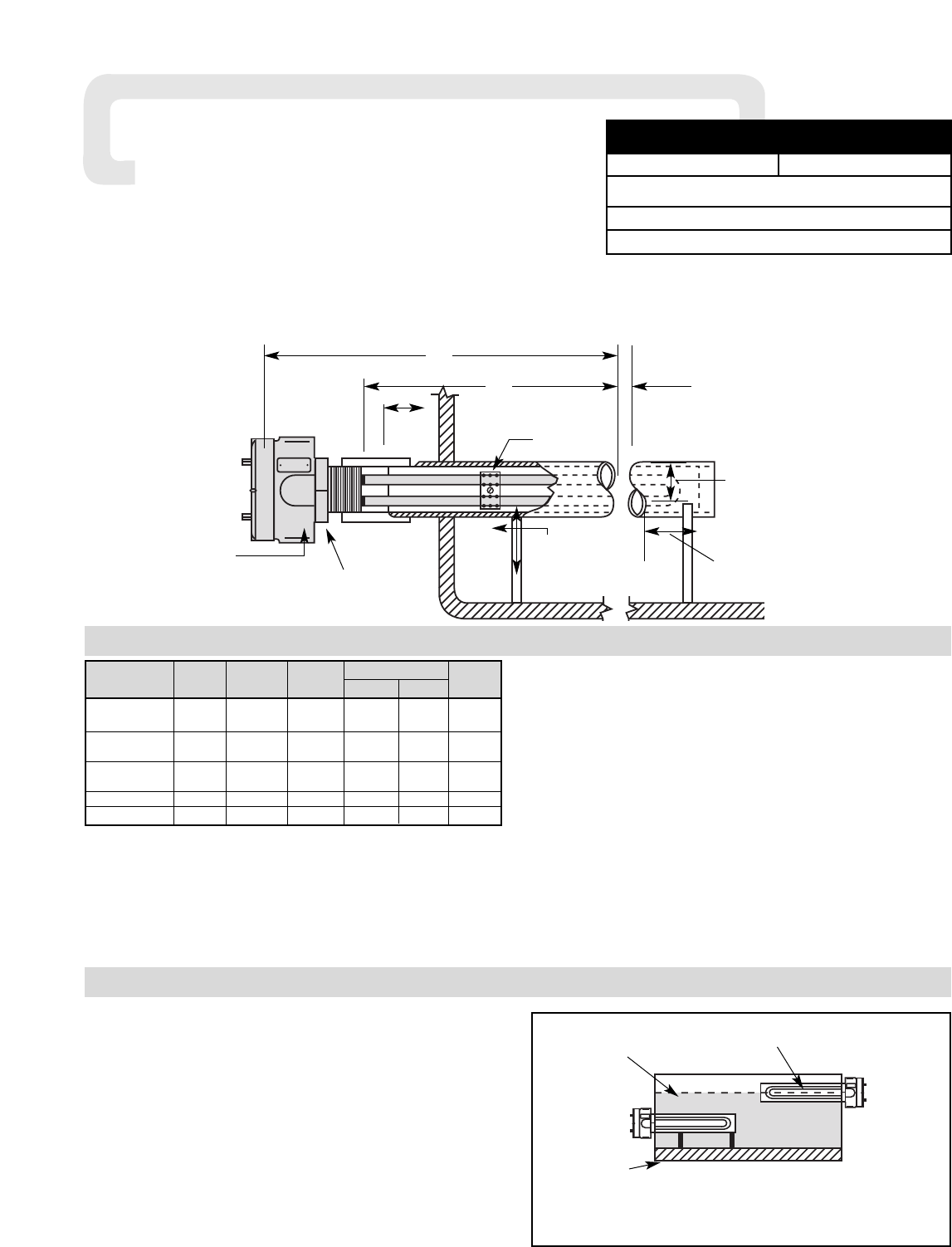

Figure 1 - Open Tank Installation

Dim. (In.) Pipe

Model kW Volts Phase A B Thd.

MTO-241LT 4 240 1 127 120 2

MTO-241LT 4 480 1 127 120 2

MTO-251LT 5 240 1 163 156 2

MTO-251LT 5 480 1 163 156 2

MTO-275LT 7.5 240 1 211 204 2

MTO-275LT 7.5 480 1 211 204 2

MTO-212LT 11.5 480 1 319 312 2

MTO-213LT 13 480 1 367 360 2

Expected Low

Level of Liquid

This Portion of Heater Above Liquid Level and

Exposed to Air Will Lead to Premature Burnout of Element

Expected Maximum

Sediment Level

Type E2

Moisture-Tight

Explosion-Resistant

Enclosure

A

B

Spacer

Expansion Gap

Pipe, Support &

Tank (by others)

Expansion Gap

2-1/16”

I.D. Min.

2-3/8”

Max.

3/4” Pipe Outlet

RIGHT

WRONG