6. In high ambient temperature operations, least corrosive action

and least oxidation to the terminals will occur if the heaters are

mounted with the terminals in the coolest possible ambient,

usually on the bottom or side of the duct.

A. Minimum duct size is “A” or “L” dimension +3/8” and “B”

dimension +1-5/8”.

HAZARD OF FIRE. Since these heaters are capable of

developing high temperatures, extreme care should

be taken to:

A. Avoid installing heaters in an atmosphere containing com-

bustible gases and vapors.

B. Avoid contact between heater and combustible material.

C. Keep combustible materials far enough away to be free of

the effects of high temperatures.

INSTALLATION (cont’d.)

Duct

Air

Air

Temperature Control Instructions

1. A Chromalox thermal cutout or thermostat is recommended for

overheat protection and control of heater and process. Consult

local Chromalox representative.

2. In general, place thermostat sensing element close to the heat-

ing elements, near top of duct, at right angles to the direction of

air flow, and on the downstream side of the heater. Thermostat,

provided with a manual reset button, is separately mounted.

3. For heater protection, the indicated maximum temperature of

the control unit should be 50°F less than the actual maximum

air temperature that will be permitted, to allow for overshoot.

4. Single circuit heater elements may be wired into two circuits to

allow for partial heating and control. It is important to have

thermal control wired into all electric power circuits, so that all

elements may be protected from overheat.

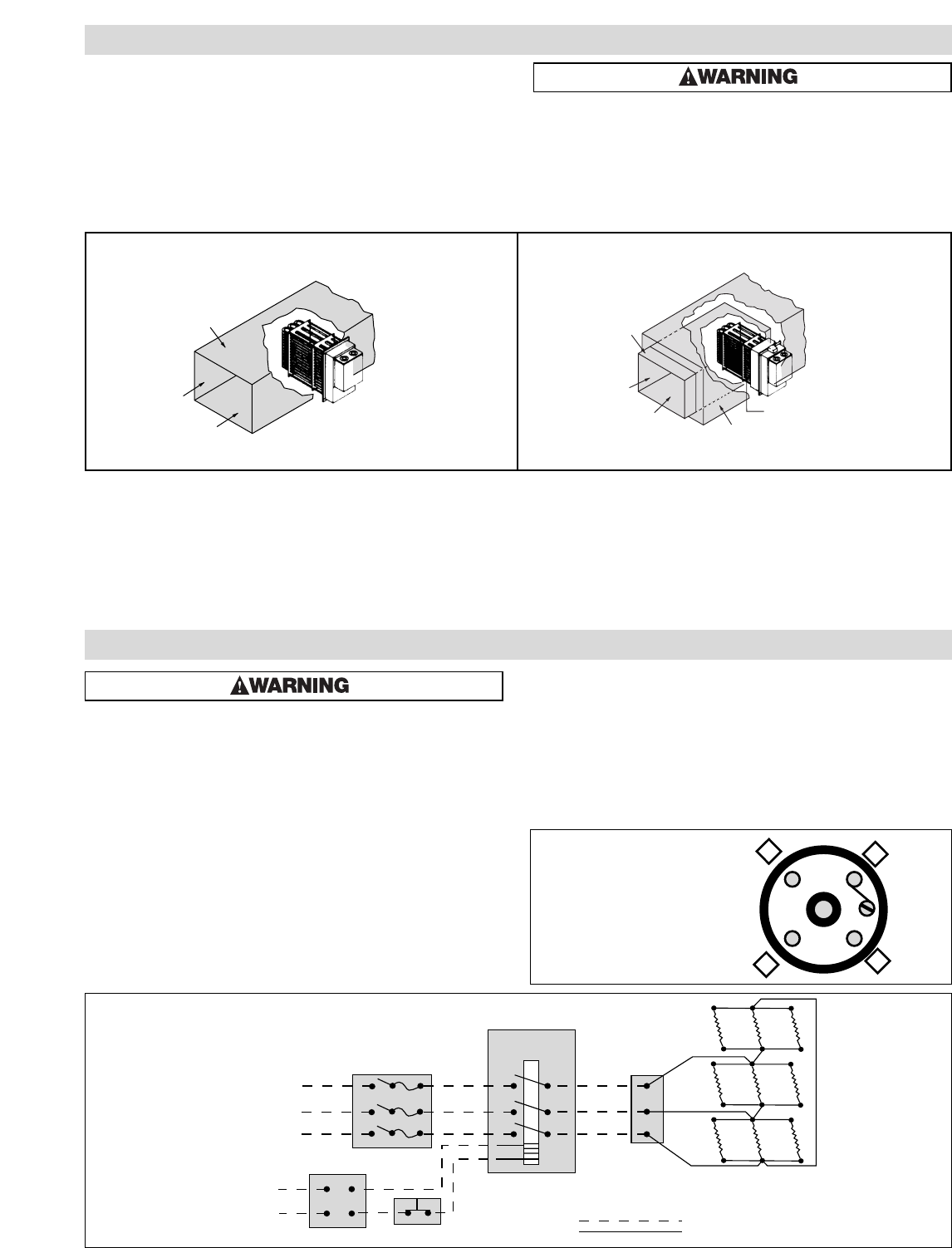

Figure 6 Figure 7

ELECTRIC SHOCK HAZARD. Any installation involv-

ing electric heaters must be performed by a quali-

fied person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. All wiring should be done in accordance with National Electrical

Code and with local codes by a qualified person.

2. Connect air heaters to same line voltage, phase, and frequency

as on heater nameplate.

3. Teflon insulated nickel plated copper wire or bus bar is recom-

mended for power connections to heater terminals and for

wiring runs in heated zones. When ambient temperature in

heated zone exceeds that for which insulated wire is recom-

mended use bare nickel-plated copper with porcelain beads,

tubing or bus bar. Consult local Chromalox representative.

4. Users should install adequate back-up controls and safety

devices with their electric heating equipment. Selection of con-

trols, thermostat, SCR units, contactors and etc. depends on the

degree of accuracy required, reliability, electrical rating of

heater and economic considerations.

5. Below is an example of a standard ADH-015, 480V 3 Ø 15 kW,

wired with recommended back-up controls. (Figure 8)

6.

Individual terminal blocks with 1/4-20 threaded stud type terminals

are provided for each circuit to permit quick positive attachment of

circuit wiring conductors (one terminal block per circuit). (Figure 9)

WIRING

Magnetic

Contactor

Terminal

Block

Fused

Switch

Control Switch

Thermostat

Control

Voltage

120 or 240V

L1

L2

L3

L1

L2

L3

ADH-015

Customer Supplied Wiring

Factory Supplied Wiring

L1

L3

L2

G

✸

X Circuit label indicated here.

Terminal block

(303-027852-001)

Figure 8

Figure 9

ADH-015, 15 kW 480V 3ø, 1 Circuit

(9) - 480V, 1667 Watt Elements

3

Duct

Air

Air

Insulation

(3" max.)

Standoff Colla

r

ADH Low temperature duct heaters — can be fastened directly to the sheet metal duct

work with bolts or sheet metal screws.

ADHT High temperature duct heaters — are generally mounted on field fabricated stand

off supports from the ductwork to position the heater such that the 3” insulation housing

is in the same plane as the duct insulation.