FLUE CONNECTION

AND INFILLING

Make the flue connection with the

special 150°elbow part no.

010/AV12. Please note that this item

is ordered separately from the

appliance. The legs of the elbow may

be cut on site to suit the chimney.

Also note that the legs of the elbow

are different lengths to enable some

situations to be catered for by turning

the elbow around.

The end of the flue pipe must line up

with the centre-line of the chimney,

and must also extend to the point

where the chimney narrows to its

final size. Any large voids must be

filled and flaunched to the flue pipe

to ensure that all soot deposits can be

cleared when the appliance is swept,

and to prevent problems with the

operation of the appliance.

Ensure that the flue pipe is not

obstructed or restricted in any way

and that all joints are well sealed.

Before infilling cover the front of the

appliance to protect it. Ensure that

the flue pipe is central and then fill

the space between the body of the

appliance and the structural

brickwork with vermiculite (e.g.

micafil or similar) concrete. Ensure

that there are no air pockets. The

recommended mix is six volumes of

vermiculite granules to one volume of

Portland cement thoroughly mixed

together. Enough water should be

added so that no more than one or

two drops of water are released when

a handful of the mixture is squeezed.

After filling with vermiculite concrete

flaunch the top of the flue connector

pipe to the chimney with lime

mortar. Ensure that the flue pipe is

well sealed to the chimney.

Make good the hole(s) in the

chimney breast making sure that it is

completely airtight. A typical

installation is shown in Fig. 7.

In most installations it will be

possible to sweep the chimney

through the appliance. If this is not

possible then some alternative means

(such as a soot door), must be

provided.

The free inset method of installation

may be used instead of infilling.

Details are available on request.

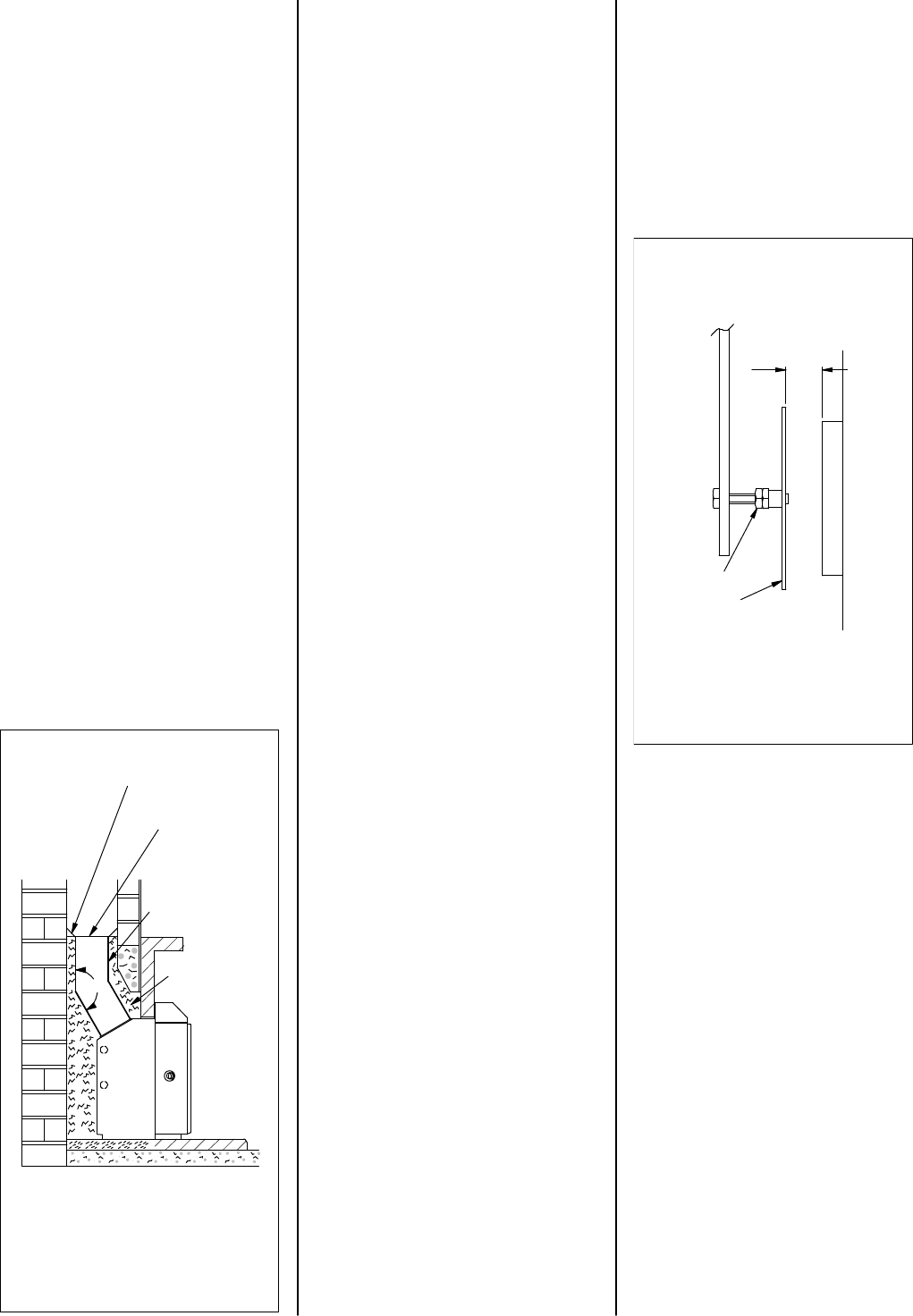

THERMOSTAT

Before lighting the fire check the

cold setting distance of the

thermostat.

With the control knob at the

maximum setting the flap should be

18 mm from the air inlet as shown in

Fig. 8. To adjust the distance slacken

the locking nut and adjust as

necessary. When set correctly

re-tighten the locking nut. Ensure

that the flap opens and closes freely

as the knob is turned.

ASSEMBLY

Fit the side panels and hood onto the

appliance. Instructions for this are

enclosed with the panel pack.

Replace any internal parts previously

removed.

PRE LIGHTING

CHECK

Before initial lighting check the

following points:

1. The bottom grate bars must all be

fitted and should move freely and

easily when the riddling mechanism

is operated.

2. The plates round the sides and

back of the grate must be in position

and sitting correctly.

3. The throat plate must be fitted in

the roof of the appliance.

COMMISSIONING

On completion of the installation and

after allowing a suitable period of

time for the fire cement and mortar

to dry out, the fire should be lit and

checked to ensure that smoke and

fumes are taken from the appliance

up the chimney and emitted safely.

Also check all joints and seals.

On completion of the installation and

commissioning please leave the

operating instructions with the

customer and advise on the use of the

appliance.

FREESTANDING KIT

A freestanding kit is available.

Details of dimensions and outputs are

available on request.

Fig. 8. Thermostat Setting

Thermostat Flap

Locking Nut

18mm

150°

0

4

5

1

2

3

Fig. 7. Typical Installation

Vermiculite

Infill

Flaunching

Take Flue Pipe

Up To Narrowest

Part Of Chimney.

Part No. 010/AV12

150° Elbow

Page 9

LA20i 3/99