HOT WATER SYSTEM

The optional add-in boiler which may

be fitted in the appliance has an

output sufficient for domestic hot

water heating. If the boiler is fitted

then the room heating will be

reduced.

The hot water system should be a

gravity circuit and must be correctly

vented as shown in Fig. 6.

The steel boiler in conjunction with a

double feed indirect hot water storage

cylinder to BS:1566 part 1 should be

used in most situations, unless the

appliance is to be fitted in a soft

water area in which case the stainless

steel boiler may be used with a direct

hot water cylinder.

All pipework in the primary circuit

must be 28mm diameter and the flow

pipe must rise continuously from the

boiler to the open vent.

If an indirect cylinder is used then

the primary circuit should be filled

with a suitable inhibitor to prevent

the build up of scale and corrosion.

FITTING THE

OPTIONAL ADD-IN

BOILER

The boiler replaces the rear firebrick

and is reversible so that the 1’’

B.S.P. male tappings may come on

either the left or the right hand side

of the boiler.

The boiler tappings protrude from the

sides of the appliance and it will

therefore be necessary to fit the boiler

into the appliance after positioning

the appliance in the fireplace if the

fire surround is already fitted.

Before fitting the boiler, remove the

front firebars, the side and back fire

plates and the firebricks. Knock out

the knock-outs for the boiler tappings

on the appropriate side of the firebox.

Remove the backnuts and fibre

washers from the boiler tappings and

fit the boiler into the appliance. Place

the fibre washers over the tappings

on the outside of the appliance and fit

the backnuts, ensuring that the boiler

is held tightly against the rear inside

face of the appliance and that the top

edge of the boiler is level or runs

uphill to the flow tapping.

When re-fitting the firebricks, note

that the short side firebrick supplied

with the boiler must be fitted on the

same side as the boiler tappings. One

of the original side firebricks is fitted

on the other side, and the rear

firebrick is discarded. The firebricks

must be fire cemented into position,

wetting the firebox will improve the

adhesion.

Replace the back fireplate, the side

fireplates, the front firebar and the

throat plate.

Connect the boiler to the heating

system ensuring that the flow pipe

rises from the boiler. Fill the system

with water and check for leaks.

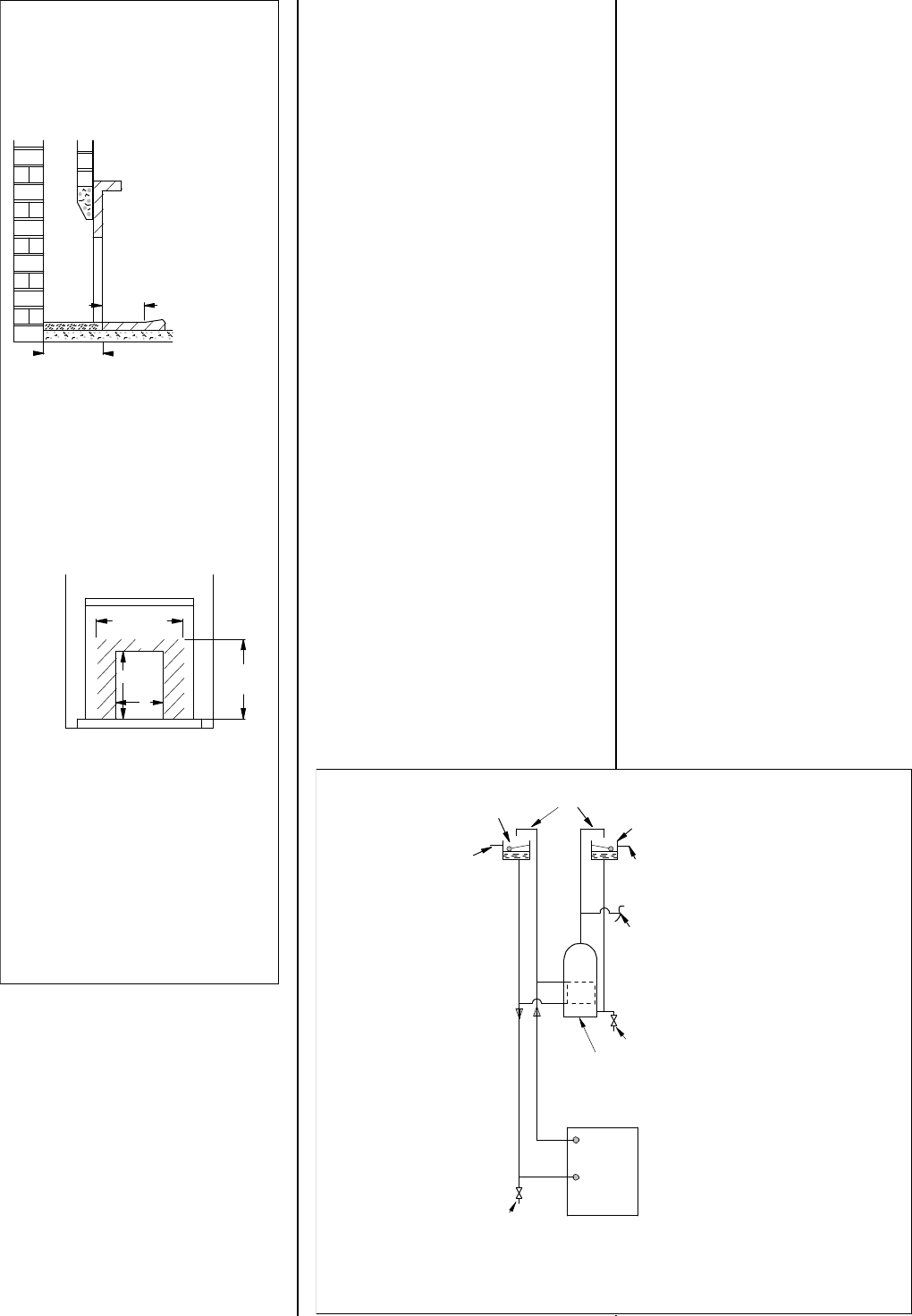

Drain Cock at Lowest Point

Drain Cock

Indirect Hot Water Cylinder

Cold Water Tank

Overflow

Feed and Expansion Tank

22mm Open Vents

Overflow

Domestic Hot Water Draw Off

Gravity Return 28mm

Gravity Flow 28mm

Fig. 6. Typical Gravity Hot Water System

A

B

405 mm

400 mm

Minimum

This Dimension Is The

Minimum Level Area

Required To Enable The

For Overall Sizes Of

Hearth See The

Section Titled "Hearth".

Doors To Be Opened.

Fig. 4. Limiting Dimensions

Of Hearth

Dim. A:

Dim. B:

Min. 405mm (16")

660 mm

The shaded area on the face of

the surround is the minimum flat

area required.

750 mm

Min. 555mm (21 - 3/4")

Max. 575mm (22 - 2/3")

Max. 470mm (18 - 1/2")

Fig. 5. Limiting Dimensions Of

Surround And Opening

Page 8

LA20i 3/99