74

c. Secure the black (–) wire to CCN screw terminal –

on the COMM board.

d. Secure shield wire to CCN screw terminal

SHIELD on the COMM board.

Optional UPC Open Installation

WIRING THE UPC OPEN TO THE MS/TP NET-

WORK — The UPC Open controller communicates using

BACnet on an MS/TP network segment communications at

9600 bps, 19.2 kbps, 38.4 kbps, or 76.8 kbps.

Wire the controllers on an MS/TP network segment in a dai-

sy-chain configuration. Wire specifications for the cable are

22 AWG (American Wire Gage) or 24 AWG, low-capacitance,

twisted, stranded, shielded copper wire. The maximum length

is 2000 ft.

Install a BT485 terminator on the first and last controller on

a network segment to add bias and prevent signal distortions

due to echoing. See Fig. 85-87.

To wire the UPC Open controller to the BAS network:

1. Pull the screw terminal connector from the controller's

BAS Port.

2. Check the communications wiring for shorts and

grounds.

3. Connect the communications wiring to the BAS port’s

screw terminals labeled Net +, Net -, and Shield.

NOTE: Use the same polarity throughout the network

segment.

4. Insert the power screw terminal connector into the UPC

Open controller's power terminals if they are not current-

ly connected.

5. Verify communication with the network by viewing a

module status report. To perform a module status report

using the BACview keypad/display unit, press and hold

the “FN” key then press the “.” Key.

To install a BT485 terminator, push the BT485 on to the

BT485 connector located near the BACnet connector.

NOTE: The BT485 terminator has no polarity associated with

it.

To order a BT485 terminator, consult Commercial Products

i-Vu® Open Control System Master Prices.

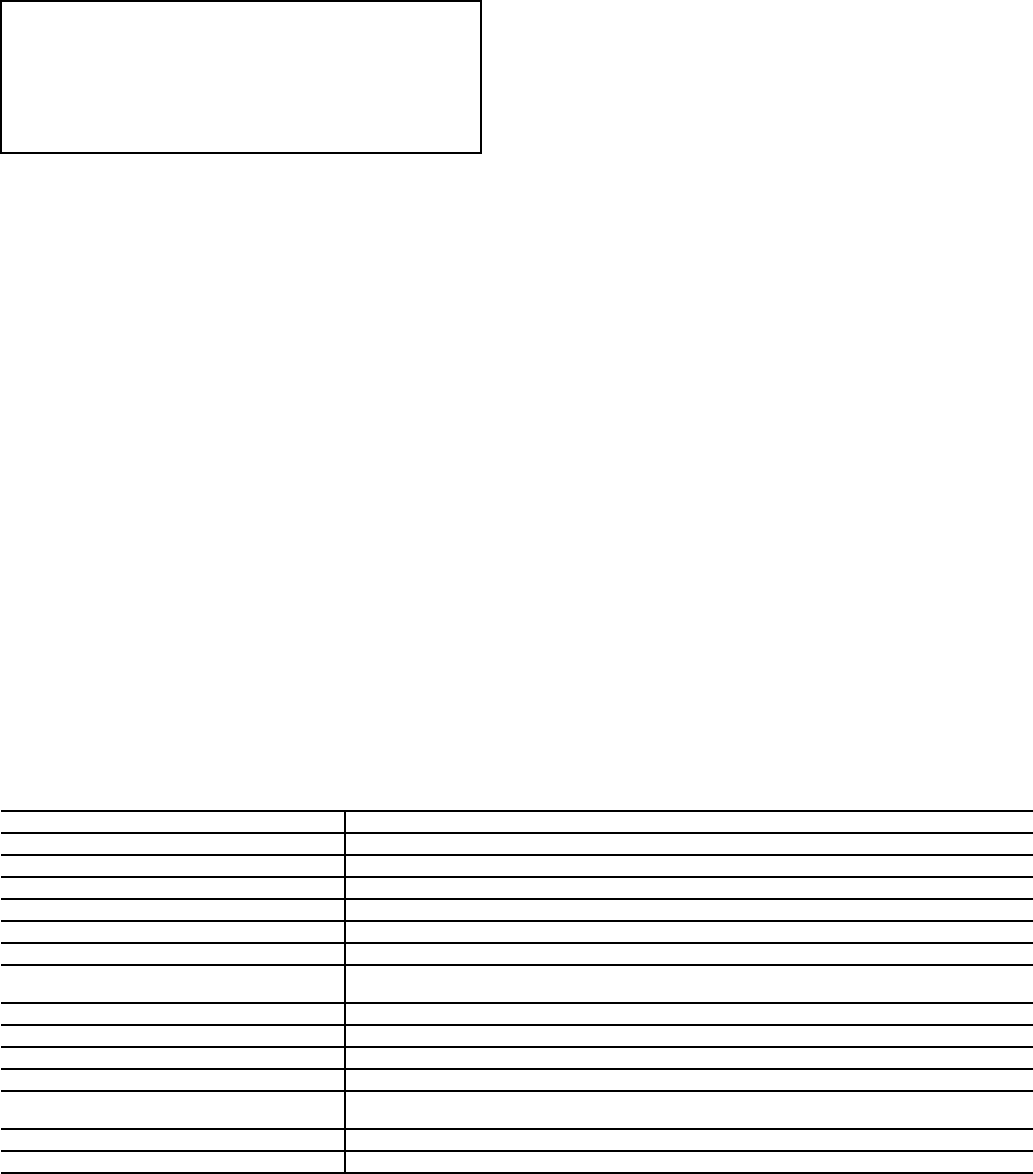

MS/TP WIRING RECOMMENDATIONS — Recommen-

dations are shown in Tables 29 and 30. The wire jacket and UL

temperature rating specifications list two acceptable alterna-

tives. The Halar specification has a higher temperature rating

and a tougher outer jacket than the SmokeGard specification,

and it is appropriate for use in applications where the user is

concerned about abrasion. The Halar jacket is also less likely to

crack in extremely low temperatures.

NOTE: Use the specified type of wire and cable for maximum

signal integrity.

Smoke Control Modes — Rooftop units can be used

for aid in building smoke control in the event of a building fire.

The available functions include: Fire Shutdown, Pressuriza-

tion, Evacuation, and Smoke Purge. These functions are

enhanced when multiple rooftop units are used to zone a build-

ing. See Table 31 and Fig. 82 and 83.

FIRE SHUTDOWN — Fire Shutdown mode terminates all

unit operation (cooling, heating, supply fan, and power

exhaust). This mode prevents recirculation of contaminated air

back into the space. The mode will not allow admission into

the space of unsuitable outside air. See Fig. 82 for wiring.

PRESSURIZATION — Pressurization mode is intended to

keep smoke out of a zone. The factory-installed optional econ-

omizer is required for this function. Pressurization is accom-

plished by the following:

• opening the economizer (option)

• running the supply fan (optional inlet guide vanes open

or optional VFD at normal duct static pressure set point)

• closing the power exhaust dampers (if installed as option

or accessory)

• shutting off the power exhaust fans (if installed as option

or accessory)

Table 29 — MS/TP Wiring Recommendations

LEGEND

IMPORTANT: A shorted CCN bus cable will prevent

some routines from running and may prevent unit from

starting. If abnormal conditions occur, unplug the connec-

tor. If conditions return to normal, check CCN connector,

and run new cable if necessary. A short in one section of

the bus can cause problems with all system elements on

the bus.

SPECIFICATION RECOMMMENDATION

Cable Single twisted pair, low capacitance, CL2P, 22 AWG (7x30), TC foam FEP, plenum rated cable

Conductor 22 or 24 AWG stranded copper (tin plated)

Insulation Foamed FEP 0.015 in. (0.381 mm) wall 0.060 in. (1.524 mm) O.D.

Color Code Black/White

Twist Lay 2 in. (50.8 mm) lay on pair 6 twists/foot (20 twists/meter) nominal

Shielding Aluminum/Mylar shield with 24 AWG TC drain wire

Jacket

SmokeGard Jacket (SmokeGard PVC) 0.021 in. (0.5334 mm) wall 0.175 in. (4.445 mm) O.D.

Halar Jacket (E-CTFE) 0.010 in. (0.254 mm) wall 0.144 in. (3.6576 mm) O.D.

DC Resistance 15.2 Ohms/1000 feet (50 Ohms/km) nominal

Capacitance 12.5 pF/ft (41 pF/meter) nominal conductor to conductor

Characteristic Impedance 100 Ohms nominal

Weight 12 lb/1000 feet (17.9 kg/km)

UL Temperature Rating

SmokeGard 167°F (75°C)

Halar -40 to 302°F (-40 to 150°C)

Voltage 300 Vac, power limited

Listing UL: NEC CL2P, or better

AWG — American Wire Gage

CL2P — Class 2 Plenum Cable

DC — Direct Current

FEP — Fluorinated Ethylene Polymer

NEC — National Electrical Code

O.D. — Outside Diameter

TC — Tinned Copper

UL — Underwriters Laboratories