58

Step 13 — Connect Air Pressure Tubing — Be-

fore options such as the variable frequency drive (VFD) and/or

modulating power exhaust can operate properly, the pneumatic

tubing for pressure sensing must be installed. Use fire-retardant

plenum tubing (field-supplied). All control devices use

1

/

4

-in.

tubing. Tubing must be run from the appropriate sensing loca-

tion (in the duct or in the building space) to the control device

location in the unit.

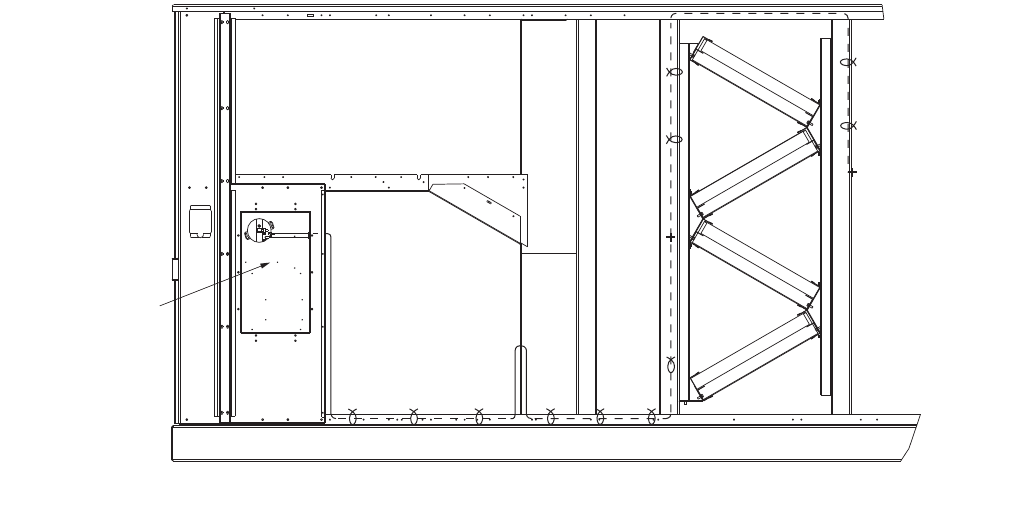

VARIABLE FREQUENCY DRIVE — The tubing for the

duct pressure (DP) control option should sample supply duct

pressure approximately

2

/

3

of the way out from the unit in the

main trunk duct, at a location where a constant duct pressure is

desired.

On these units, the duct pressure is sensed by a pressure

transducer. The pressure transducer output is directed to the unit

control module. On all sizes, the DP transducer is located in the

unit auxiliary control box. See Fig. 44 and 45 for auxiliary

control box location. See Fig. 46-48 for auxiliary control box

details. Use a nominal

1

/

4

-in. plastic tubing.

Refer to appropriate base unit Controls and Troubleshooting

book for instructions on adjusting set points for duct pressure

controls.

MODULATING POWER EXHAUST — The tubing for the

building pressure (BP) control (achieved via the modulating

power exhaust option) should sample building pressure in the

area near the entrance lobby (or other appropriate and sensitive

location) so that location is controlled as closely to design pres-

sures as possible.

These units use a pressure transducer for sensing building

pressure. The BP transducer is located in the unit auxiliary con-

trol box. See Fig. 44 and 45 for auxiliary control box location.

See Fig. 46 and 47 for auxiliary control box details. Use a nom-

inal

1

/

4

-in. plastic tubing.

For instructions on adjusting BP control set points, refer to

the Controls and Troubleshooting book.

RETURN FAN POWER EXHAUST — The tubing for the

building pressure (BP) control (achieved via the return power

exhaust option) should sample building pressure in the area

near the entrance lobby (or other appropriate and sensitive lo-

cation) so that location is controlled as closely to design pres-

sures as possible.

The units use a pressure transducer for sensing building

pressure. The BP transducer is located in the unit auxiliary con-

trol box. See Fig. 45 for auxiliary control box location. See

Fig. 48 for auxiliary control box details. Use a nominal

1

/

4

in.

plastic tubing.

For instructions on adjusting BP control set points, refer to

the Controls and Troubleshooting book.

AUXILIARY

CONTROL

BOX

Fig. 44 — Auxiliary Control Box Location (Sizes 030-050)