14

Indoor Packaged Unit

HVAC Guide Specifications — Section 15787

Size Range: 2 to 5 Tons, Nominal

Carrier Model Number: 50AH

Part 1 — General

1.01 SYSTEM DESCRIPTION

Indoor mounted, electrically controlled packaged

horizontal cooling unit utilizing a hermetic type

scroll compressor.

1.02 QUALITY ASSURANCE

A. Unit shall be certified in accordance with ARI

Standard 210.

B. Unit shall be UL listed and carry a UL label.

C. Unit shall be CSA approved (except 3 ton, 3-phase

units).

D. Unit shall be factory run-tested to ensure proper

performance prior to delivery.

1.03 DELIVERY, STORAGE, AND HANDLING

A. Unit shall be shipped completely assembled and

ready to operate.

B. Unit shall be shipped factory charged with refriger-

ant R-22.

C. Unit shall be stored and handled in accordance with

the unit manufacturer’s instructions.

Part 2 — Products

2.01 EQUIPMENT

A. General:

Factory assembled horizontal, single piece, air

cooled, indoor, ceiling plenum mounted electric

cooling unit. Contained within the unit enclosure

shall be all factory wiring, piping, controls, refriger-

ant charge (R-22), and special features required

prior to start-up.

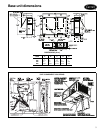

B. Unit Cabinet:

1. Constructed of galvanized steel.

2. Interior shall be insulated with

1

/

2

-in. thick neo-

prene coated fiberglass. Insulation shall be

bonded to interior surfaces by sprayed water

reduceable adhesive.

3. Equipped with 3 same side access panels and

2 bottom hanging removable doors to facilitate

ease of maintenance. Side panels allow access

to the control box, refrigeration components,

and condenser coil. Control box shall be hinged

allowing access to the compressor and pressure

switches. Bottom doors shall allow access to

and easy removal of the condenser and evapo-

rator motors and blower assemblies.

4. Equipped with two

3

/

4

-in. threaded condensate

drain connections below the evaporator coil

and one

3

/

4

-in. threaded connection for con-

denser coil wash down. Connections shall be

factory plugged for field removal.

5. Field splittable through the removal of 4 bolts

and extending refrigerant piping and wiring to

allow remote horizontal or vertical condenser

mounting.

6. Unit shall have an integral hanging bracket

requiring only 4 threaded rods (8 if unit is split)

run to the top flange of the unit for hanging,

eliminating need for external hanger brackets.

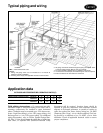

7. Contains junction box for power connection

and opening for routing of control wiring.

C. Fans:

1. Evaporator:

a. Blower shall be of the forward-curved, cen-

trifugal, direct-drive type or belt drive (4 and

5 tons only).

b. Motor shall have permanently lubricated

bearings.

c. Unit sizes 048, 060 shall be available with

an optional 1.5 hp fan motor.

2. Condenser:

a. Blower shall be of the forward-curved, cen-

trifugal, direct-driven type (024 only), or belt

drive (036,048,060).

b. Motor shall have permanently lubricated

bearings.

D. Compressor:

1. Fully hermetic scroll type.

2. Mounted on suitable spring vibration isolators.

3. Equipped with internal line break protection.

E. Coils:

Evaporator and condenser coils shall be of non-

ferrous construction with aluminum fins mechani-

cally bonded to seamless copper tubes with all joints

brazed.

F. Refrigerant Components:

Refrigerant components shall include:

1. Capillary tube feed system.

2. Refrigerant filter-drier.

G. Filter Section:

Filter section shall consist of factory-installed, per-

manent, cleanable air filter, removable from the

same side as the access panels without the use of

tools.

H. Controls and Safeties:

Control system shall include a high-pressure switch,

a low-pressure switch, and a compressor lockout

feature which upon tripping of any safety device

shall prevent compressor from restarting until reset

at the thermostat (on all 3-phase units and 036

single-phase units only).

Time Guard® II device (single-phase only) shall pre-

vent the compressor from restarting for a minimum

of 5 minutes after shutdown.

Guide specifications