56

Installing Flue/Inlet Hoods — The flue and inlet

hoods are shipped in a package taped to the basepan in the fan

section. The flue (outlet) hoods are pre-assembled. The flue de-

flector and inlet hoods require assembly.

The hoods are located on the heating section access panel as

shown in Fig. 59 (sizes 030-050) or Fig. 60 (sizes 055-105).

See Table 18 for a list of parts used to assemble each hood and

quantities of each hood type used with each unit.

1. Remove shipping block-offs and shipping tape from all

openings in the access panel.

2. Attach flue outlet hoods (see Fig. 61) to access panel us-

ing screws provided. Hoods are placed over each com-

bustion outlet.

3. Install flue deflector baffle inside flue deflector hood. See

Fig 62 for sizes 030-050 and 075-105 (V-type deflector).

See Fig. 63 for sizes 055-105 (curve-type deflector). In-

stall flue deflector hood assembly over each flue outlet

hood (installed in Step 2). Observe the offset mounting

hole locations in the deflector hood flanges when attach-

ing hood to panel (see Fig. 64). Holes in the mounting

flange must be at the bottom when attached.

4. Inlet hoods are shipped unassembled and must be assem-

bled on the access panel (see Fig. 65). Flanges of the

hood top and sides should be placed on the inside of the

access panel openings. Install hood top and sides with

screws provided. Attach speed clips to screen and insert

screen into bottom opening of hood. Secure with 3

screws. On large inlet hoods, attach viewport cover over

opening in hood (see Fig. 66). Secure with two screws.

Supply-Air Thermistors (Staged Gas Units

Only) — Supply-air thermistors are a field-installed, factory-

provided component. Three supply-air thermistors are shipped

with staged gas units inside the heating section. Thermistor

wires must be connected to SGC in the heating section. See

Table 19. The supply-air thermistors should be located in the

supply duct with the following criteria:

• downstream of the heat exchanger cells

• equally spaced as far as possible from the heat

exchanger cells

• a duct location where none of the supply air thermistors

are within sight of the heat exchanger cells

• a duct location with good mixed supply air portion of the

unit.

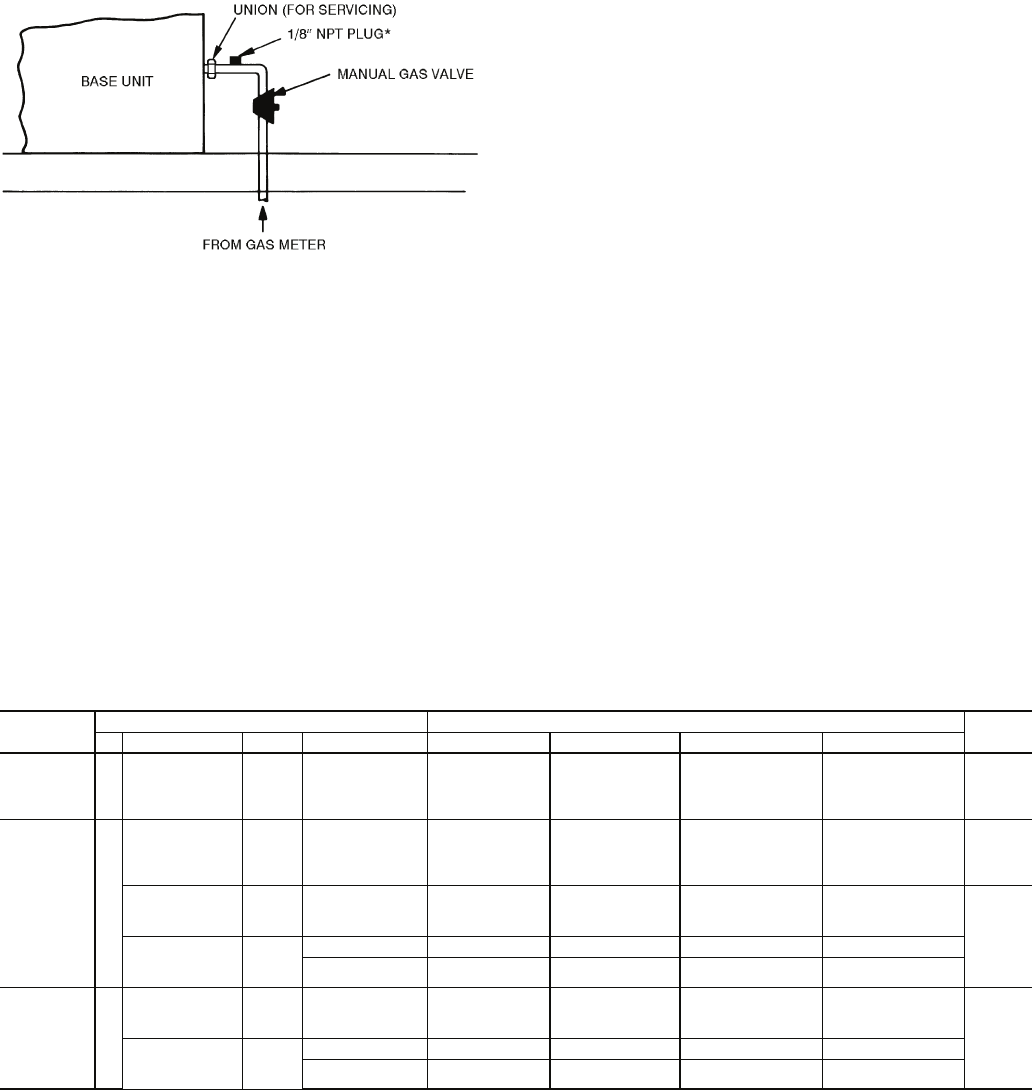

Table 17 — 48Z Series Staged Gas Implementation

LEGEND

*NPT plug is field supplied.

NOTE: Follow all local codes.

Fig. 58 — Gas Piping Details

NO. OF

STAGES

MODEL NUMBER POSITION POINT

HEAT

SIZE

3 5 6,7,8 10 HTSTGTYP CAPMXSTG LIMTHIHT LIMTLOHT

2 stages Z H, K, W, Y 030

035

040

050

ALL Default=0 Default=45 Default=170 F Default=160 F Low

5 stages Z J, L, X, Z 030

035

040

050

ALL Default=1 Default=20 Default=170 F Default=160 F High

H, K, W, Y 055

060

070

ALL Default=1 Default=20 Default=135 F Default=125 F Low

H, K 075

090

105

-,A,B,C,D,E Default=1 Default=20 Default=135 F Default=125 F

G,H,J,K,L,M Default=1 Default=20 Default=130 F Default=120 F

9 stages Z J, L, X, Z 055

060

070

ALL Default=3 Default=15 Default=135 F Default=125 F High

J, L 075

090

105

-,A,B,C,D,E Default=3 Default=15 Default=135 F Default=125 F

G,H,J,K,L,M Default=3 Default=15 Default=130 F Default=120 F

CAPMXSTG — Maximum Capacity per Changes

HTSTGTYP — Heat Stage Type

LIMTHIHT — Limit Switch Thermistor High Temperature

LIMTLOHT — Limit Switch Thermistor Low Temperature